Device for producing fullerene efficiently with arc process

A production device and fullerene technology, applied in the field of high-efficiency arc fullerene production devices, can solve problems such as low production capacity and efficiency, unreachable industrial production, and inability of scientific research devices to meet requirements, so as to achieve high-efficiency production, output and efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

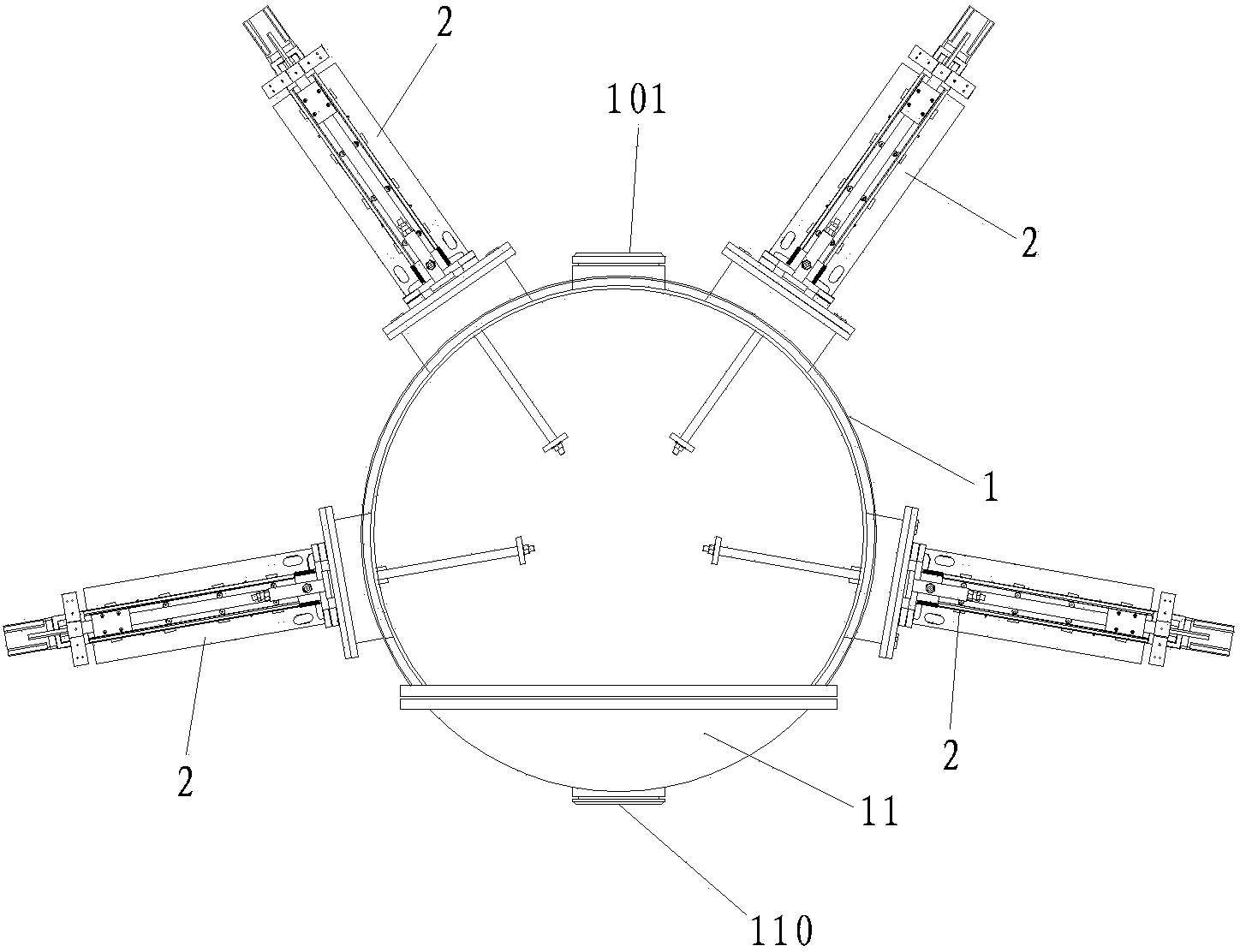

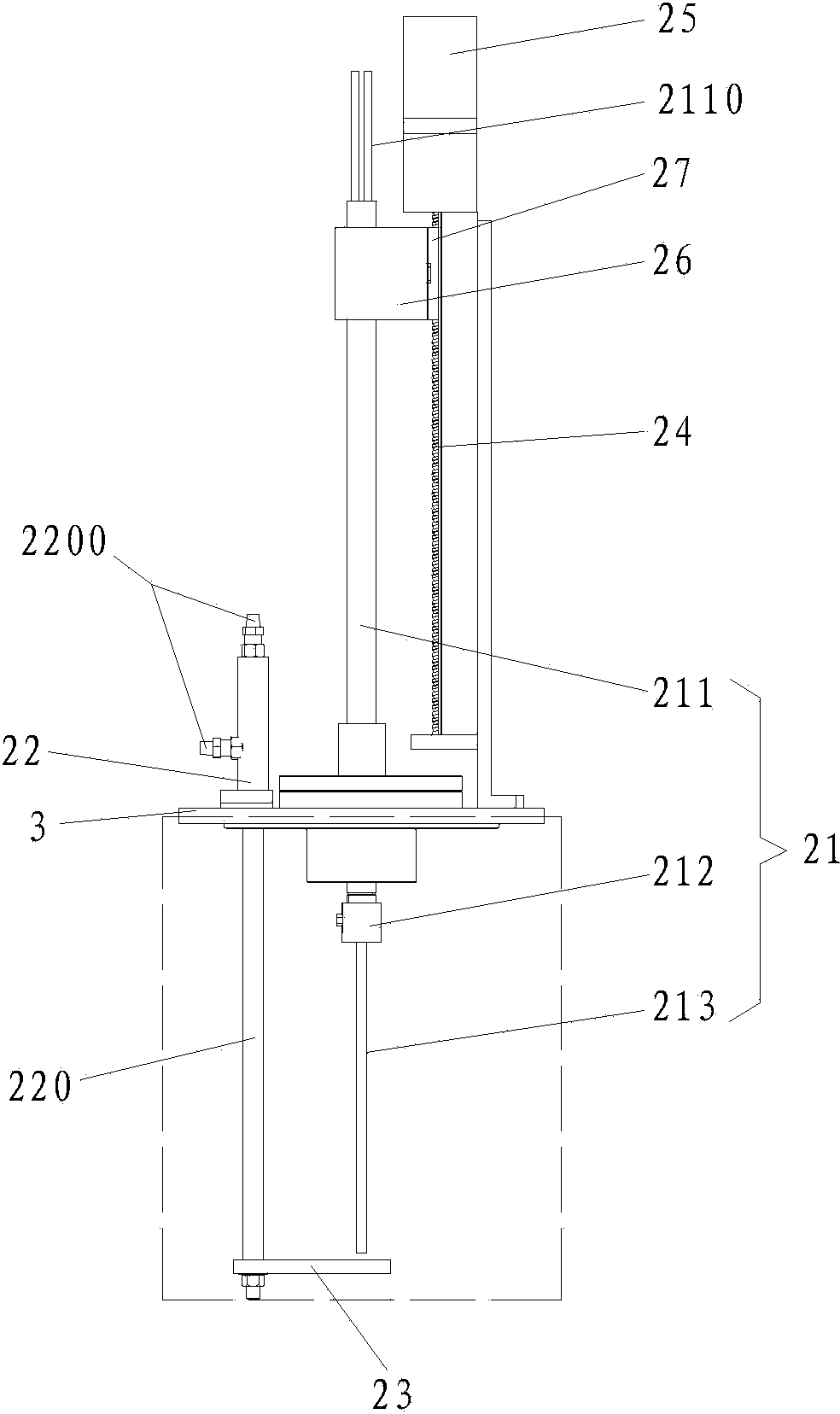

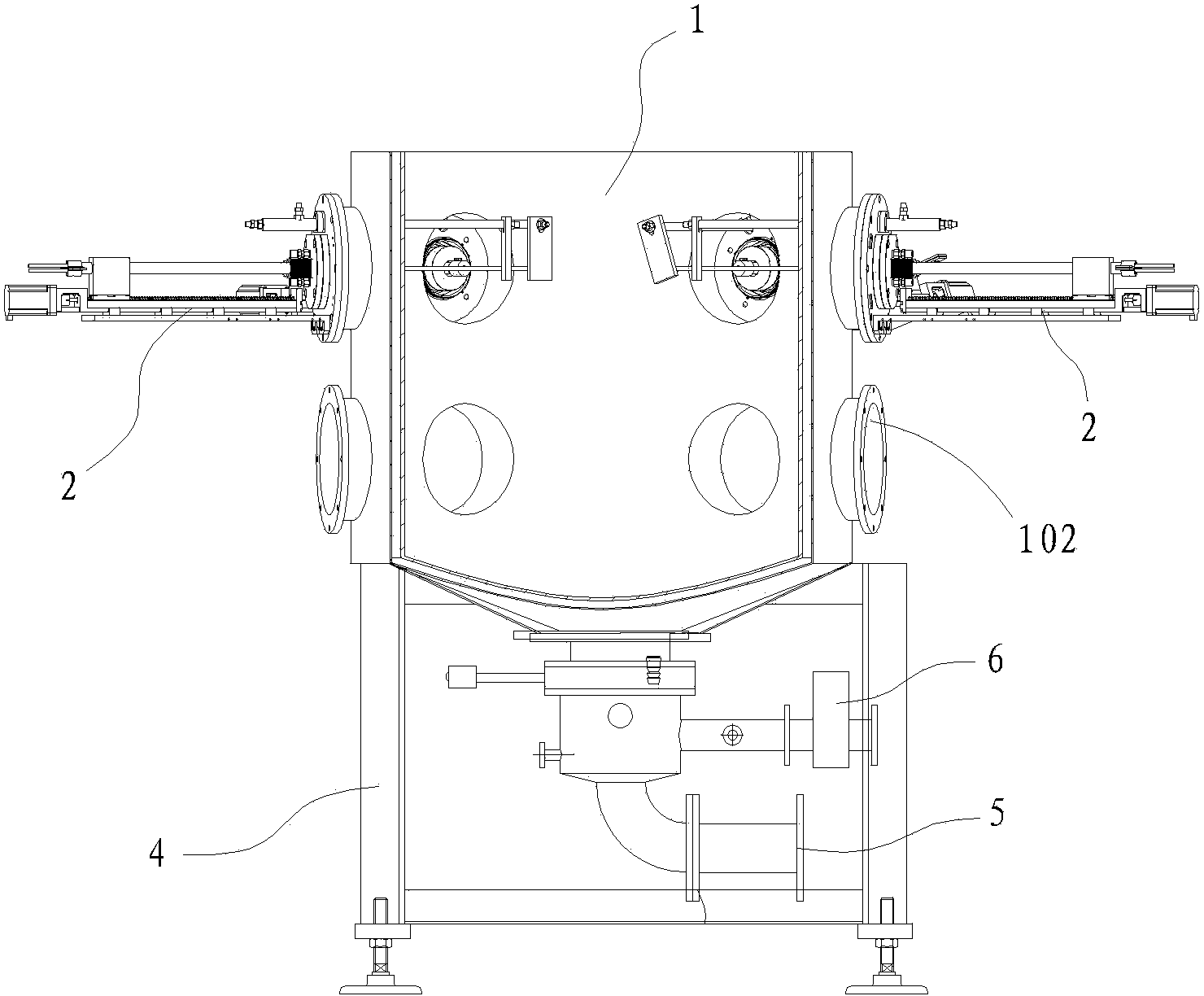

[0022] Example: see Figure 1 to Figure 3 , a high-efficiency fullerene production device by arc method, comprising a vacuum furnace 1, and more than one independent arc source 2 is installed in the vacuum furnace 1, each arc source includes an anode 21, a cathode 22 and a cathode trigger body 23, said The anode 21, the cathode 22 and the cathode trigger 23 form a circular guide circuit, and the anode 21 and the cathode trigger 23 of each arc source 2 can simultaneously generate an arc to produce a mixture containing fullerene. The vacuum furnace 1 is equipped with arc sources 2 layer by layer from top to bottom, and the number of arc sources 2 on each layer is at least one and distributed along the circumference of the vacuum furnace. figure 1 Four arc sources are installed in the vacuum furnace on this layer, and each arc source is fixed at the corresponding interface of the vacuum furnace through the furnace body mounting plate 3 or the flange. image 3 A flange 102 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com