Continuously variable transmission

A technology of continuously variable transmission and transmission, which is applied in transmission devices, friction transmission devices, belts/chains/gears, etc. It can solve the problems of peripheral speed difference, power transmission efficiency reduction, loss, etc., and achieve friction loss reduction and loss energy change. Small, spin loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

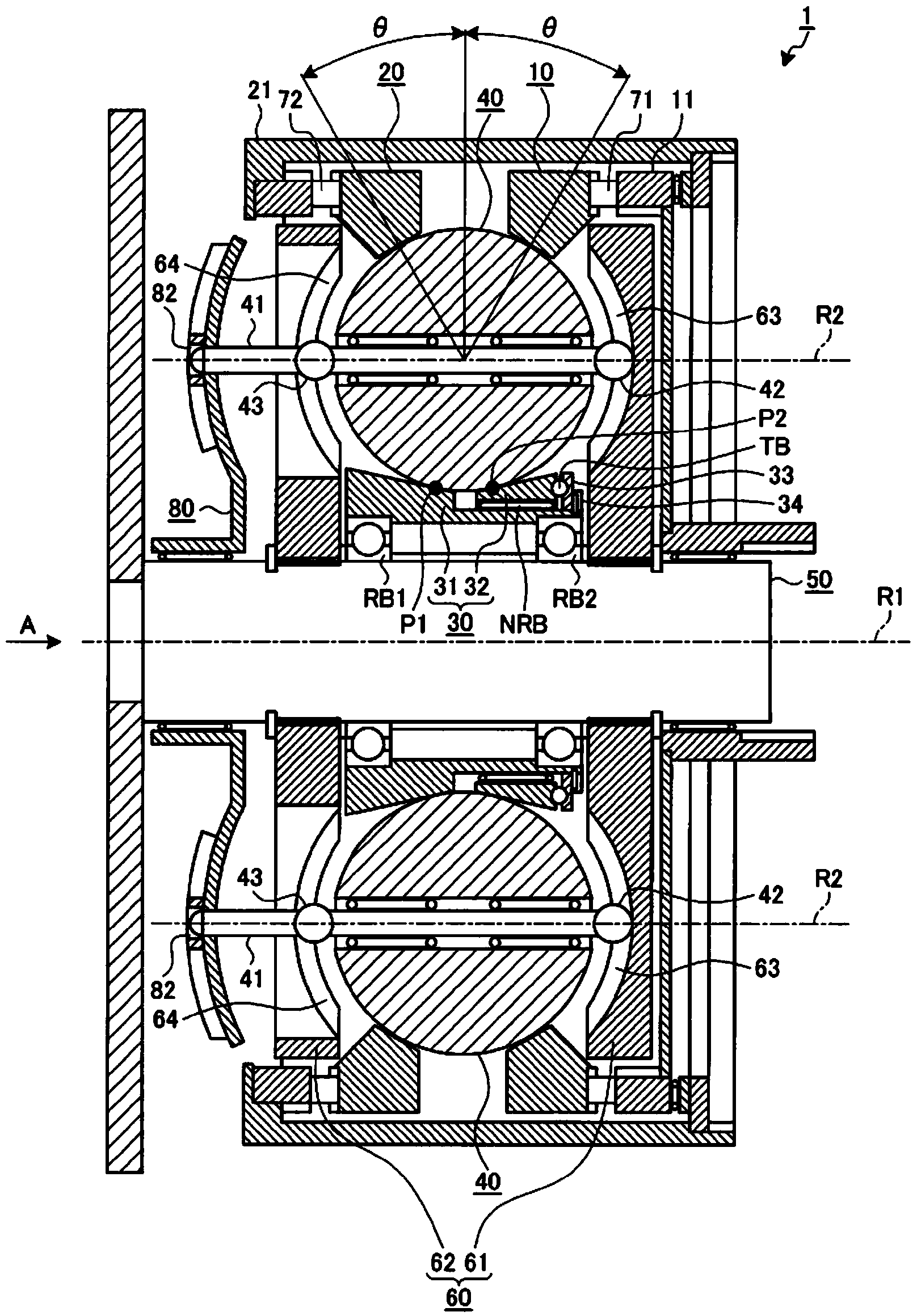

[0030] based on Figure 1 to Figure 6 Embodiment 1 of the continuously variable transmission according to the present invention will be described.

[0031] First, use figure 1 An example of the continuously variable transmission of this embodiment will be described. figure 1 The numeral 1 in the . represents the continuously variable transmission of this embodiment.

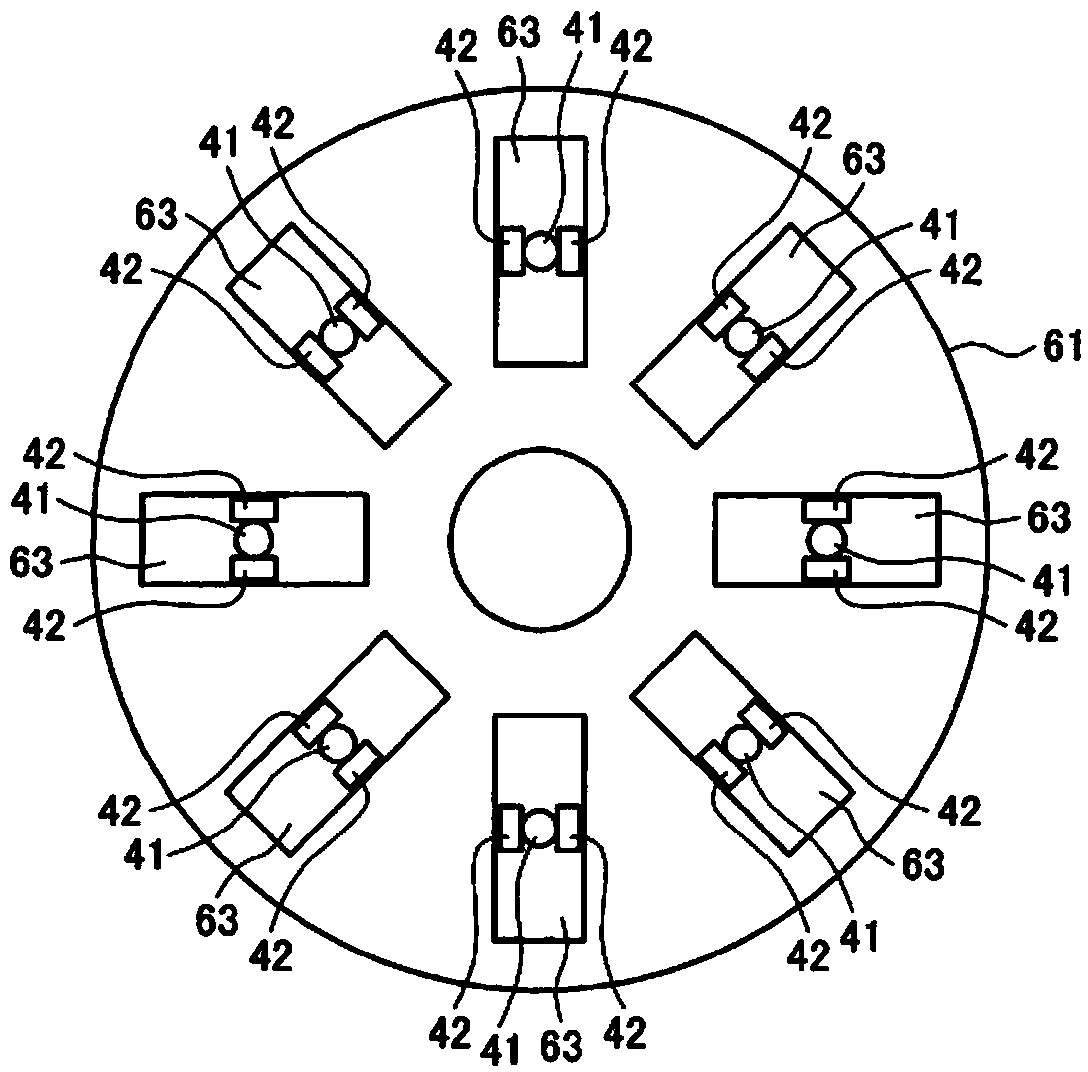

[0032] The continuously variable transmission mechanism constituting the main part of the continuously variable transmission 1 is a so-called traction planetary gear mechanism, and includes first to third rotation elements having a common first rotation center axis R1 and being rotatable relative to each other. 10, 20, 30; a plurality of them are radially arranged around the first rotation center axis R1, and each has another second rotation center axis parallel to the first rotation center axis R1 at a reference position described later. The rolling member 40 of R2; the shaft 50 serving as the transmission sh...

Embodiment 2

[0071] Second, based on Figure 7 to Figure 12 Embodiment 2 of the continuously variable transmission according to the present invention will be described.

[0072] In the continuously variable transmission 1 and the continuously variable transmission 2 of the above-mentioned embodiment 1, in order to reduce the friction loss caused by the rotation difference between the thrust bearing TB and the angular contact bearing AB during deflection (when the transmission ratio γ≠1), it is preferable Lubricating oil is supplied to the thrust bearing TB and the angular contact bearing AB. In this second embodiment, a structure for supplying lubricating oil will be described.

[0073] Figure 7 The reference numeral 3 in represents the continuously variable transmission of this embodiment. This continuously variable transmission 3 is obtained by replacing the sun roller 30 with the sun roller 230 and replacing the shaft 50 with the shaft 150 in the continuously variable transmission 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com