Purification equipment capable of effectively treating dense smoke and dust

A technology for effective treatment and purification of equipment, applied in the field of chemical engineering, can solve problems such as vomiting, plastics that cannot be cleaned, environmental impact, etc., and achieve the effect of thoroughly purifying smoke and dust and avoiding damage to the flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

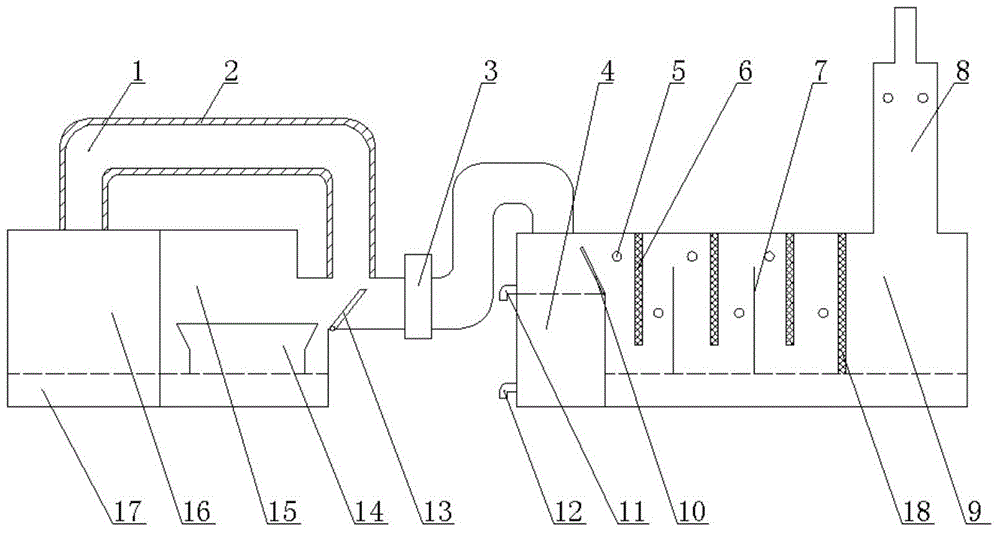

[0018] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0019] A purification device that can effectively treat dense smoke and dust, consisting of a combustion chamber 16, a large particle dust removal chamber 15, a water tank 17, a flue 1, an induced draft fan 3 and a purification chamber 9, wherein the combustion chamber, the large particle dust removal chamber and the purification A water tank is installed at the bottom of the chamber; a flue is installed on the top of the combustion chamber, and the flue is connected to the clean room through an induced draft fan; A guide plate 13 is hinged at the channel opening of the large particle dust removal chamber; a fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com