Vertical mill device for milling ceramic raw materials

A ceramic raw material and grinding technology, applied in grain processing and other directions, can solve the problems affecting the discharge of the hopper and the working efficiency of equipment, insufficient grinding of grinding materials, and disorderly discharge methods, etc., to improve service life and increase grinding. time, the effect of improving the crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiment:

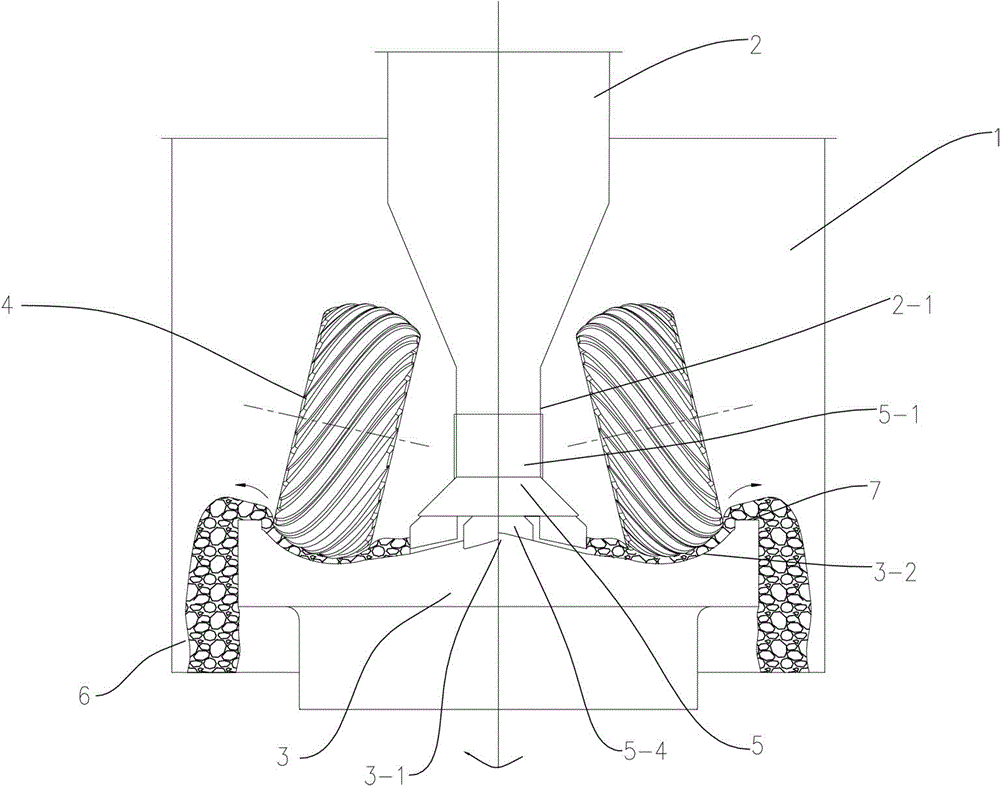

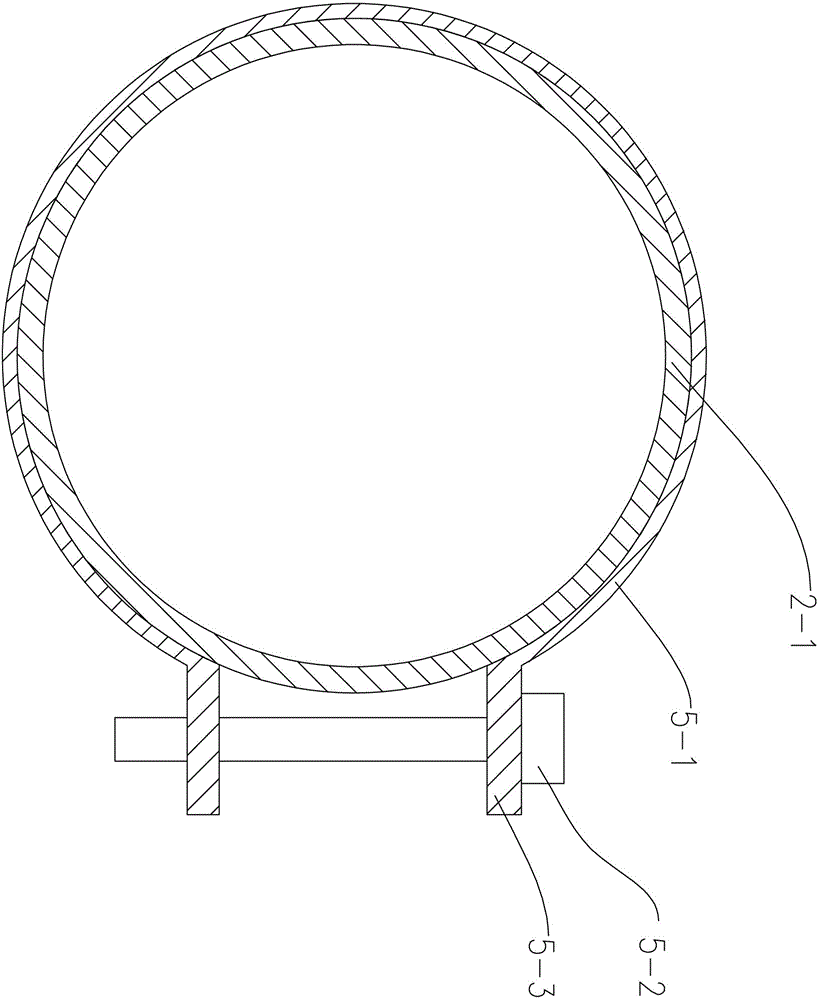

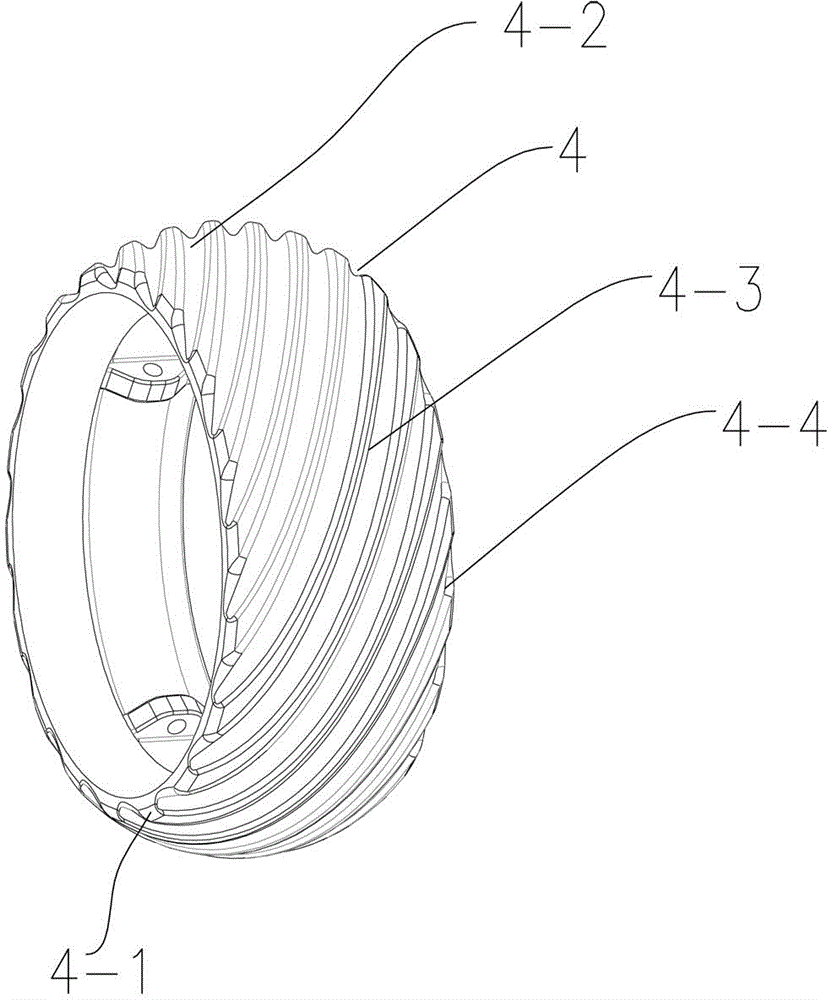

[0013] See attached figure 1 to attach image 3 As shown in this example, a vertical mill equipment for grinding ceramic raw materials described in this embodiment, wherein the tooth shape of the roller skin is an arc-shaped helical tooth, and the direction of rotation is right-handed. The vertical mill device includes a vertical mill shell 1. Material tank 2, grinding disc 3, grinding roller 4 and the scraper device 5 located at the lower end of the material tank 2, wherein the shell 5-1 of the scraper device 5 passes through two connecting plates 5-1 tightened by bolts 5-2 3 is tightly sleeved on the discharge port housing 2-1 at the lower end of the material tank 2, and the two connecting plates 5-3 are located at both ends of the housing 5-1. The lower end of the scraper device 5 is provided with scrapers 5-4 distributed in circular intervals along the bottom of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com