Method and device for biface chip tin soldering glue preparation

A chip and solder technology, applied in the field of chip solder glue preparation method and device, can solve the problems of uneven size of solder joints, waste of raw materials, low qualification rate, etc., achieve uniform size of solder joints, full utilization, improve production efficiency and The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

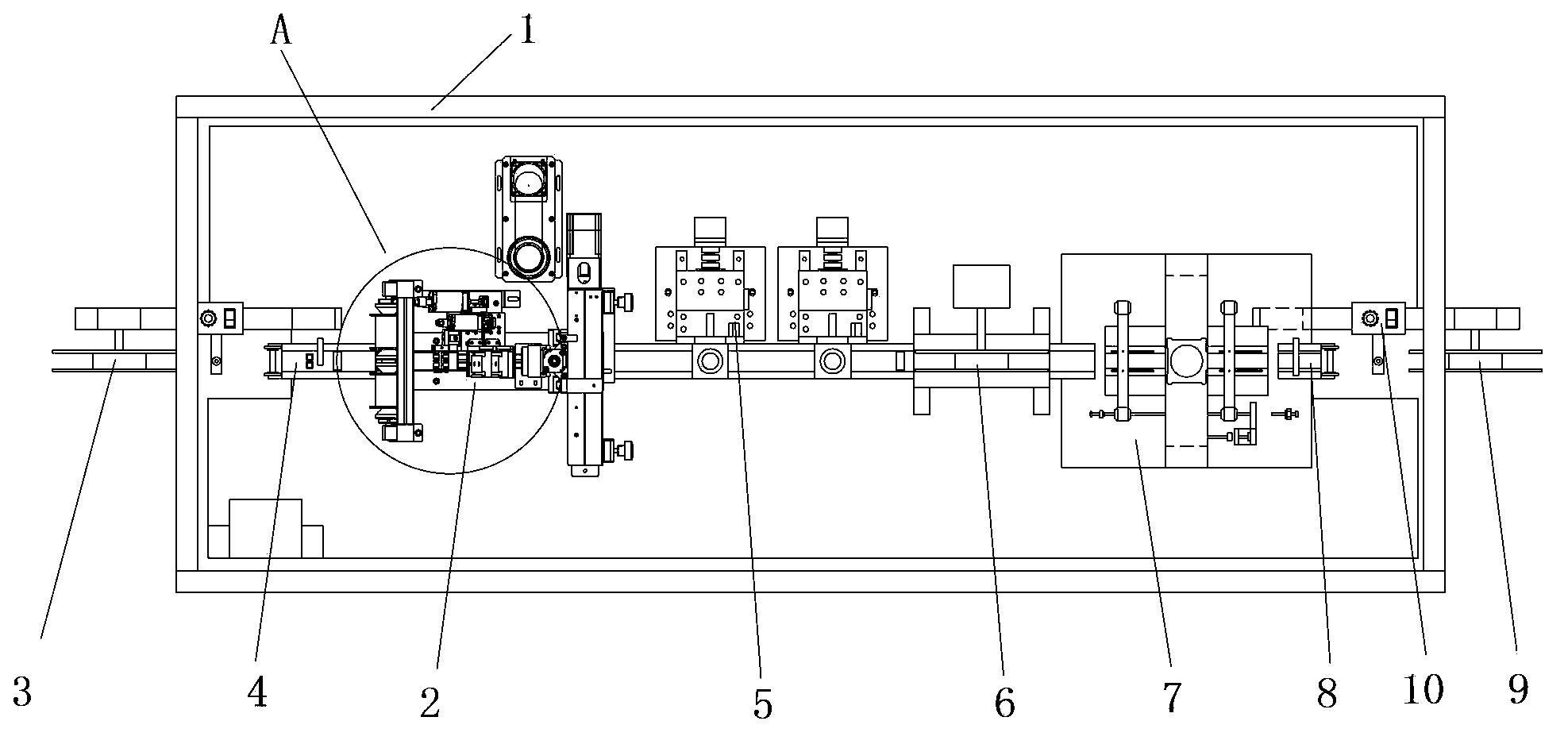

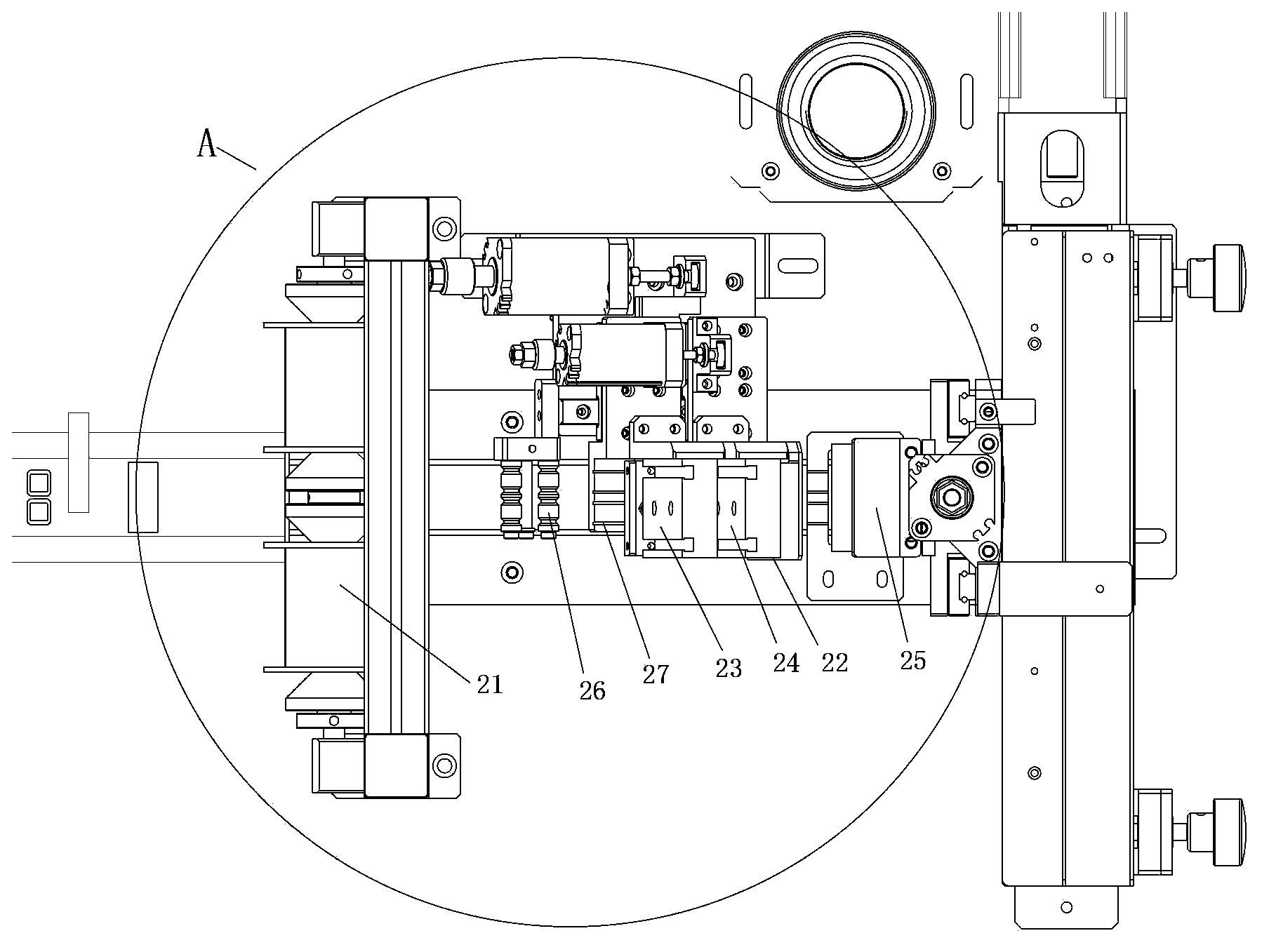

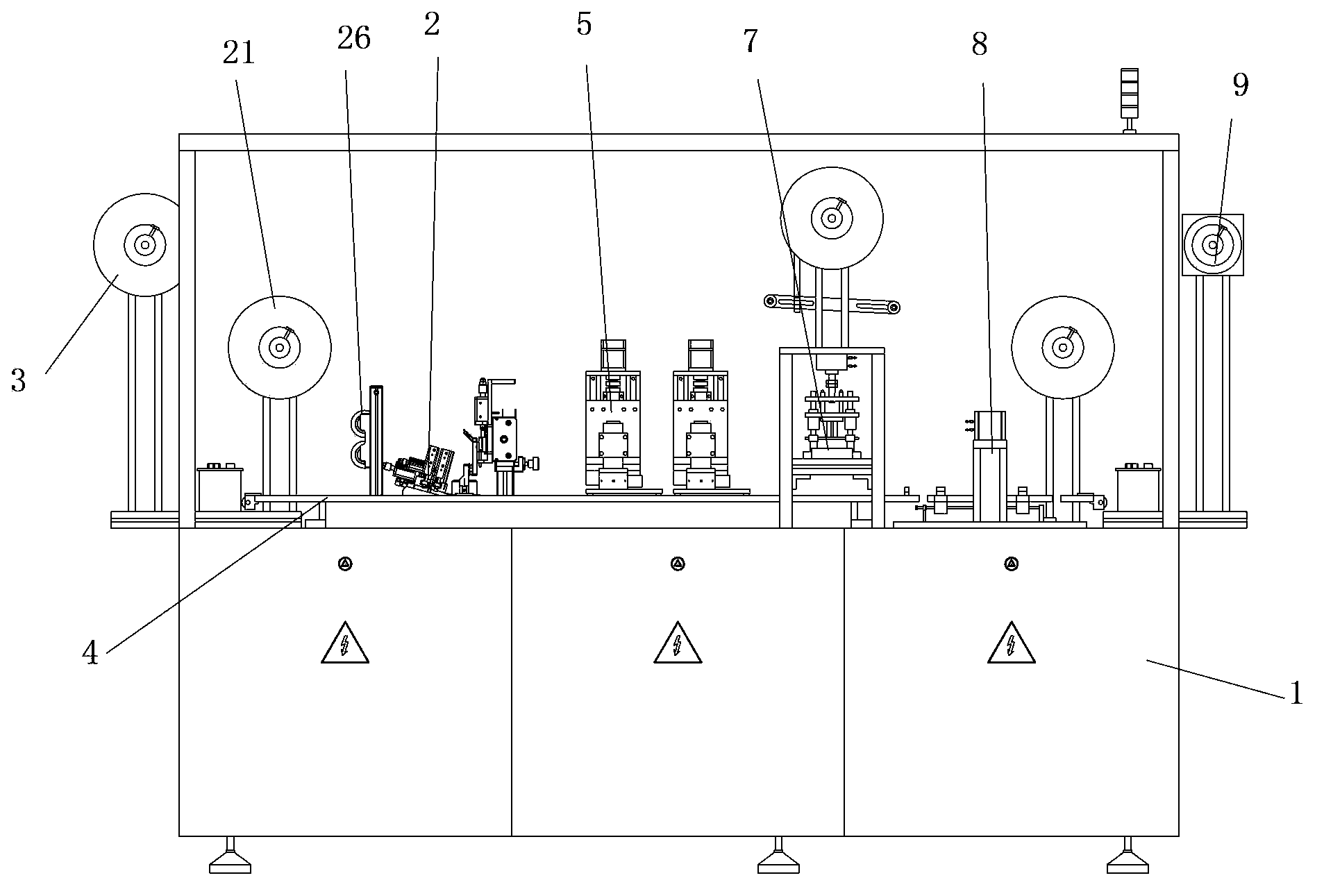

[0054] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0055] In the prior art, when the chip is soldered, the length of the tin wire sent to the predetermined soldering point of the chip is uneven, which often leads to defects such as uneven soldering point size, waste of raw materials, low efficiency, and low pass rate. The present invention aims at the above defects, The soldering method and device are restructured. The main technical means of the present invention are: first use the first crimping and feeding device to draw the tin wire, and then use the second crimping and feeding device to pull the tin wire to the predetermined soldering point of the chip, The moving distance of both pulling the tin wire is equal to the length of the tin wire required when soldering on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com