A solid-liquid separation system and separation method for coal washing wastewater

A technology for coal washing wastewater, solid-liquid separation, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low separation efficiency, secondary pollution, and high energy consumption, To achieve the effect of simplifying the process flow, saving water and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

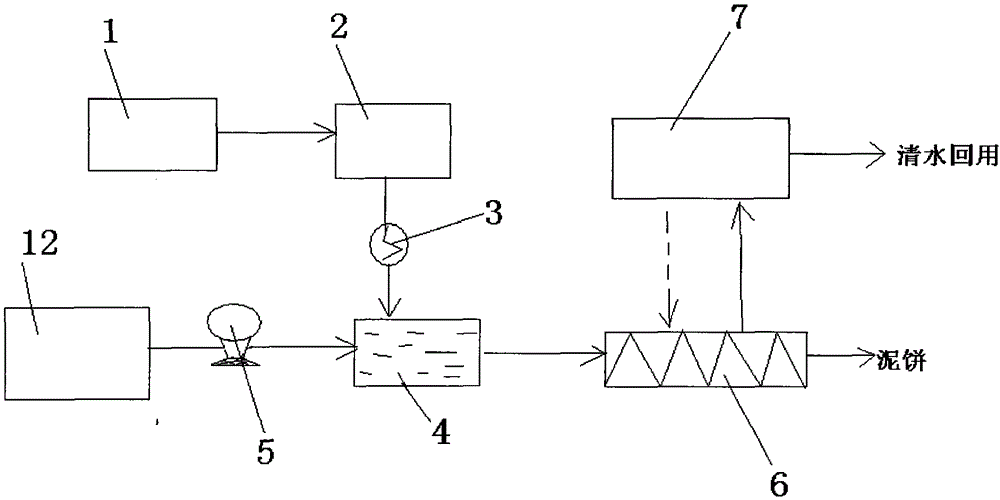

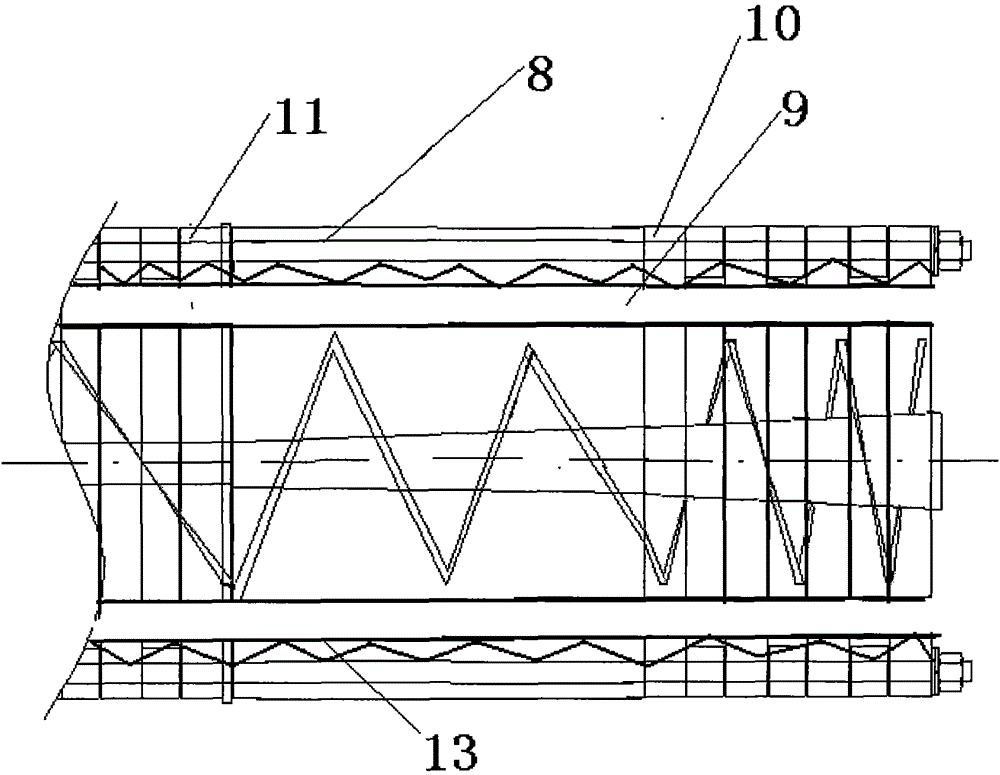

[0020] A solid-liquid separation system for coal washing wastewater, such as Figure 1-2 As shown, the dissolving medicine box 1 is connected to the medicine box 2, the medicine box 2 is connected to the flocculation mixing box 4 through the metering pump 3, the waste water tank 12 is connected to the flocculation mixing box 4 through the water pump 5, and the flocculation mixing box 4 is connected to the coal washing solid-liquid separator 6 are connected, and the coal washing solid-liquid separator 6 is connected with the filtrate clarification tank 7. The coal washing solid-liquid separator 6 is a stacked screw sludge dewatering machine. The screw stack main body 8 of the screw stack type sludge dewatering machine is provided with a filter tube 9, and the filter tube 9 is arranged between the moving ring filter 10 and the fixed ring filter 11 of the screw stack body 8. The screw-stacked sludge dewatering machine is equipped with an automatic spraying device 13 .

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com