Semi-submersible oil storage platform system for well drilling

A semi-submersible and drilling technology, applied to floating buildings and other directions, can solve the problems of low payload, high construction difficulty and cost, and poor mobility, so as to reduce the dependence on dynamic positioning, improve utilization rate and economy, and improve Effects on Stability and Sports Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

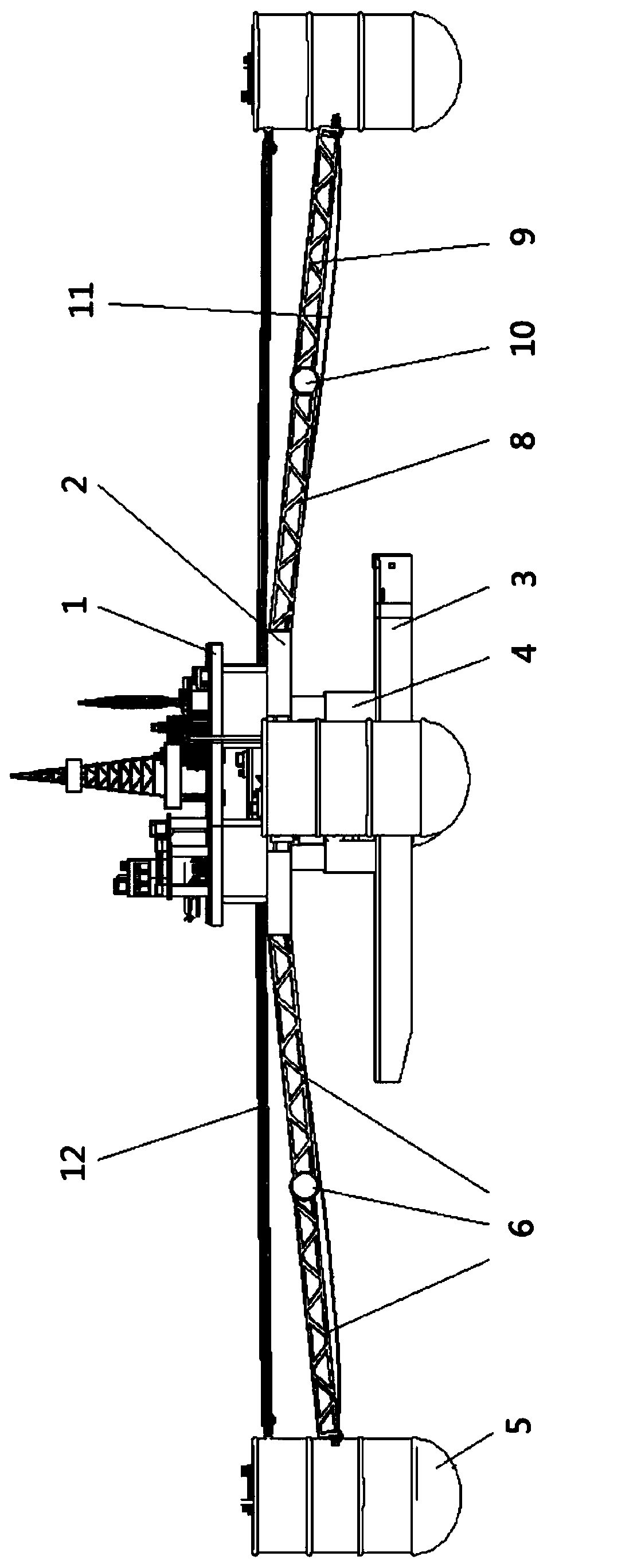

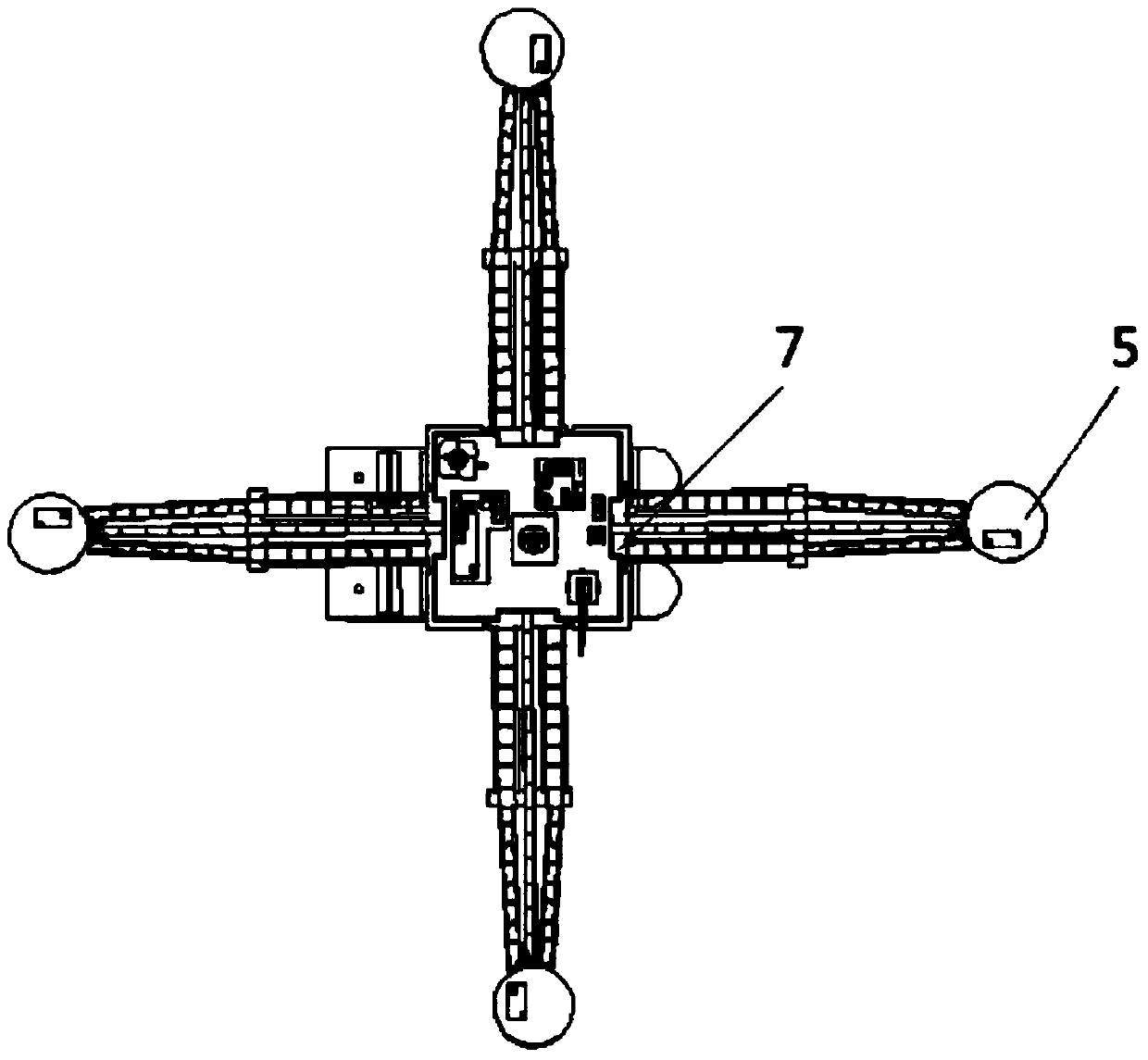

[0028] Such as figure 1 — Figure 4 Shown: Example 1

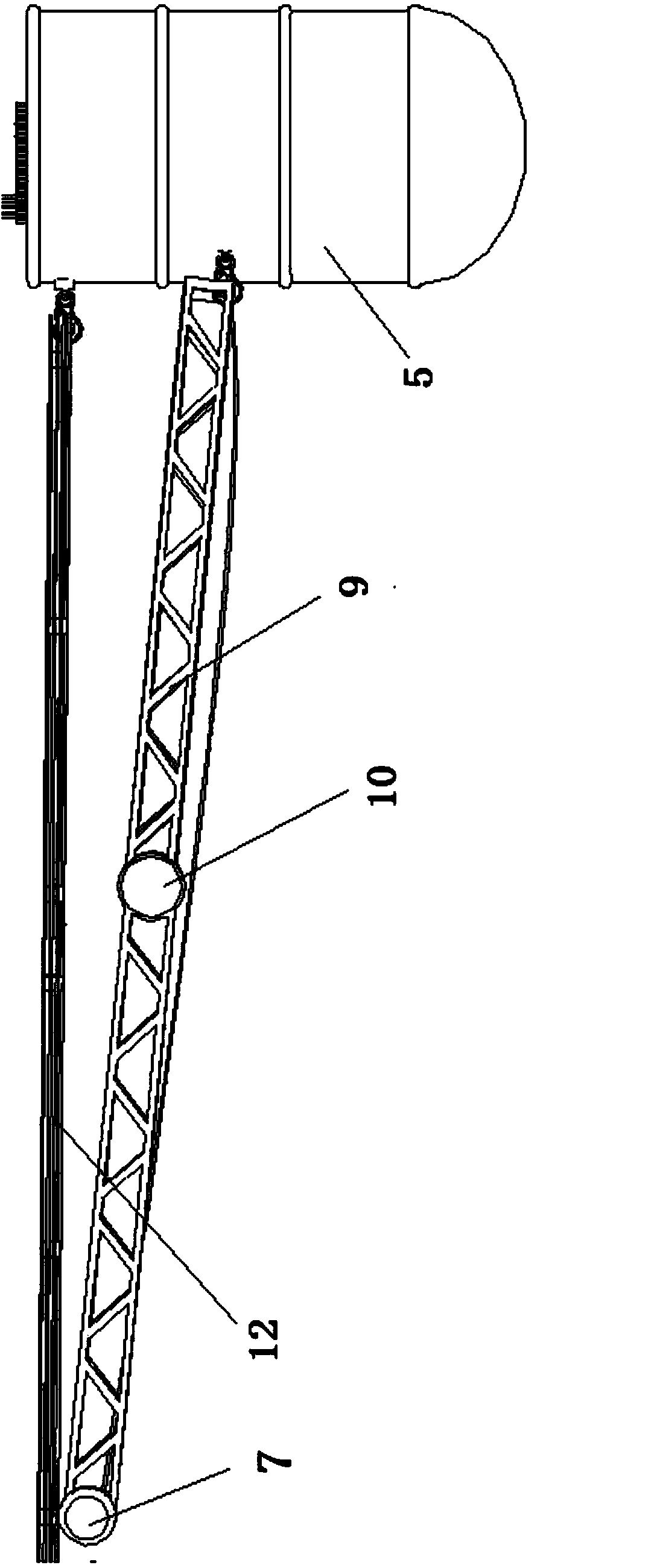

[0029] A new semi-submersible drilling and oil storage platform system mainly includes a semi-submersible main platform, four floating sub-platforms, connecting arms and trestle structures connecting them. The main platform is mainly composed of a deck 1, a second deck 2, buoys 3, and columns 4. The four floating sub-platforms 5 are respectively located on the port side, starboard side, bow, and stern of the main platform. Each floating sub-platform is connected to the main platform through a truss connecting arm 6. The connecting arm 6 is perpendicular to the side of the middle part.

[0030] Each truss c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com