High-energy pulse ozone generator

An ozone generator and high-energy pulse technology, which is applied in ozone preparation, transformers, inductors, etc., can solve the problems of low efficiency, large volume, and high cost of ozone generators, and achieve the effects of simple structure, high efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

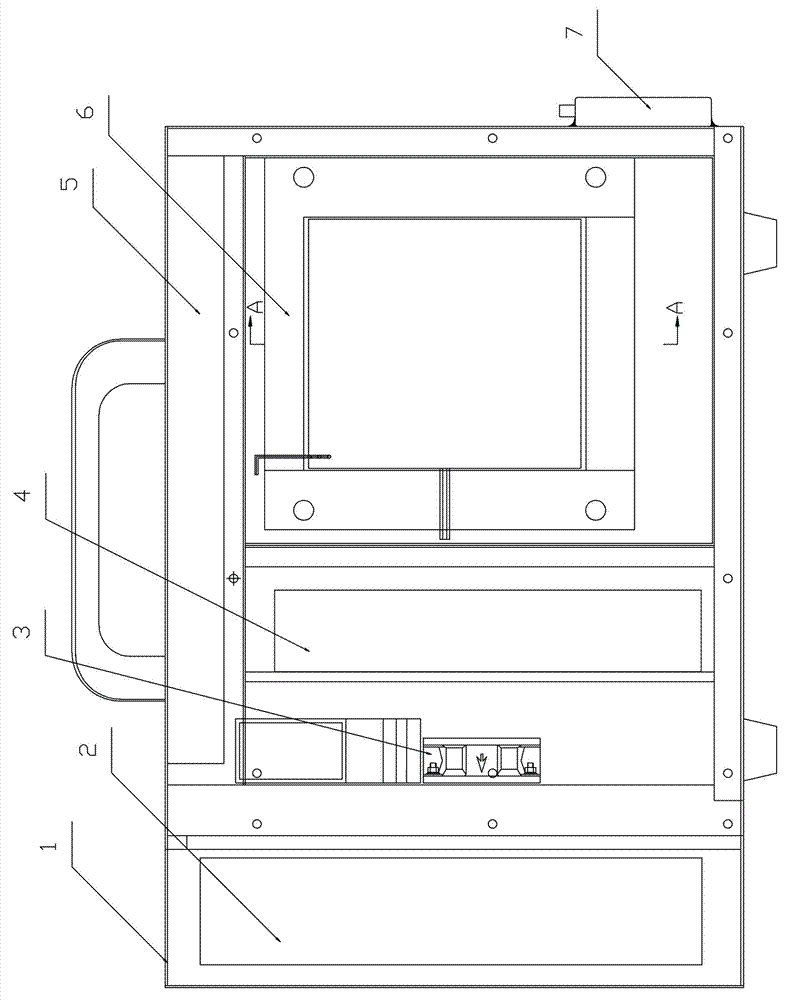

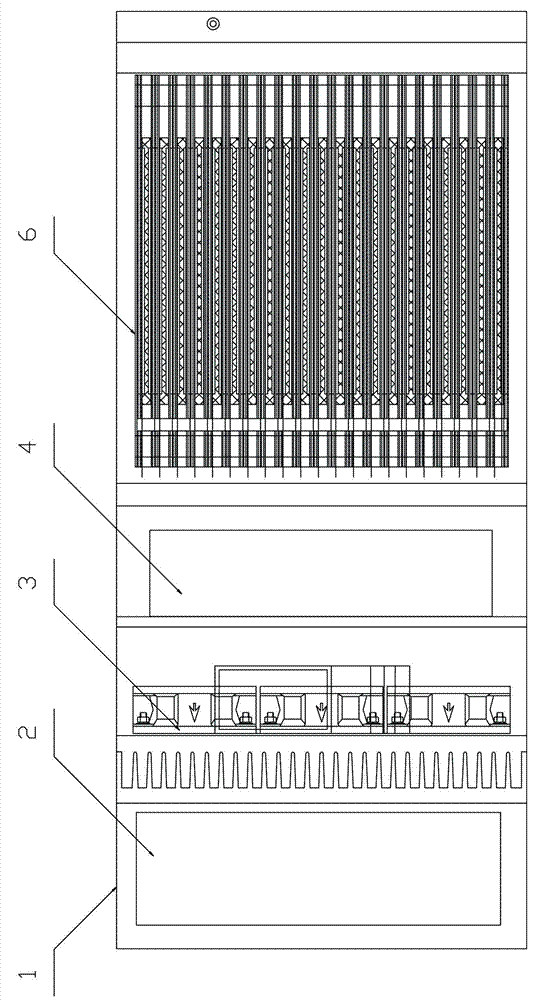

[0034] see figure 1 —9, the present invention has housing 1, and pulse transformer 4 and ozone generation unit 6 and pulse generation controller 2 are installed in housing 1, and pulse generation controller 2 is connected pulse transformer 4 and ozone generation unit 6 respectively, and housing 1 There is also an ozone discharge port 7 on the top, especially: the ozone generating unit 6 includes several groups of stacked main plate assemblies, and the auxiliary plate 12 is sandwiched between the two main plate assemblies (see Figure 5 , the four corners of the main plate assembly are provided with bolt holes 16 through which the bolts are installed as a whole), each set of main plate assembly includes two front and rear mica separators 8 and 11, and two left and right mica separators between the front and rear mica separators 8 and 11 An insulating spacer 14 is arranged on the side, and a cavity is formed in the middle, and a mica substrate 10 is housed in the cavity. Several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com