Automatic welding control method and system based on dual-mode real-time welding seam tracking

An automatic control and real-time tracking technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of less research on automatic tracking, achieve important practical application value, strong flexibility, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

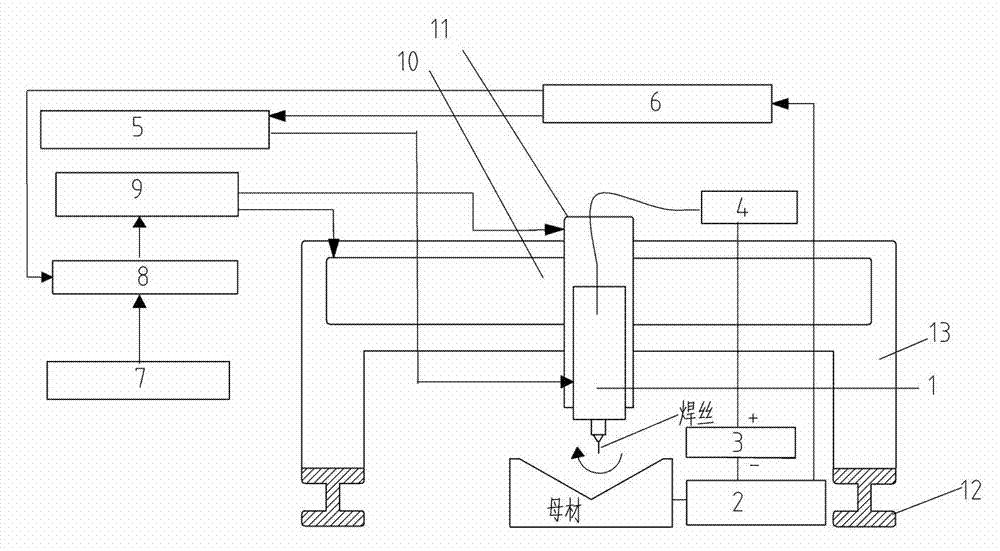

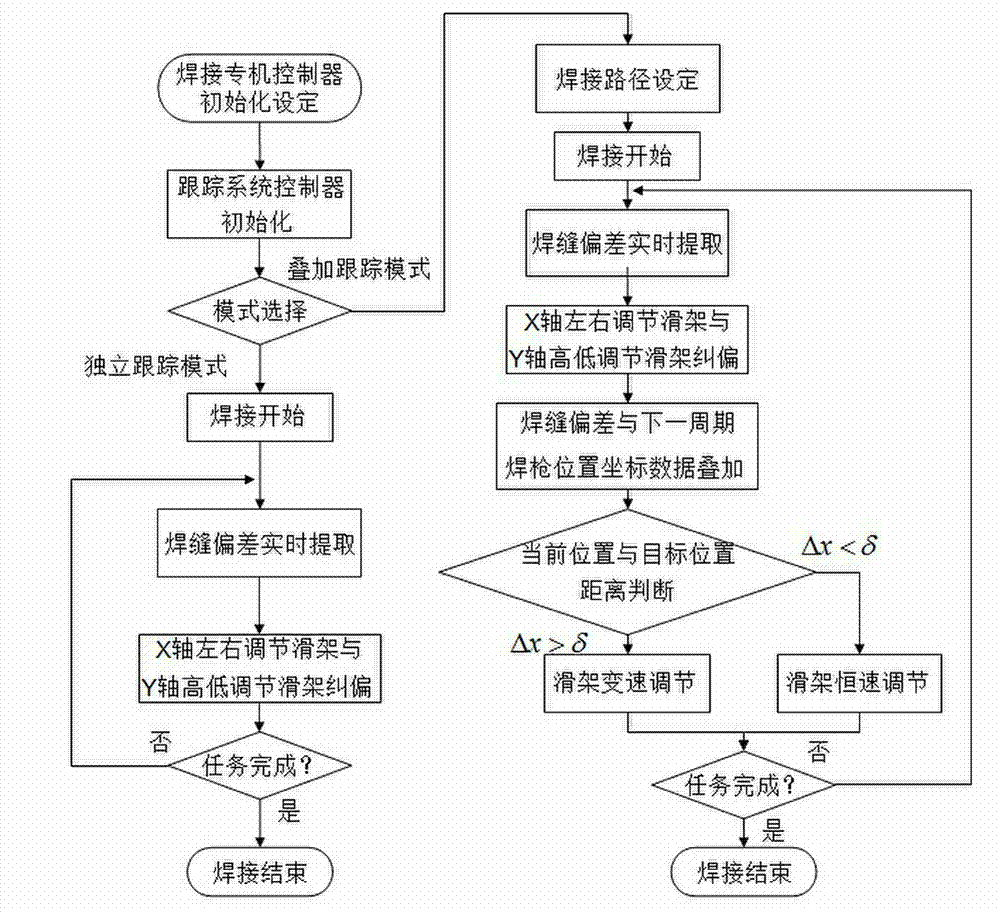

[0019] Embodiment 1, the present invention adopts a welding automation control method based on dual-mode real-time weld seam tracking. The automatic welding control method of mode real-time seam tracking realizes automatic welding. The specific control method includes: before welding starts, first perform welding initialization setting work on the welding special machine controller 8, including setting the welding initial position, process parameters, etc.; and initializing the rotary arc tracking system controller 6, including The arc rotation frequency of the rotating arc sensor head 1, the arc scanning radius, system initialization, etc.; secondly, the automatic welding mode is selected according to the production task, and two automatic welding control modes are provided: Mode 1 is superimposed tracking mode, that is, the preset welding mode The path is the main path, which is equivalent to the rough adjustment of the welding special machine system during weld seam trackin...

Embodiment 2

[0020] Embodiment 2, the weld deviation identification method based on rotating arc sensing includes interval integration method, or left and right extremum method, or characteristic harmonic method, or neural network method, or support vector machine method, the present invention adopts the method developed by Tsinghua University The interval integration method proposed by Pan Jiluan, Wu Shide, etc. refer to Figure 1 to Figure 2 , all the other are with embodiment 1.

Embodiment 3, 1 system , system and system , system system , system and system 。 Embodiment 4

[0021] Embodiment 3, the present invention also provides a welding automation control system based on dual-mode real-time seam tracking, which includes a real-time seam tracking system and a numerically controlled welding machine system, and the real-time seam tracking system is based on a rotating arc sensor A welding seam real-time tracking system, the welding seam real-time tracking system is connected with the numerical control welding special machine system by using a signal control circuit. Embodiment 4, the special welding machine system includes a special welding machine power supply 7, a special welding machine controller 8, a special welding machine driver 9, an X-axis left and right adjustment carriage 10, a Y-axis height adjustment carriage 11, a welding special machine guide rail 12, and a welding special machine The motors on the frame 13 and the welding plane, the welding plane controller 8 is connected to the welding plane power supply 7, and is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com