Method for preparing low-temperature concentrated coconut milk

A technology of low-temperature concentration and coconut milk, which is applied in food preparation, function of food ingredients, food science, etc., to achieve the effect of simple operation, large processing capacity, and reduced oil-water stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

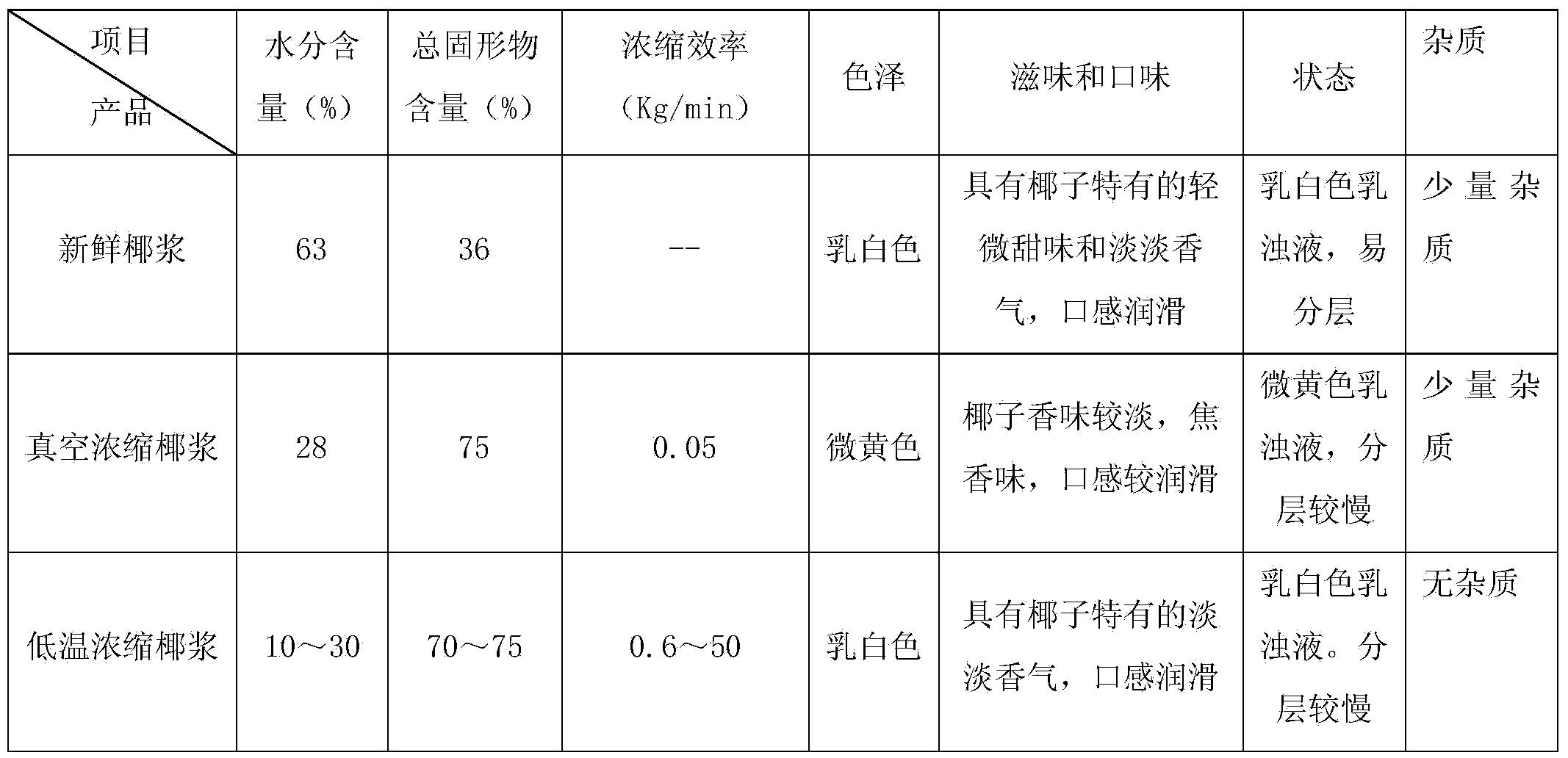

Embodiment 1

[0032] (1) Take an 18-month-old coconut, remove the shell, seed coat and coconut water, and then grind 90Kg of fresh coconut meat in a shredded machine. Put the shredded coconut meat into a mesh bag, put it into a press barrel, and then put the press barrel into a milking machine to squeeze to obtain 30Kg of coconut milk. The coconut milk is filtered with a 100-mesh screen for concentration.

[0033] (2) Take 20Kg of the prepared coconut milk and place it in the hopper of a disc centrifuge, keep the centrifugal pressure at 20bar, the speed at 10000r / min, centrifuge for 30min, and keep the temperature at 25°C, the upper layer obtained after centrifugation The solution is low temperature concentrated coconut milk 6Kg. The water content of the concentrated coconut milk is 25%, the total solid content is 71%, and the concentration efficiency is 0.67Kg / min.

Embodiment 2

[0035] (1) Take an 18-month-old coconut, remove the shell, seed coat and coconut water, and grind 120Kg of fresh coconut meat in a wedge-template grinder and a roller press. Put the shredded coconut meat into a mesh bag, put it into a press barrel, and then put the press barrel into a milking machine to squeeze to obtain 50Kg of coconut milk. The coconut milk is filtered with a 100-mesh screen for concentration.

[0036] (2) Take 40Kg of the prepared coconut milk, put it in the whey separator, keep the centrifugal speed at 3000r / min, the whey outlet pressure at 35bar, centrifuge for 5min, keep the temperature at 25°C, and the demulsification obtained after centrifugation Clear solution is concentrated coconut milk 16Kg. The water content of this concentrated coconut milk is 30%, and total solid content is 72%, and concentration efficiency is 8Kg / min.

Embodiment 3

[0038] (1) Take an 18-month-old coconut, remove the shell, seed coat and coconut water, and then grind 240Kg of fresh coconut meat in a screw press. Put the shredded coconut meat into a mesh bag, put it into a press barrel, and then put the press barrel into a milking machine to squeeze to obtain 64Kg of coconut milk. The coconut milk is filtered with a 100-mesh screen for concentration.

[0039] (2) Take 50Kg of coconut milk that has been prepared, put it in a decanter centrifuge, keep the speed at 4000r / min, the differential speed is 10r / min, the centrifugation time is 1min, and the temperature is kept at 25°C. After centrifugation, the dehydrated The solution is concentrated coconut milk 14Kg. The water content of this concentrated coconut milk is 26%, and total solid content is 70%, and concentration efficiency is 50Kg / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com