A special electron gun for electron beam bombardment furnace

A technology of electron beam bombardment and electron gun, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of reducing the life of the cathode, decreasing the beam flux rate, and affecting the life of the electron gun, so as to achieve the effect of reducing life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

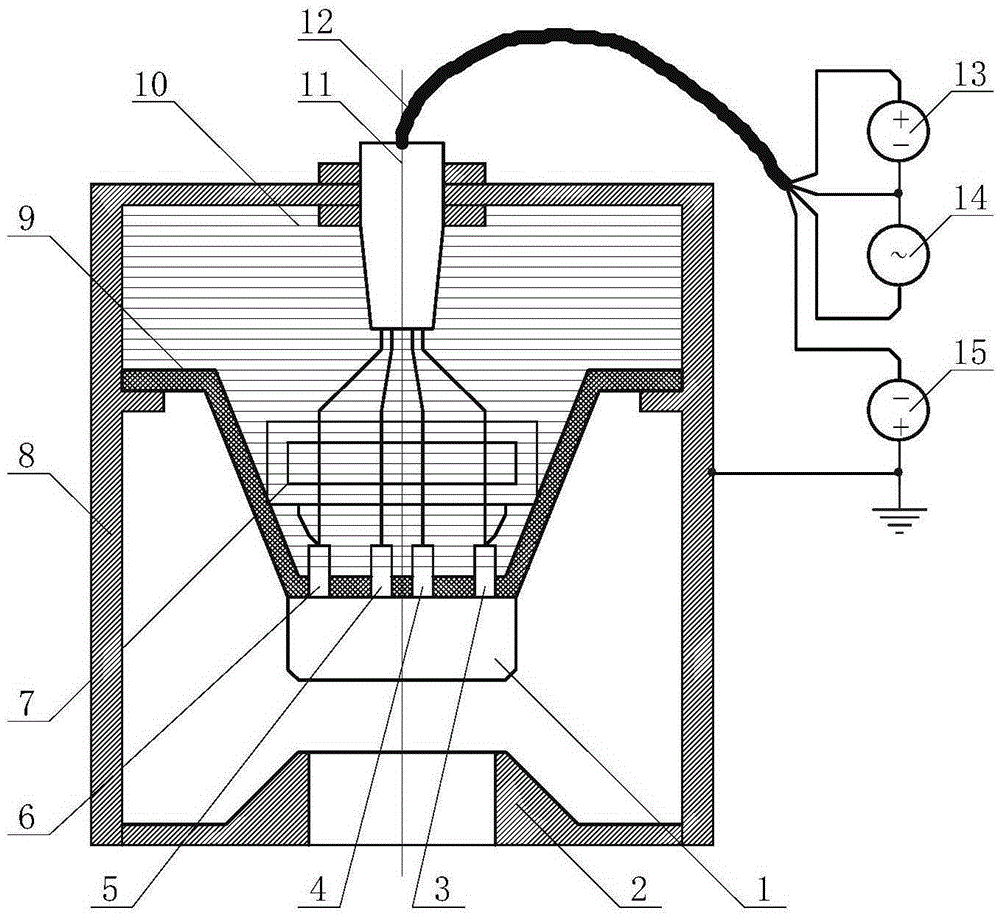

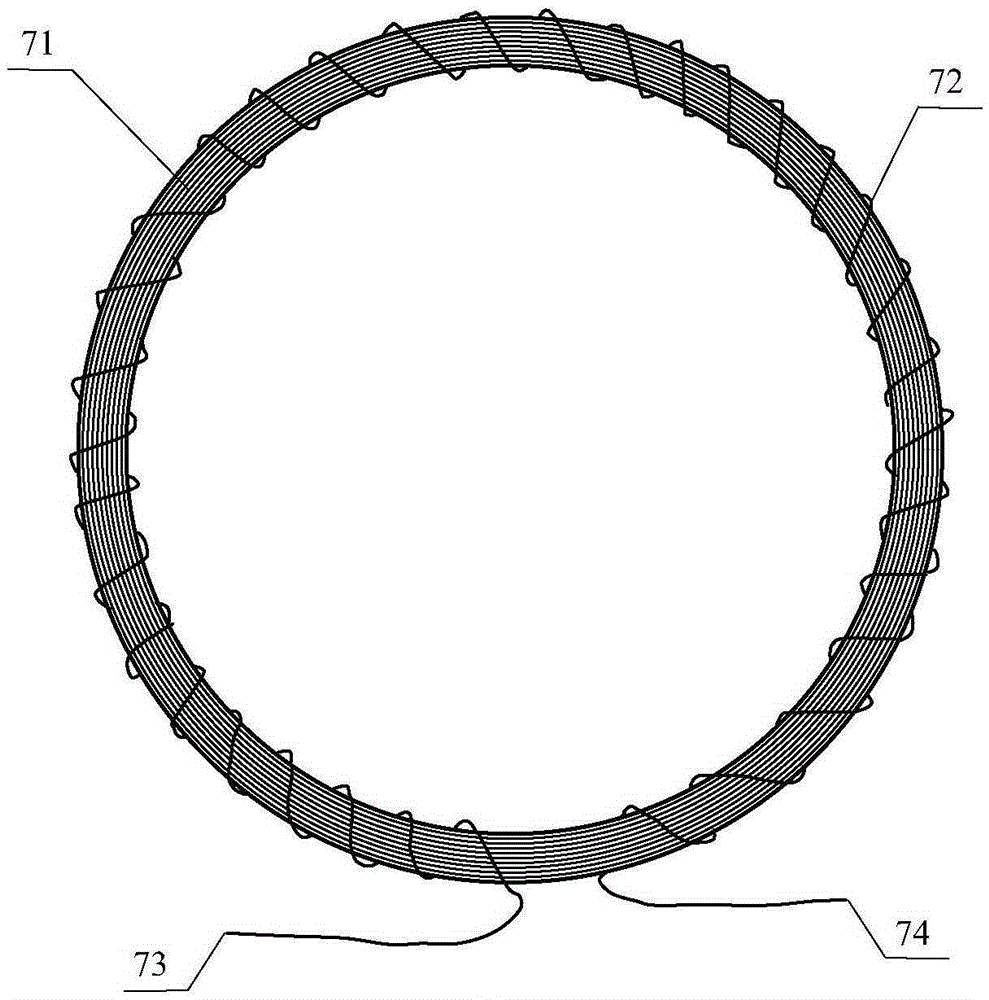

[0011] A special electron gun for electron beam bombardment furnace, such as figure 1 As shown, it mainly consists of an electron gun housing 8, and a filament, a cathode and a focusing electrode assembly 1, an anode 2, a focusing electrode 3, a filament head end electrode 4, a filament end electrode 5, and a cathode electrode arranged in the electron gun housing 8. 6. Insulation assembly 9, insulation cooling oil 10 and high voltage cable outlet 11. The first electrode 4 of the filament and the end electrode 5 of the filament are led out through the high-voltage cable lead-out head 11 fixed on the electron gun shell 8 and connected to the two poles of the filament power supply 14 through the high-voltage cable 12 respectively. The focusing electrode 3 and the cathode electrode 6 are also led out through the above-mentioned high-voltage cable lead-out head 11 and connected to the negative pole of the accelerating power supply 15 and the positive pole of the bombardment power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com