Spun polyester pre-oriented yarn production method using recycled polyester bottle chips

A production method and technology for pre-oriented filaments, which are applied in the directions of melt spinning, melting of filament raw materials, and bundling of newly ejected filaments, to achieve the effects of small investment, reasonable and practical technology, and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

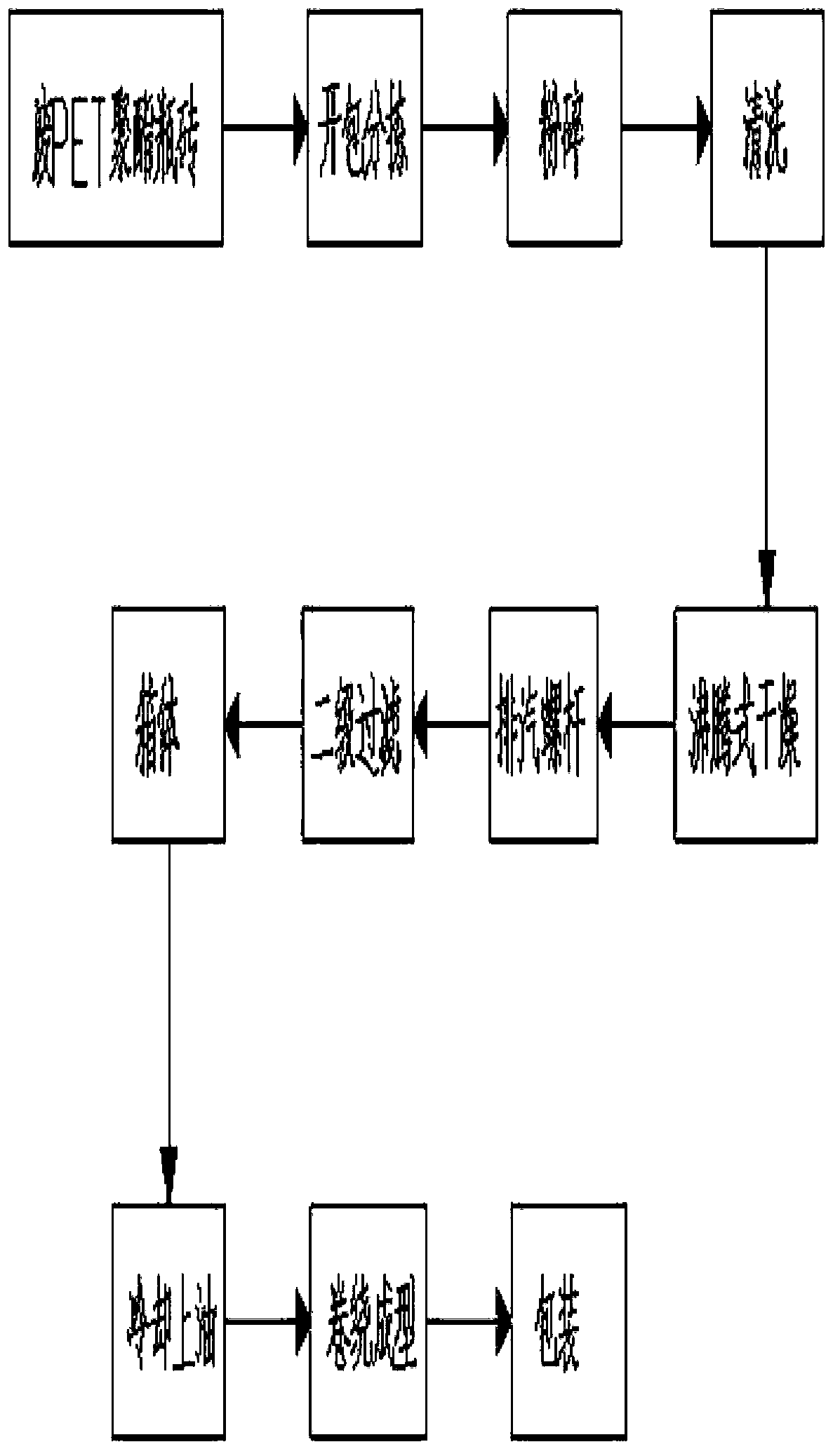

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Implementation example 1

[0026] A kind of production method of recycled polyester bottle flake spinning polyester pre-oriented yarn, its steps are as follows:

[0027] 1. The bottle is broken

[0028] ①. The bottle bricks are unpacked and conveyed by a screw, and impurities (non-PET bottles) are removed on the sorting platform.

[0029] ②. The label paper is removed by the label stripping machine.

[0030] ③, through the screw conveyor to the crusher, crushed into a size suitable for spinning.

[0031] 2. Bottle cleaning

[0032] ①. Pass the broken bottle flakes through a high-speed centrifugal dehydrator to remove the water and part of the mud from the bottle flakes.

[0033] ②. Heat the alkali cleaning pot to about 90°C, add NaOH caustic soda and self-prepared cleaning solution, and clean for about one hour.

[0034] ③. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com