Nailless preservative wood installation structure

A technology for installing structures and anti-corrosion wood, which is applied to building structures, floors, buildings, etc. It can solve problems such as difficulty in ensuring flatness, discounting of overall effects, and impact on appearance, so as to achieve safe and firm construction, solve common quality problems, and overall beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

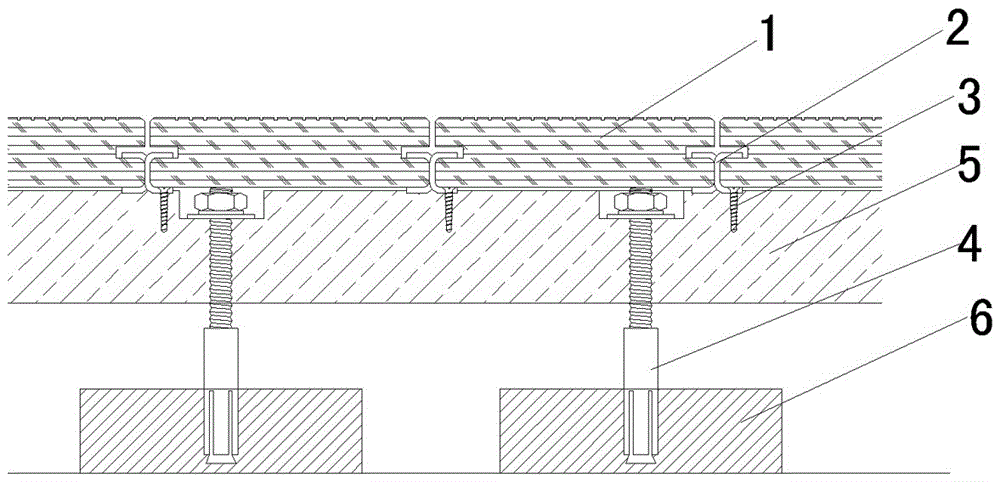

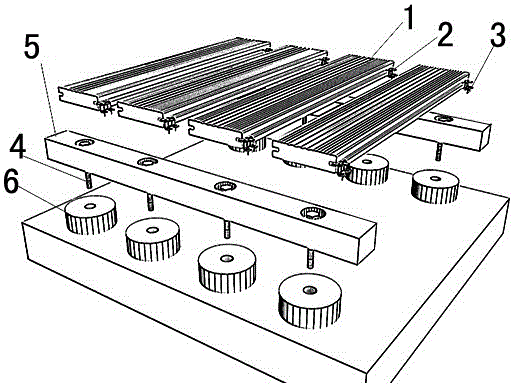

[0024] Example: as figure 1 , figure 2 As shown, a nail-free anti-corrosion wood installation structure includes anti-corrosion wood 1 , connecting fasteners 2 , wooden keels 5 , and ceramsite concrete base 6 .

[0025] The ceramsite concrete base 6 is fixed on the ground, and the wooden keel 5 is installed on the ceramsite concrete base 6 through expansion bolts 4. The firmware is installed on the wooden keel 5. The spacing of expansion bolts 4 is 300mm*500mm; the section size of wooden keel 5 is 40mm*50mm. The two sides of the anti-corrosion wood 1 are respectively provided with grooves, and the connecting fastener 2 includes two sides of the insertion end, one side of the insertion end is inserted into the groove of a piece of anti-corrosion wood 1, and the other side of the insertion end is inserted into the adjacent to the above-mentioned anti-corrosion wood. In the groove of another piece of preservative wood 1.

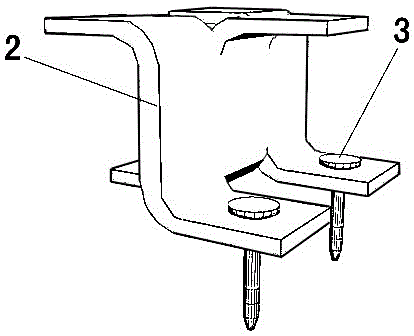

[0026] like image 3 As shown, the connecting faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com