Preparation method for synthetizing three-dimensional stannous sulfide micro-flowers through complexing agent with aid of quaternary ammonium salt

A technology of stannous sulfide and quaternary ammonium salt, which is applied in the direction of chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problems of many reaction steps, environmental pollution and complexity of waste liquid, and achieve low cost, simple preparation process, The effect of uniform size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

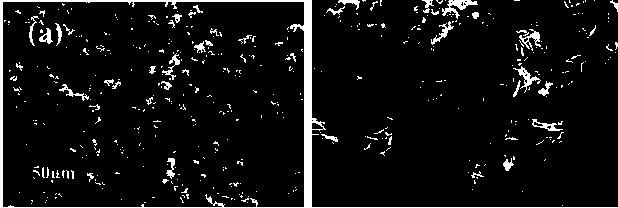

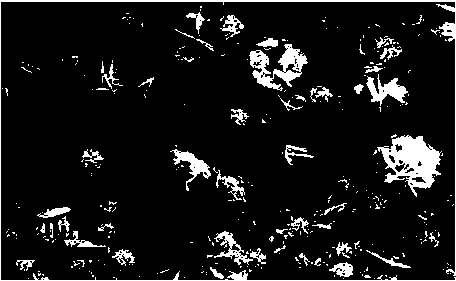

[0031] Dissolve 1mmol of tin tetrachloride in 10ml of deionized water to form solution A, dissolve 4mmol of sodium sulfide in 20ml of deionized water to form solution B; then add solution B dropwise to solution A to form a yellow precipitate, continue to drop Addition, the yellow precipitate gradually dissolved, and finally formed a transparent solution. Then 5mmol of tetrabutylammonium bromide (TBAB) and 4mmol of thiourea were added, and the final solution was transferred to a 50ml stainless steel reactor lined with polytetrafluoroethylene. Place it in a dry box, and conduct a hydrothermal reaction at 180° C. for 6 hours. Then it was naturally cooled to room temperature, and the obtained precipitate was rinsed three times with deionized water and absolute ethanol, separated by centrifugation, and dried in a vacuum oven at 60° C. for 12 hours. The hydrothermally obtained sample was placed in a tube furnace and calcined at 500° C. for 3 hours under the protection of nitrogen t...

Embodiment 2

[0033] Dissolve 1mmol of tin tetrachloride in 10ml of deionized water to form solution A, dissolve 4mmol of sodium sulfide in 20ml of deionized water to form solution B; then add solution B dropwise to solution A to form a yellow precipitate, continue to drop Addition, the yellow precipitate gradually dissolved, and finally formed a transparent solution. Then 3mmol of tetrabutylammonium bromide (TBAB) and 4mmol of thiourea were added, and the final solution was transferred to a 50ml stainless steel reactor lined with polytetrafluoroethylene. Put it in a dry box, and conduct a hydrothermal reaction at 170° C. for 4 hours. Then it was naturally cooled to room temperature, and the obtained precipitate was rinsed three times with deionized water and absolute ethanol, separated by centrifugation, and dried in a vacuum oven at 50° C. for 14 hours. The hydrothermally obtained samples were placed in a tube furnace and calcined at 400°C for 2 hours under the protection of nitrogen to ...

Embodiment 3

[0035] Dissolve 0.5mmol of tin tetrachloride in 10ml of deionized water to form solution A, dissolve 2mmol of sodium sulfide in 20ml of deionized water to form solution B; then add solution B dropwise to solution A to form a yellow precipitate, continue Dropwise, the yellow precipitate gradually dissolved and finally formed a transparent solution. Then 2 mmol of tetrabutylammonium bromide (TBAB) and 2 mmol of thiourea were added, and then the final solution was transferred to a 50 ml stainless steel reactor lined with polytetrafluoroethylene. Put it in a dry box, and conduct a hydrothermal reaction at 180° C. for 8 hours. Then it was naturally cooled to room temperature, and the obtained precipitate was rinsed three times with deionized water and absolute ethanol, separated by centrifugation, and dried in a vacuum oven at 70° C. for 10 hours. The hydrothermally obtained sample was placed in a tube furnace and calcined at 300° C. for 4 hours under the protection of nitrogen to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com