Methods of Improving Recovery of Strongly Sensitive Heavy Oil Reservoirs

A heavy oil reservoir, sensitive technology, applied in the direction of chemical instruments and methods, production fluid, earthwork drilling and production, etc., can solve the problems of short thermal recovery production cycle, increased heat loss of oil layer, lack of energy in the oil reservoir, etc., to achieve Improve steam sweep efficiency, reduce oil-water interfacial tension, and effectively control and protect the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

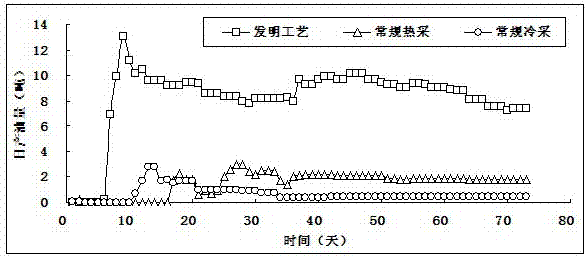

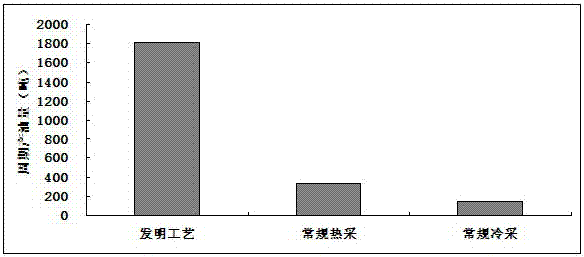

Image

Examples

Embodiment 1

[0037] The method proceeds as follows:

[0038] a. Reservoir condition selection:

[0039] The clay content of the reservoir is 5%, the water sensitivity index is 90%, the thickness of the oil layer is 4m, the buried depth of the oil reservoir is 740m, and the viscosity of degassed crude oil at the oil reservoir temperature is 50000mPa·s;

[0040] b. With 4 parts by weight of hydrochloric acid, 6 parts by weight of hydrofluoric acid, 0.5 parts by weight of polyvinylpyrrolidone slow-release agent, 0.5 parts by weight of ferric citrate ion stabilizer, add water to 100 parts by weight of temperature-sensitive slow-release Acid liquid system, the injection rate is based on the perforation length of the vertical well 6m 3 / m, horizontal well perforation length 0.4m 3 / m, the injection speed is 12m 3 / h to acidify and dissolve the pollution near the wellbore, remove the damage in the formation, and use 6m after treatment 3 The oilfield hot sewage in this area is used as the repla...

Embodiment 2

[0048] The method proceeds as follows:

[0049] a. Reservoir condition selection:

[0050] The clay content of the reservoir is 20%, the water sensitivity index is 70%, the thickness of the oil layer is 10m, the reservoir is buried at 1500m, and the viscosity of degassed crude oil at the reservoir temperature is 1000mPa·s;

[0051] b. With 3 parts by weight of hydrochloric acid, 8 parts by weight of hydrofluoric acid, 0.1 parts by weight of polyvinylpyrrolidone slow-release agent, 1 part by weight of ferric citrate ion stabilizer, add water to 100 parts by weight of temperature-sensitive slow-release Acid liquid system, the injection rate is based on the perforation length of the vertical well 4m 3 / m, horizontal well perforation length 0.6m 3 / m, the injection speed is 8m 3 / h to acidify and dissolve the pollution near the wellbore, remove the damage in the formation, and use 12m after treatment 3 The oilfield hot sewage in this area is used as the replacement fluid for d...

Embodiment 3

[0059] The method proceeds as follows:

[0060] a. Reservoir condition selection:

[0061] The clay content of the reservoir is 5%, the water sensitivity index is 90%, the thickness of the oil layer is 4m, the buried depth of the oil reservoir is 740m, and the viscosity of degassed crude oil at the oil reservoir temperature is 50000mPa·s;

[0062] b. With 4 parts by weight of hydrochloric acid, 6 parts by weight of hydrofluoric acid, 0.5 parts by weight of polyvinylpyrrolidone slow-release agent, 0.5 parts by weight of ferric citrate ion stabilizer, add water to 100 parts by weight of temperature-sensitive slow-release Acid liquid system, the injection rate is based on the perforation length of the vertical well 6m 3 / m, horizontal well perforation length 0.4m 3 / m, the injection speed is 12m 3 / h to acidify and dissolve the pollution near the wellbore, remove the damage in the formation, and use 6m after treatment 3 The oilfield hot sewage in this area is used as the repl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com