A calibration method for optical constants of metal and semiconductor thin film materials

A technology of optical constants and calibration methods, which is applied in the direction of color/spectral characteristic measurement, measuring device, scattering characteristic measurement, etc. It can solve the problems of inability to judge the correct solution and the low precision of the solution parameter solution process, so as to eliminate errors and be widely applicable The effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Calibration of optical constants of electron beam evaporated Cr film

[0031] 1. According to the method mentioned above, the optical constants of Cr thin films evaporated by electron beams were calibrated. We prepared thin film samples with an estimated physical thickness of 15-100 nm, and deposited them on BK7 optical glass at a deposition rate of 0.2 nm / s.

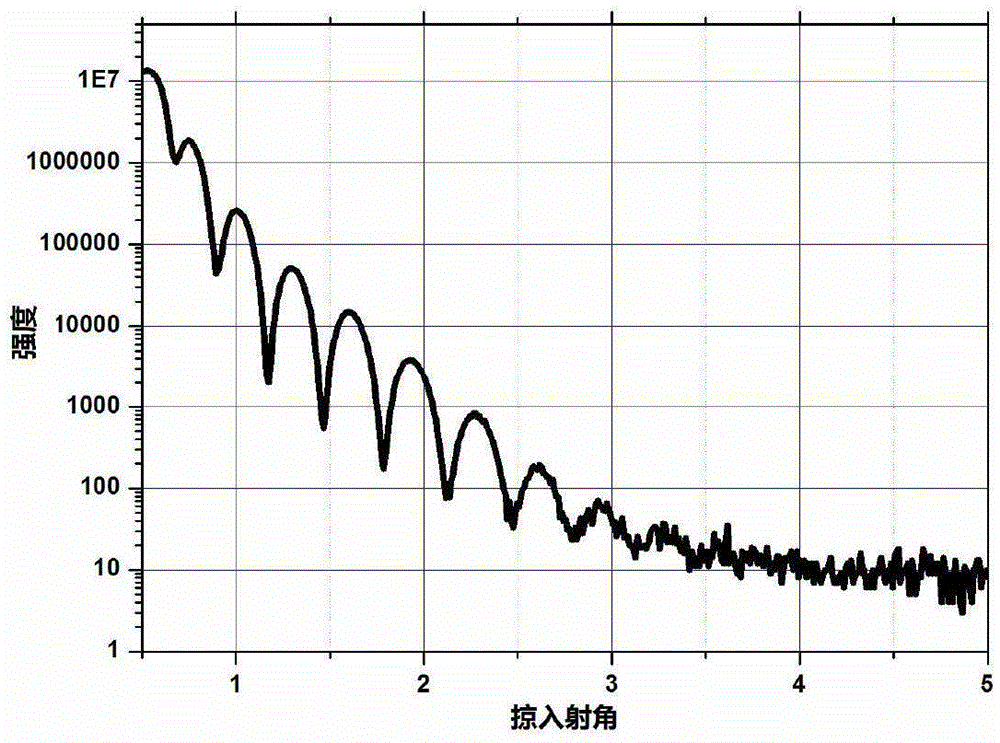

[0032] 2. The X-ray small-angle reflectance curve was tested for the film sample, and the X-ray with a wavelength of 0.154nm was selected for testing. Test curve such as figure 2 shown.

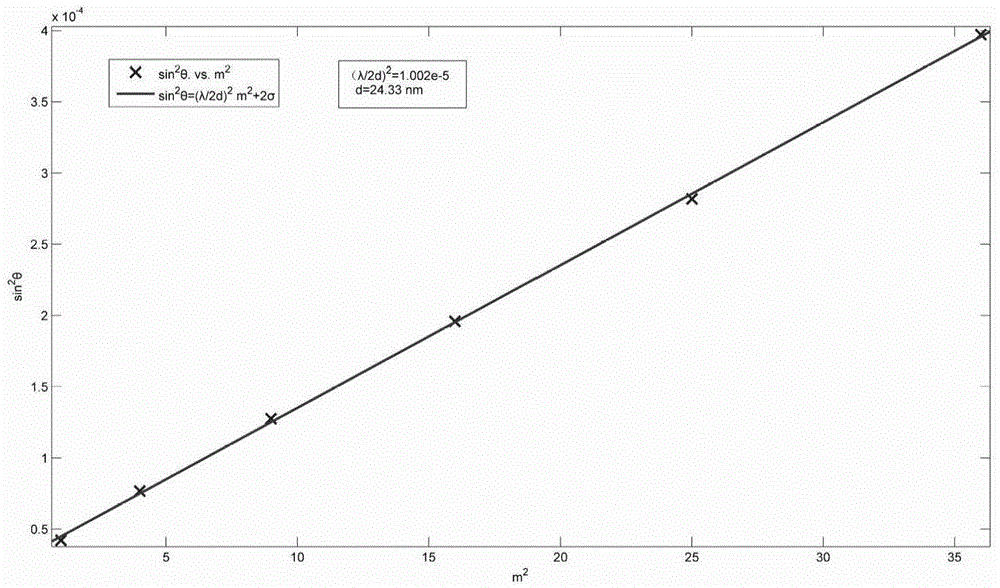

[0033] 3. According to the modified Bragg equation sin 2 θ m =(λ / 2d) 2 m 2 +2δ, λ=0.154nm Statistical data are shown in Table 1, and then do linear regression analysis, such as image 3 As shown, the thickness of the obtained film is 24.32 nm.

[0034] 4. The transmittance and reflectance values of the test film at 0 degrees are shown in Table 2, and the test wavelength is from 415nm to 800nm.

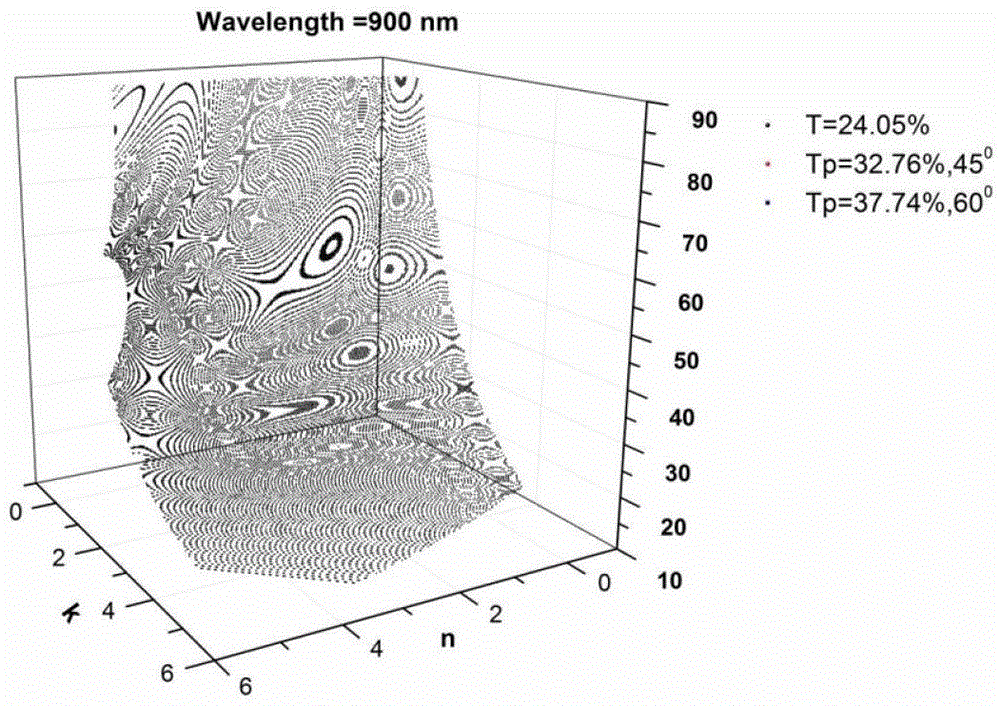

[0035] 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com