Oligomer mixtures, their production and use as flame retardants and flame-retardant polyurethanes containing them

A technology of mixtures, oligomers, applied in the field of polyurethane foams and polyurethanes, to produce their fields, able to solve problems such as mixtures of oligomers not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

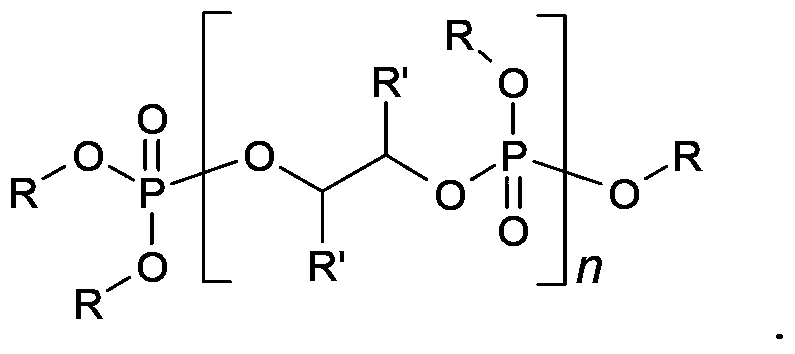

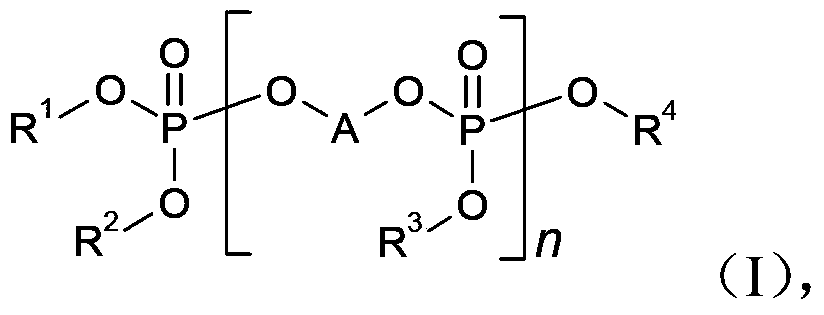

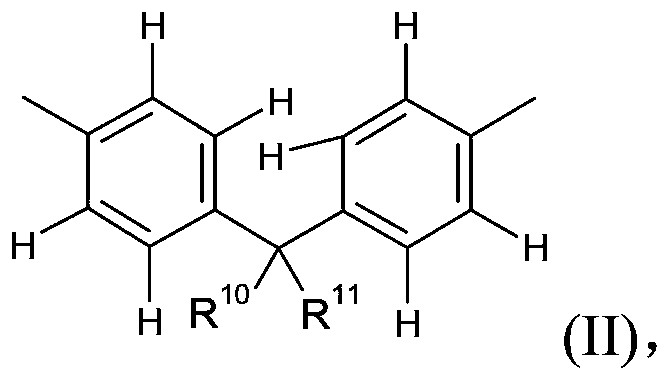

Method used

Image

Examples

Embodiment

[0151] Description of the general synthesis for oligomer mixtures (Synthesis Examples S1 to S5)

[0152] The phosphorus oxychloride in the amount (parts by weight) stated in Table 1 is charged into a reactor equipped with a stirrer, dropping funnel, reflux condenser and vacuum device. The temperature of phosphorus oxychloride is controlled to 10 to 20°C. Under a vacuum of 500 to 700 mbar, the amount of diethylene glycol indicated in Table 1 was added dropwise. Once the dropwise addition has ended, the pressure is further reduced to a final value of 5 to 15 mbar and the temperature is raised to 20 to 30°C. This gave an almost colorless liquid residue.

[0153] In another reactor with stirrer, dropping funnel and reflux condenser at 20 to 30° C., the amount of ethanol indicated in Table 1 was initially charged and mixed with the residue obtained above. Stirring of the mixture was continued at 20 to 30°C until the reaction was complete, then the mixture was neutralized by addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com