Method for identifying slagging trend of different mineral components in coal ash

A technology of mineral composition and coal ash, which is applied to the analysis of materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0020] The method for identifying the slagging tendency of each mineral component in the coal ash using CCSEM technology disclosed in this embodiment, the specific steps are as follows:

[0021] (1) The raw coal selected in this example is Datong bituminous coal, and the coal ash after pulverized coal is burned in a laboratory-scale settling furnace at 1300 °C in an air atmosphere is collected;

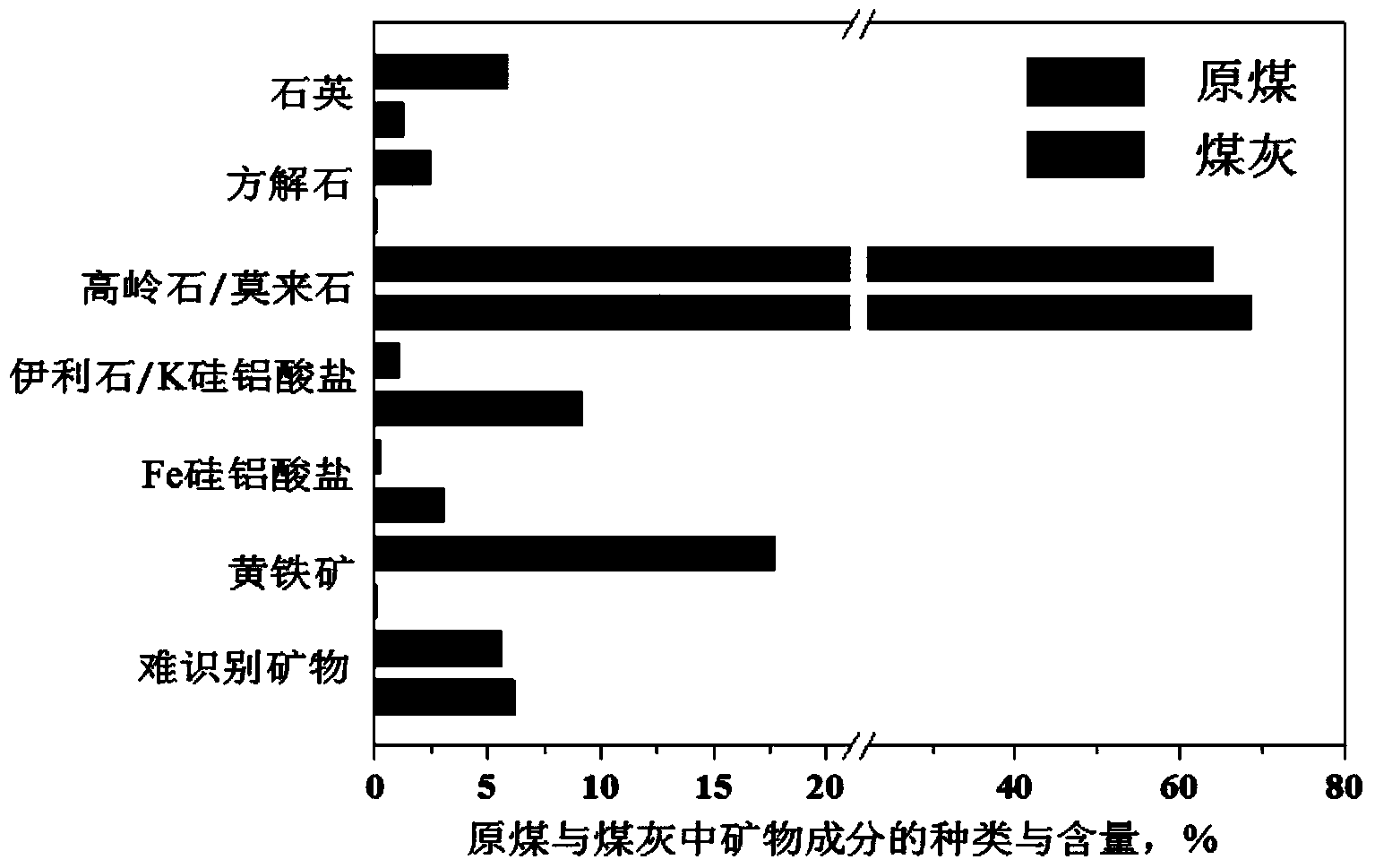

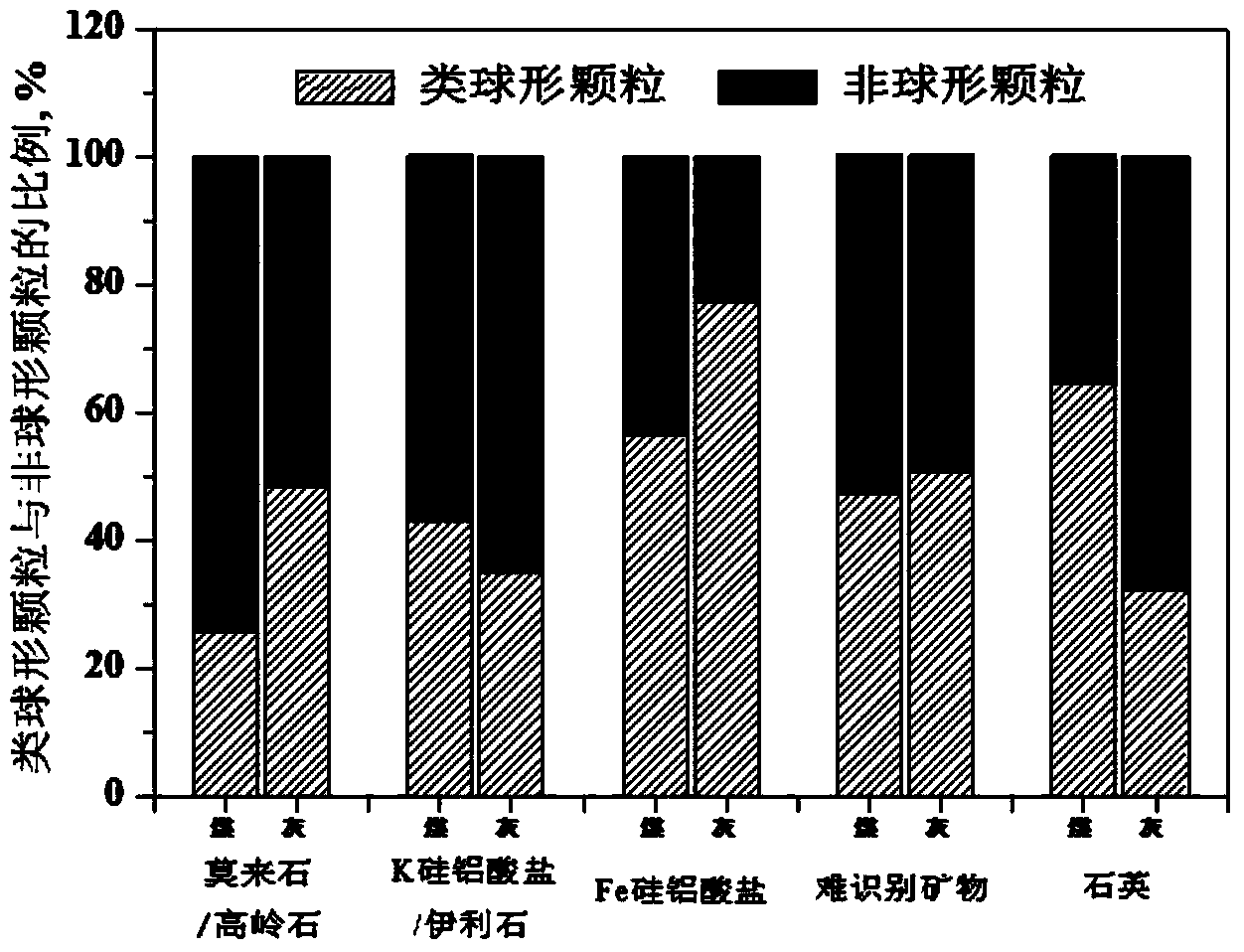

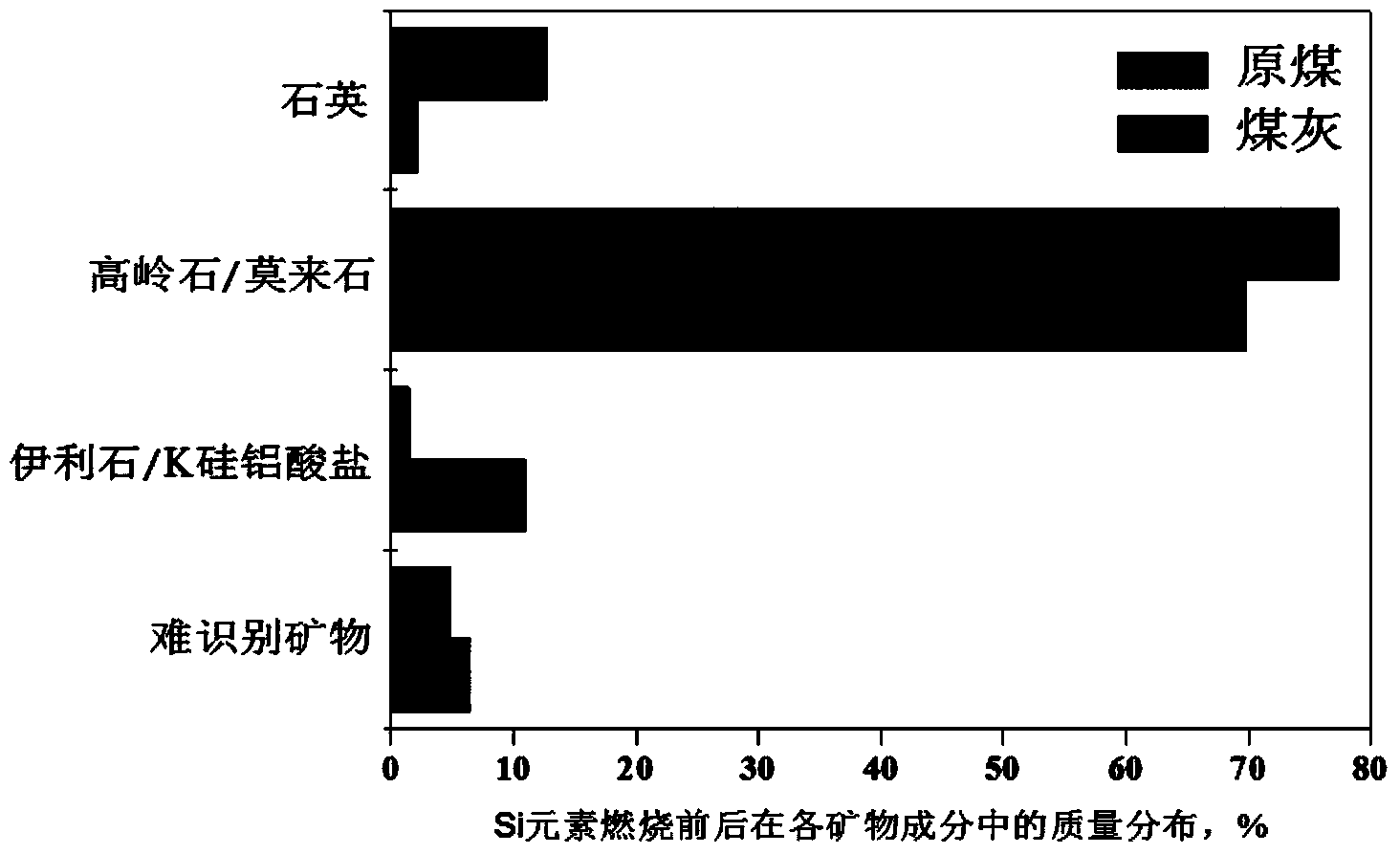

[0022] (2) Use CCSEM technology to analyze the content of various mineral components in raw coal and coal ash, such as figure 1 As shown, the specific method of analysis is: uniformly mix coal powder or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com