Pre-buried construction method for high-precision foundation bolts

An anchor bolt and high-precision technology, which is applied in the field of steel structure construction engineering, can solve problems that affect the normal installation and commissioning of equipment, require high construction accuracy, and low pre-embedded precision, so as to achieve easy understanding and improve the quality of pre-embedded construction , the effect of high construction precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

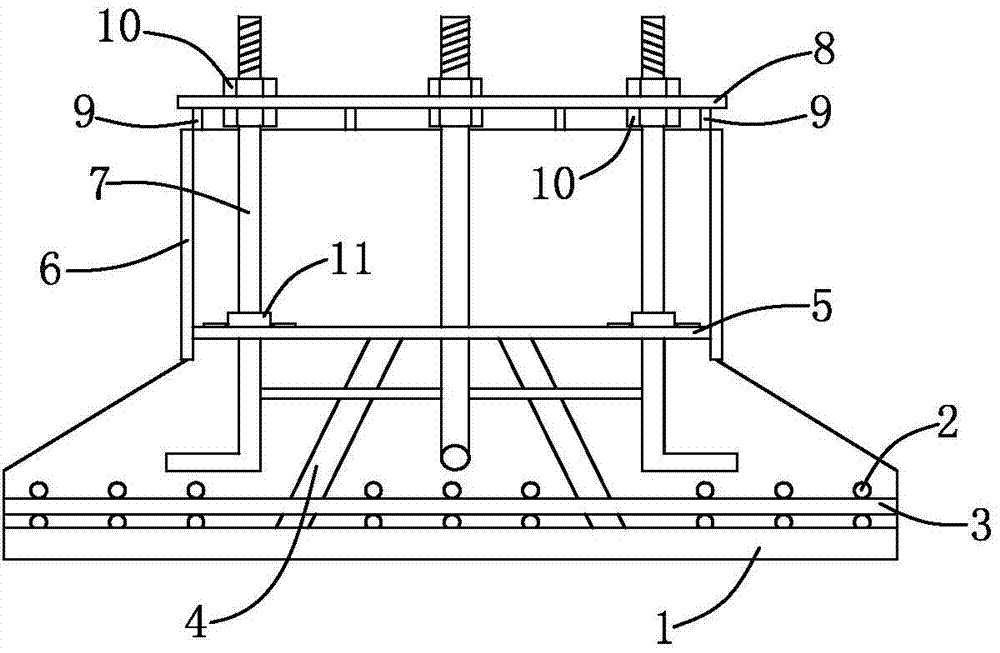

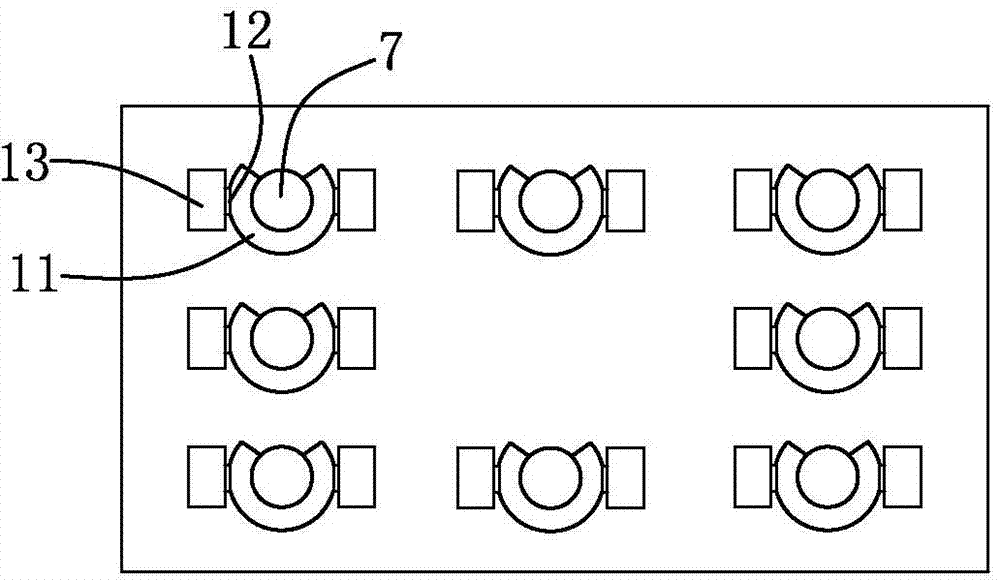

[0031] The high-precision anchor bolt pre-embedded construction method of the present invention, according to the construction drawing of the pre-embedded bolt group, makes corresponding high-precision positioning fixtures for each group of bolt groups arranged in different planes, and uses the high-precision special fixture template to copy the number of bolt groups For the same positioning control board, by adjusting the elevation and vertical height, the pre-embedded anchor bolt group is fully welded and fixed with the Φ12 steel bar head and the reserved steel bar of the cushion layer, and then the elastic clamp is used to further strengthen the anchor bolts to prevent the anchor bolts from The bolts are loosened, which improves the accuracy and protects the anchor bolts. Before concrete pouring, all the bolt groups are placed on the positioning control board, and the control board is fixed with double nuts. The control board is used to control the level and Vertical load, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com