Meridianal bias tire with low flatness ratio

A bias-ply tire and flat rate technology, which is applied to tire parts, reinforcement layers of pneumatic tires, vehicle components, etc., can solve the problems of driving speed and continuous driving mileage that cannot be broken through, and achieve a more rational and enhanced shape of the ground contact mark. Rigidity, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

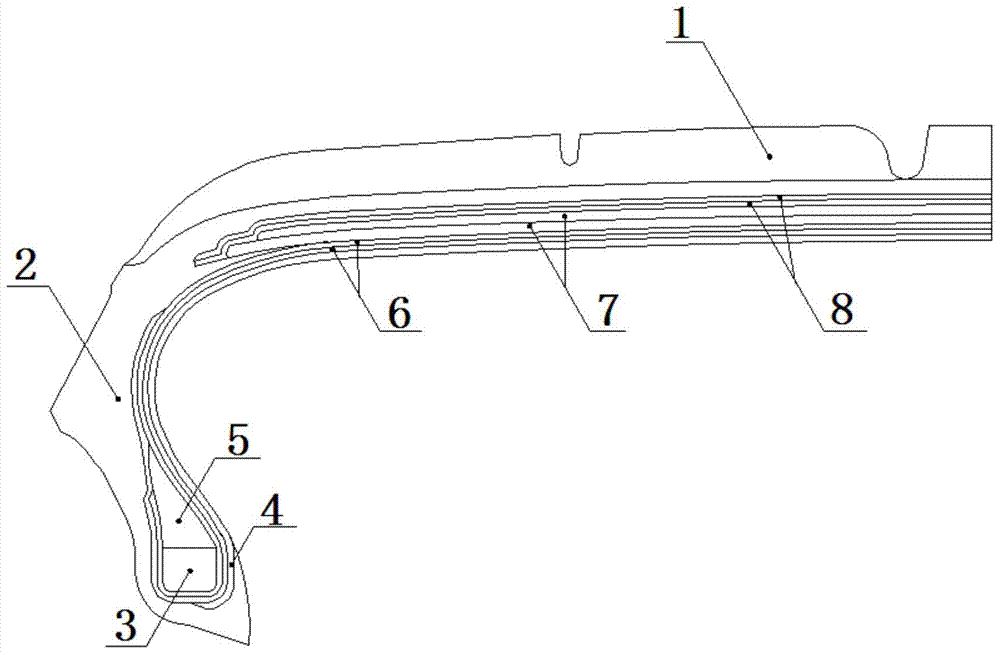

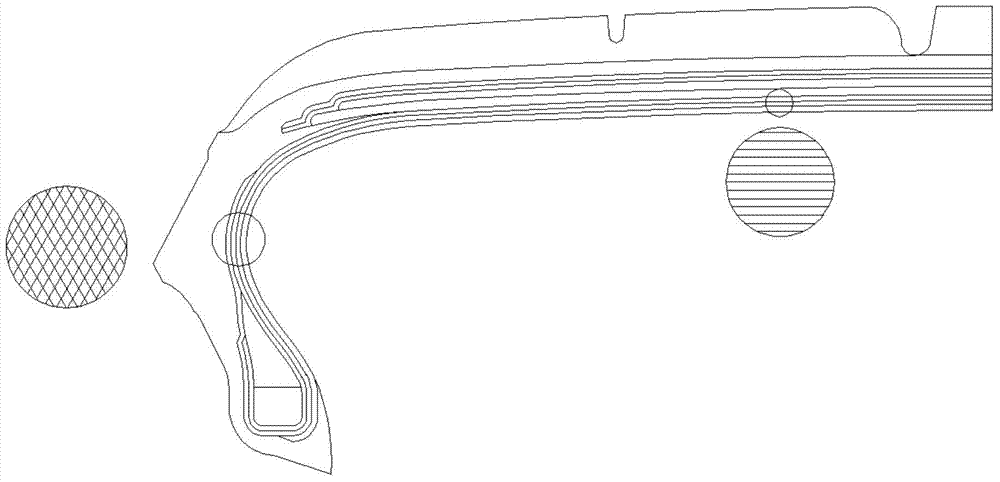

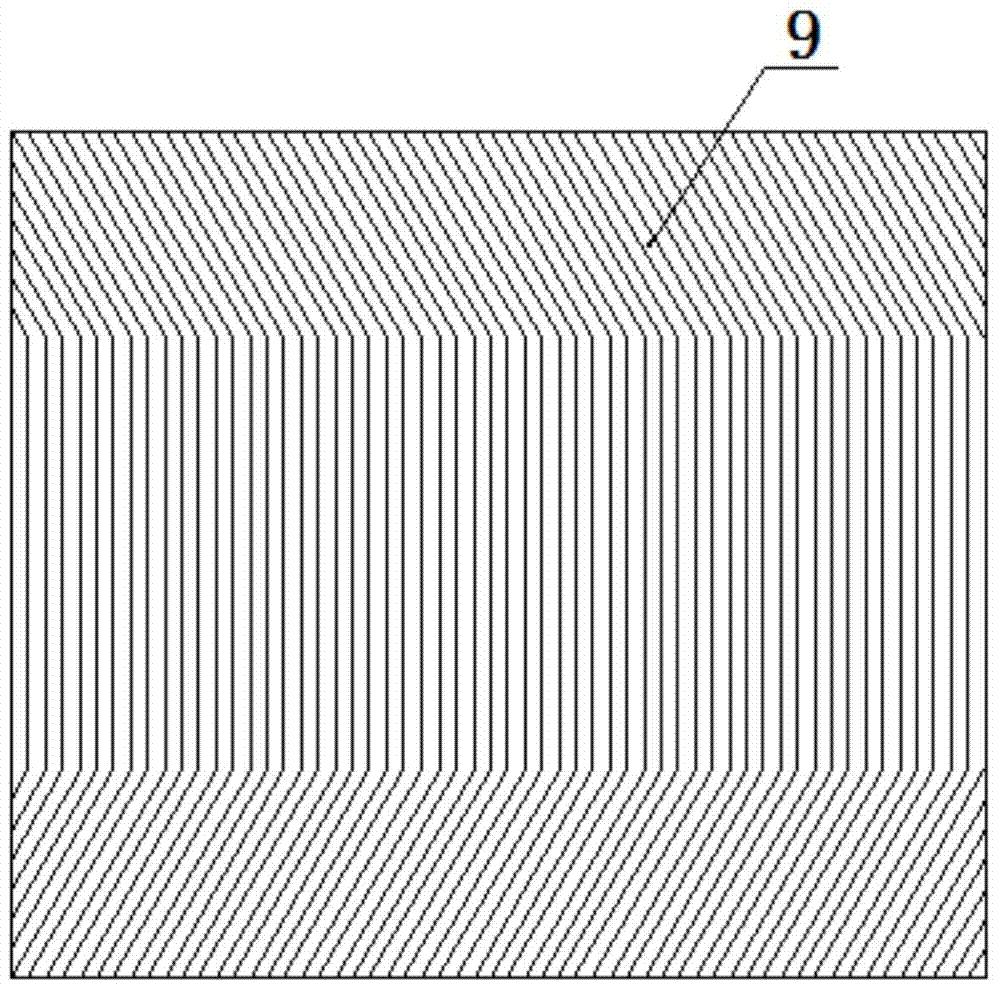

[0019] The present invention proposes a radial bias tire suitable for low profile, such as figure 1 , figure 2 As shown, the tire structure mainly includes tread rubber 1, sidewall rubber 2, bead 3, inner liner 4, apex 5, carcass layer 6, belt layer 7, cap layer 8, and tread rubber 1 is located at On the radially outermost layer of the tire, the sidewall rubber 2 is located below the two sides of the tread rubber 1 and is closely connected with both ends of the tread rubber 1. Small, the bead 3 is located under the sidewall rubber 2, the airtight layer 4 is located at the innermost layer of the inner contour of the tire, the apex rubber 5 is located inside the bead 3, the carcass layer 6 is located outside the airtight layer 4, and the carcass layer 6 The material is polyester material, and the carcass layer 6 includes rubber 11 and carcass cords 12. In order to have the better high-speed performance of radial tires and the better high load-bearing performance of bias tires,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com