Pneumatic gate valve

A technology of gates and gates, applied in the field of pneumatic gates, which can solve problems such as premature reimbursement, improper closing of gates, and shortened life of pneumatic gates, so as to reduce energy consumption, reduce power generation costs, and reduce maintenance difficulty and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

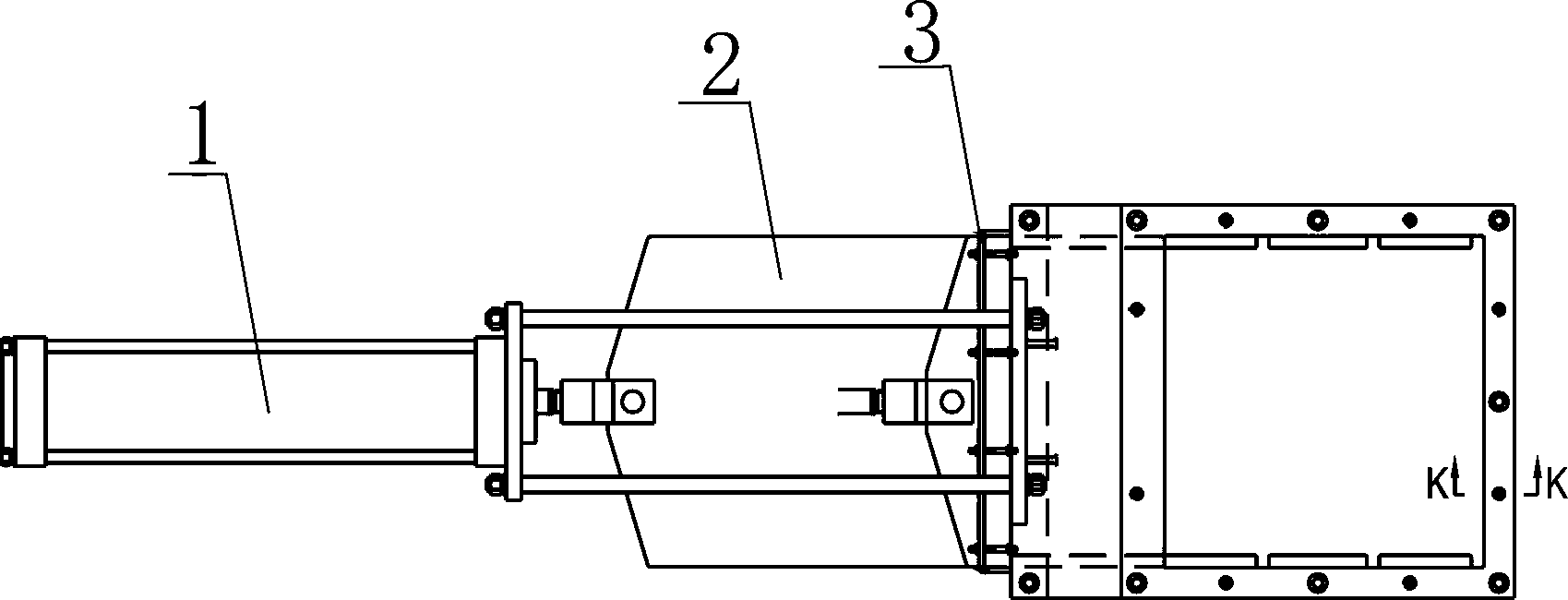

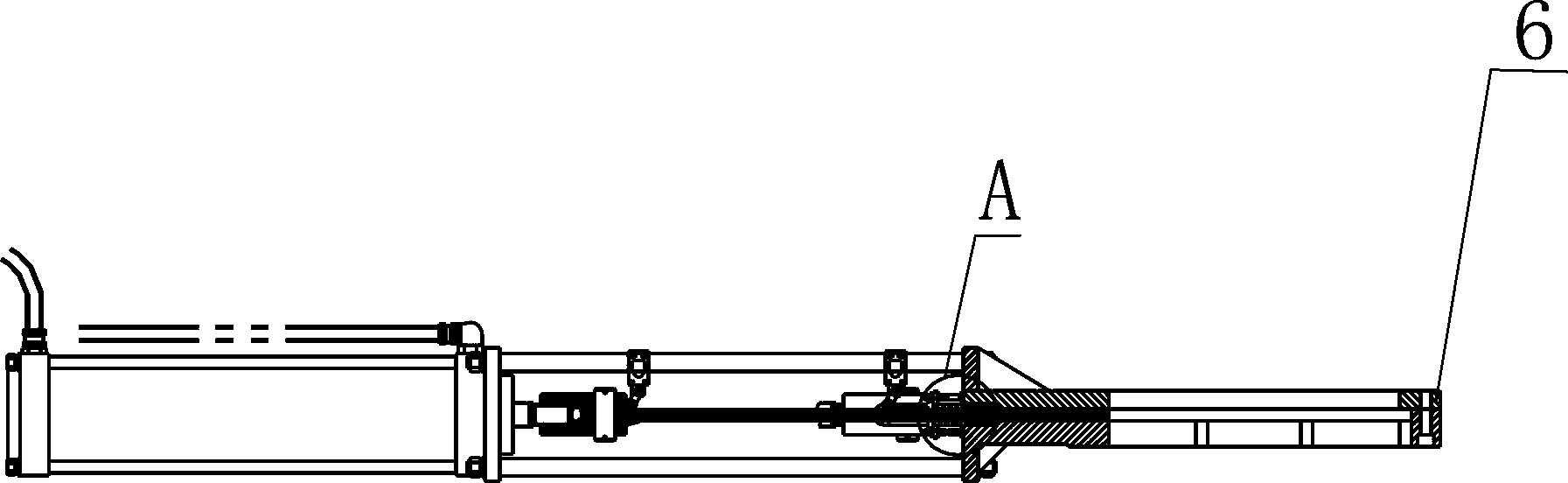

[0016] Such as Figure 1~Figure 4 As shown, a pneumatic gate includes a cylinder group 1 and a gate plate 2. The housing of the pneumatic gate includes: an upper half seat 6 and a lower half seat 4, the upper half seat 6 is connected with the lower half seat 4, and the upper half seat 6 is connected with the lower half seat 4. The end of the housing formed by the half seat 6 and the lower half seat 4 is square, and the upper half seat 6 and the lower half seat 4 are respectively connected to the sealing gland 3 by studs 8 .

[0017] The push-pull force generated by the cylinder group 1 makes the gate plate 2 move back and forth to realize the closing and opening of the pneumatic gate.

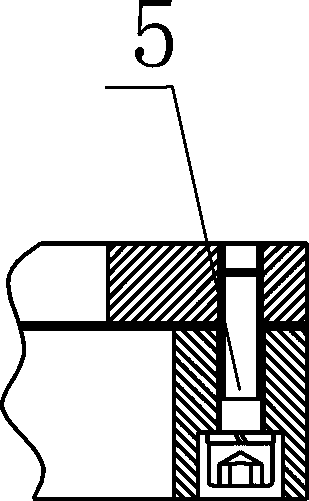

[0018] The upper half seat 6 and the lower half seat 4 are fixedly connected by hexagon socket head cap screws 5 .

[0019] The upper half seat 6 is connected to the lower half seat 4 through a square connection flange. Oil-impregnated asbestos 7 is provided at the positions where the upper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com