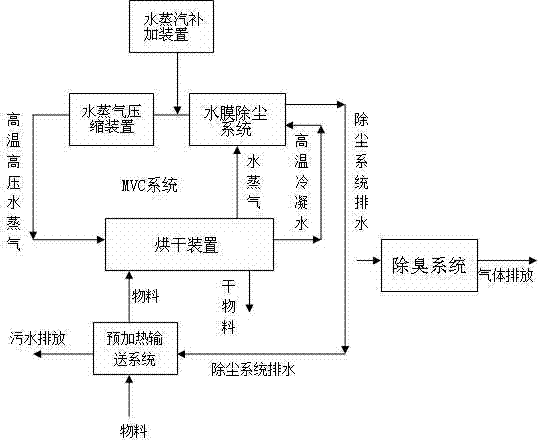

A sludge mvc evaporation drying system and method for drying sludge

A drying system and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of ineffective utilization and loss, and achieve stable and efficient operation, saving use costs, and reducing treatment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A leather factory in Yangzhou produces about 12 tons of wet sludge per day. In the past, the traditional sludge steam drying technology was used for sludge drying treatment. The water enters the wastewater treatment tank for retreatment; its direct operating costs are as follows: 1) Steam cost: Generally, about 0.8 tons of steam is needed to dry 1 ton of wet sludge, and the unit price of steam is 240 yuan / ton, so the steam cost is E 1 =0.8*240=192 yuan / ton; 2) Electricity fee: 0.5 tons of wet sludge per hour, sludge lifting device operating power 1.5kw, dryer stirring power 15kw, water film dust removal, comprehensive oxidation treatment device, induced draft fan The operating power is 8kw, the total operation is 24.5kw, and the electricity fee is 0.8 yuan / ton, then the electricity fee is E 2 =24.5*0.8 / 0.5=39.2 yuan / ton. Total E=E 1 +E 2 =231.2 yuan / ton.

[0028] Later, the sludge drying technology of the present invention was adopted for technical transformation, a...

Embodiment 2

[0046] A fertilizer factory in Nanjing produces about 30 tons of wet sludge per day. In the past, the traditional sludge steam drying technology was used for sludge drying treatment. The water enters the wastewater treatment tank for re-treatment; its direct operating costs are as follows: 1) Steam cost Generally, about 0.85 tons of steam is needed to dry 1 ton of wet sludge, and the unit price of steam is 260 yuan / ton, so the steam cost is E 1 =0.85*260=221 yuan / ton; 2) The electricity fee is 1.25 tons of wet sludge per hour, the operating power of the sludge lifting device is 1.5kw, the stirring power of the dryer is 37.5kw, water film dust removal, comprehensive oxidation treatment device, induced draft fan The operating power is 12kw, the total operation is 51kw, and the electricity fee is calculated at 0.8 yuan / ton, then the electricity fee is E 2 =51*0.8 / 1.25=32.6 yuan / ton. Total E=E 1 +E 2 =253.6 yuan / ton.

[0047] Using the MVC sludge drying technology of the prese...

Embodiment 3

[0064] A feed factory in Nanjing produces about 23 tons of wet sludge per day. Previously, the sludge steam drying technology was used to dry the sludge. The water vapor discharged from the dryer was discharged through the exhaust gas comprehensive oxidation and purification device after being dedusted by the water film, and the dedusted water entered The waste water treatment tank is re-treated; its direct operating costs are as follows: 1), steam cost Generally, drying 1 ton of wet sludge requires about 0.6 tons of steam, and the unit price of steam is 260 yuan / ton, so the steam cost is E1=0.6*260=156 Yuan / ton; 2) The electricity fee is 0.6 tons of wet sludge per hour, the operating power of the sludge lifting device is 1.5kw, the stirring power of the dryer is 15kw, the operating power of water film dust removal, comprehensive oxidation treatment device, and induced draft fan is 8kw, and the total operation is 24.5 kw, the electricity fee is calculated at 0.8 yuan / ton, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com