Electronic shogging control system and method used in warp knitting industry

A control system and control method technology, which is applied in general control systems, control/regulation systems, warp knitting, etc., can solve problems such as high failure rate and complex mechanical structure, and achieve cost saving, high displacement precision, and interface friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

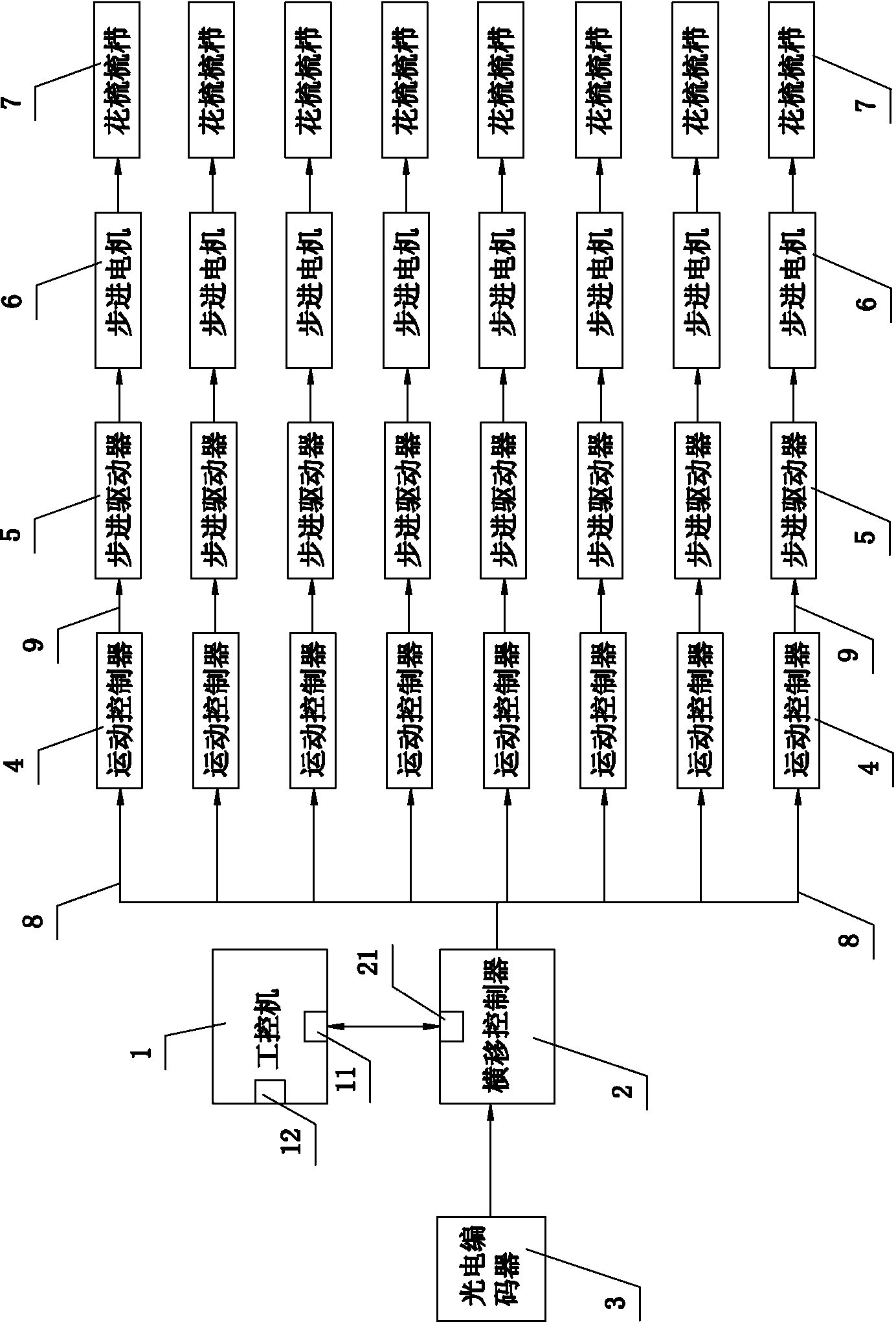

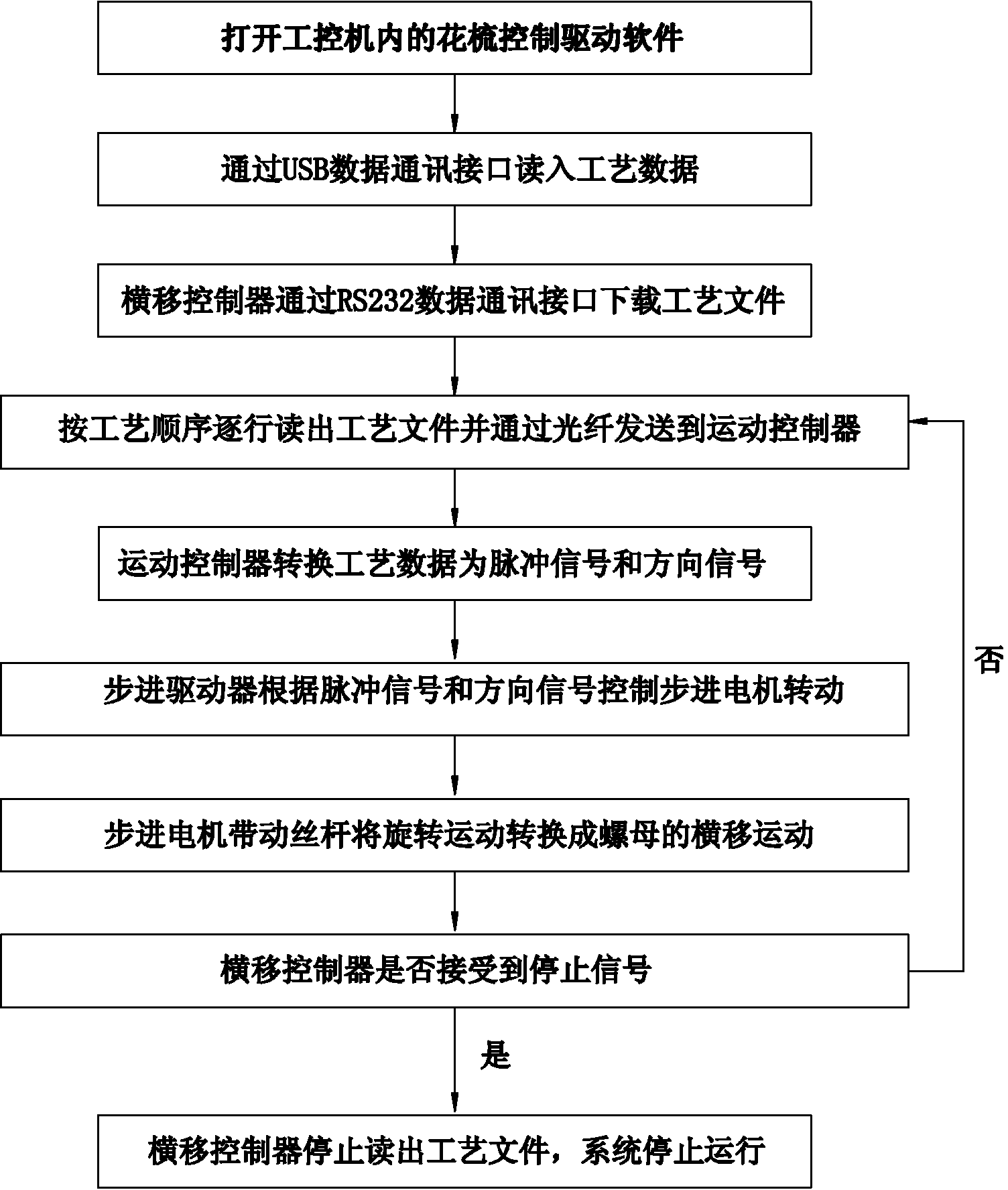

[0032] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0033] refer to figure 1 . An electronic traverse control system used in the warp knitting industry, including an industrial computer 1, a traverse controller 2, a photoelectric encoder 3, a motion controller 4, a step driver 5, a step motor 6, and a flower comb 7 . The industrial computer 1 is an ordinary industrial control computer with a corresponding flower comb control driver software inside, and the industrial computer 1 is provided with a data communication interface 11 capable of data communication with the traverse controller 2 and a user interface 11. The data communication interface 12 for reading process documents, wherein the data communication interface 11 is an RS232 data communication interface, and the data communication interface 12 is a USB data communication interface. The photoelectric encoder 3 is used to determine the position in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com