Roller bed bearing block positioning device and manufacturing and application methods thereof

A technology of positioning device and bearing seat, which is applied in the direction of rollers, transportation and packaging, conveyor objects, etc., can solve the problems of large processing volume, unadjustable assembly, high manufacturing cost, etc., and achieve the effect of simple processing and no slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

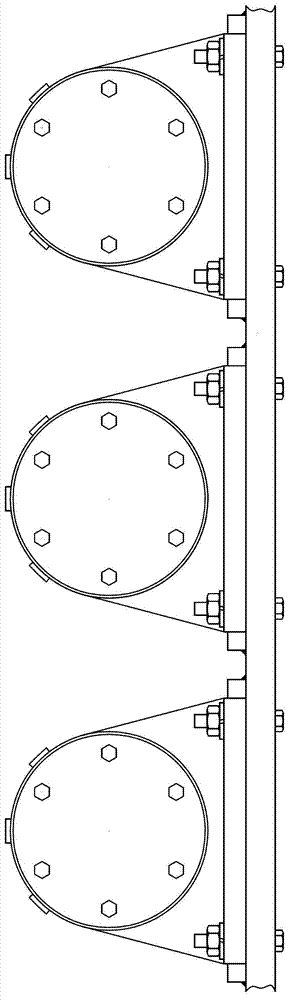

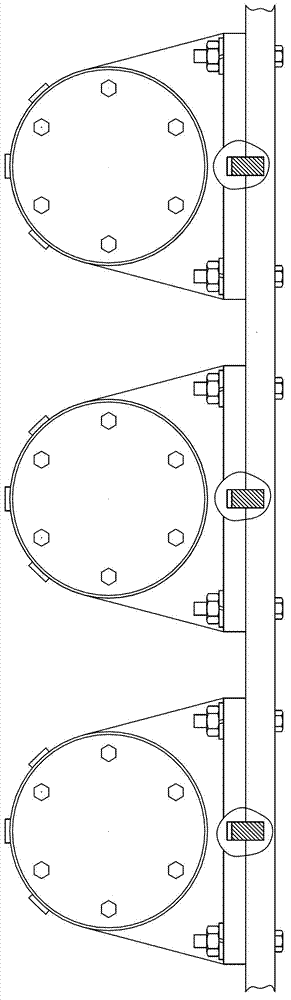

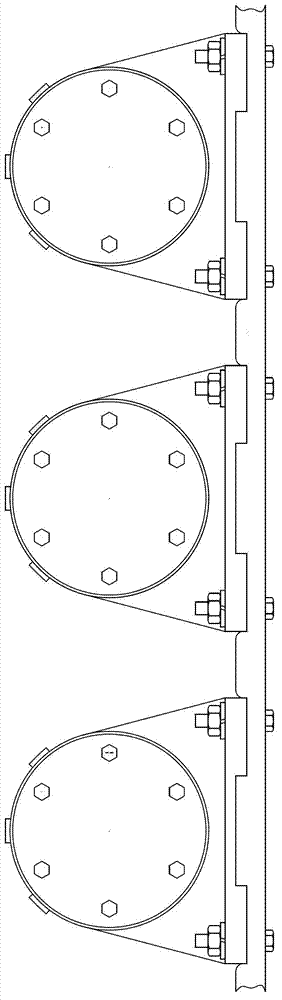

[0020] as attached Figure 4 , 5 As shown, the positioning steel plate (1) is in the shape of a cuboid, located between the bases of two adjacent bearing seats (2), and the two lateral sides of the positioning steel plate (1) are respectively attached to the bases of the adjacent bearing seats (2). There are two circular through-holes (4) in the center of the upper surface of the positioning steel plate (1). The shape of the through-holes (4) is preferably waist-shaped, because among the through-holes (4) with the same area, the waist-shaped through-holes (4) Longest weld seam for greater shear resistance. A circle of weld seam (5) is welded between the through hole (4) and the contact periphery of the base of the roller table frame (3), and the weld seam (5) fixes the positioning steel plate (1) on the base of the roller table frame (3) .

[0021] The thickness of the positioning steel plate (1) is 0.8 to 1.2 times the thickness of the base of the bearing housing (2). If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com