Combined type vacuum oven suitable for being used in lithium battery processing process

A processing and vacuum oven technology, applied in the direction of non-aqueous electrolyte batteries, sustainable manufacturing/processing, electrolyte battery manufacturing, etc., can solve the problems of inability to solve the problem of gas leakage, unsuitable for use, etc., to achieve convenient disassembly and assembly, and to avoid leakage gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

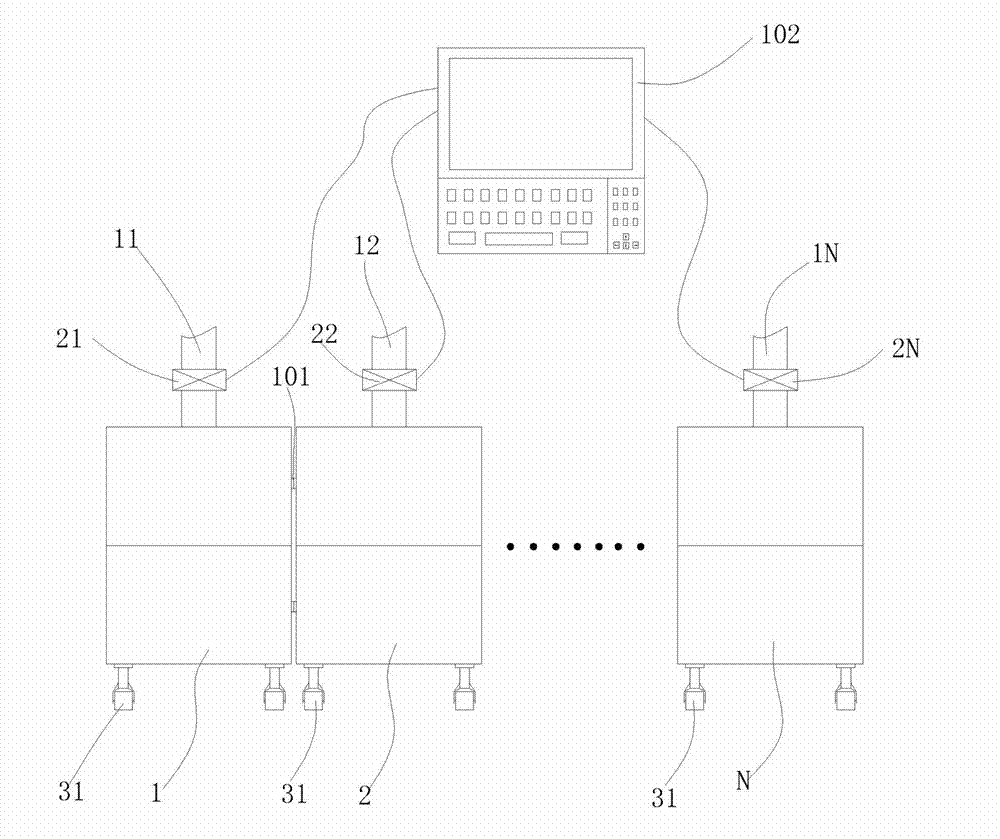

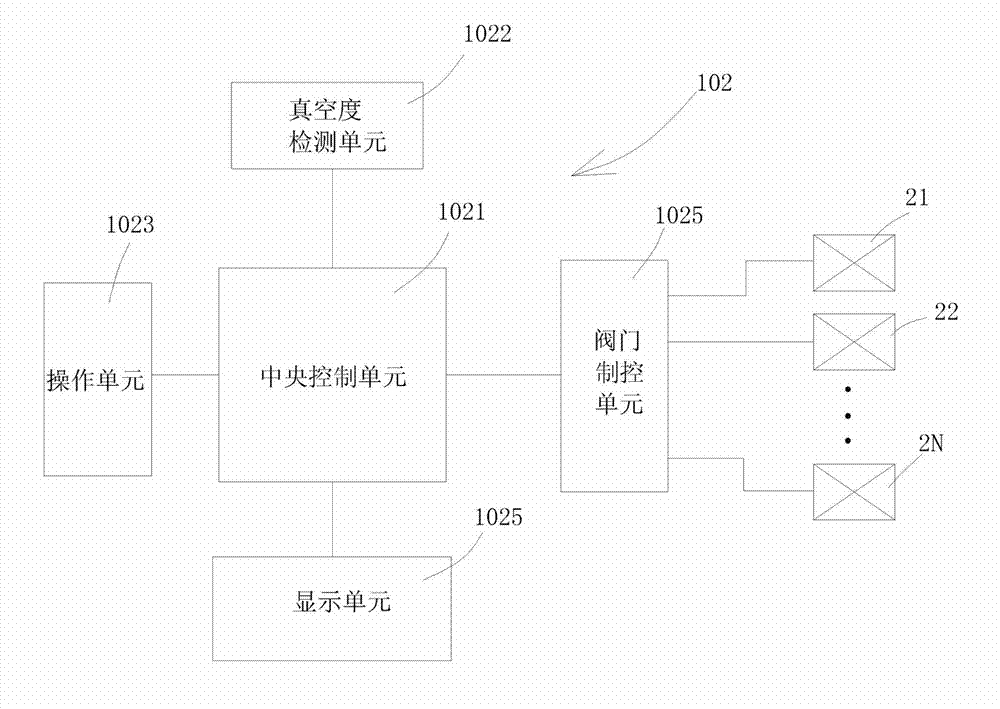

[0015] See figure 1 and figure 2 , figure 1 and figure 2 What is disclosed is a combined vacuum oven suitable for use in lithium battery processing, including at least two boxes (the first box 1, the second box 2...the Nth box N in this embodiment) ), each of the boxes includes an outer box and a working box, the working box is set inside the outer box, and all the working boxes are connected to the vacuum source through their respective pipelines 11, 12... 1N connected to each other; adjacent boxes are connected by at least one connecting member 101 to form an oven group; each of the working boxes is connected to a vacuum source through controllable valves 21, 22... 2N; a centralized control unit 102, the The output end of the centralized control unit 102 is electrically connected to the controllable valves 21, 22...2N on each of the working boxes, and when the vacuuming of the working boxes is completed, the centralized control unit 102 immediately closes the valves C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com