The production method of molybdenum target

A production method and technology of molybdenum target, applied in the field of semiconductor manufacturing, can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

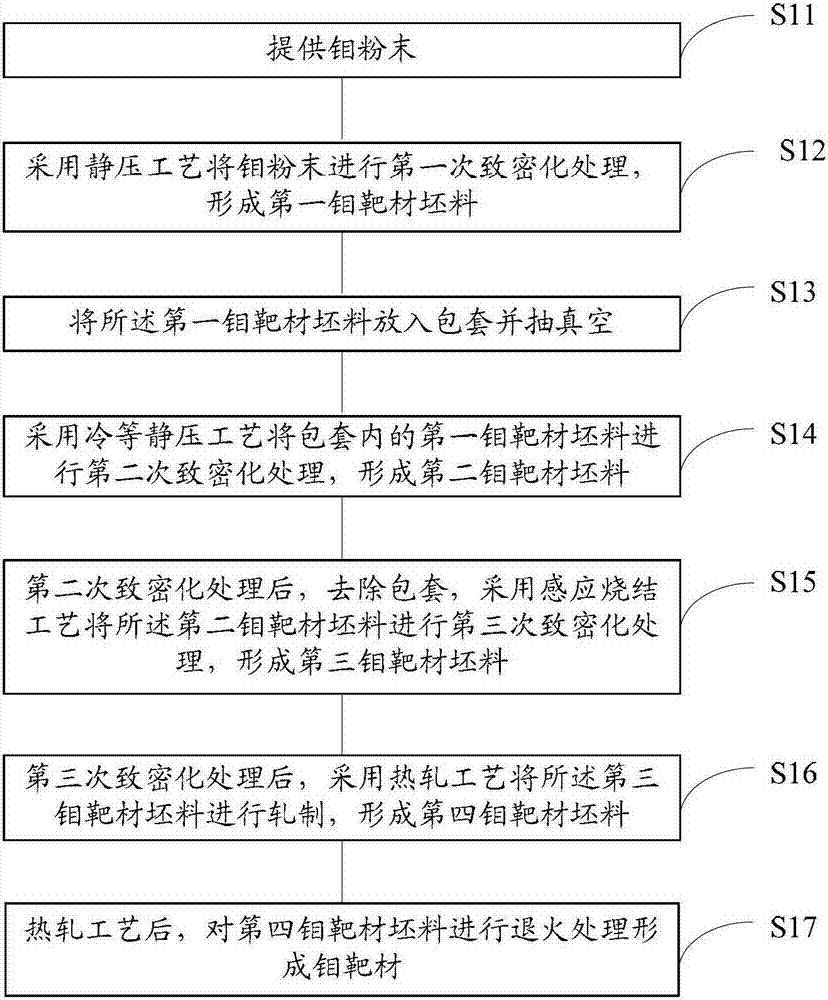

Method used

Image

Examples

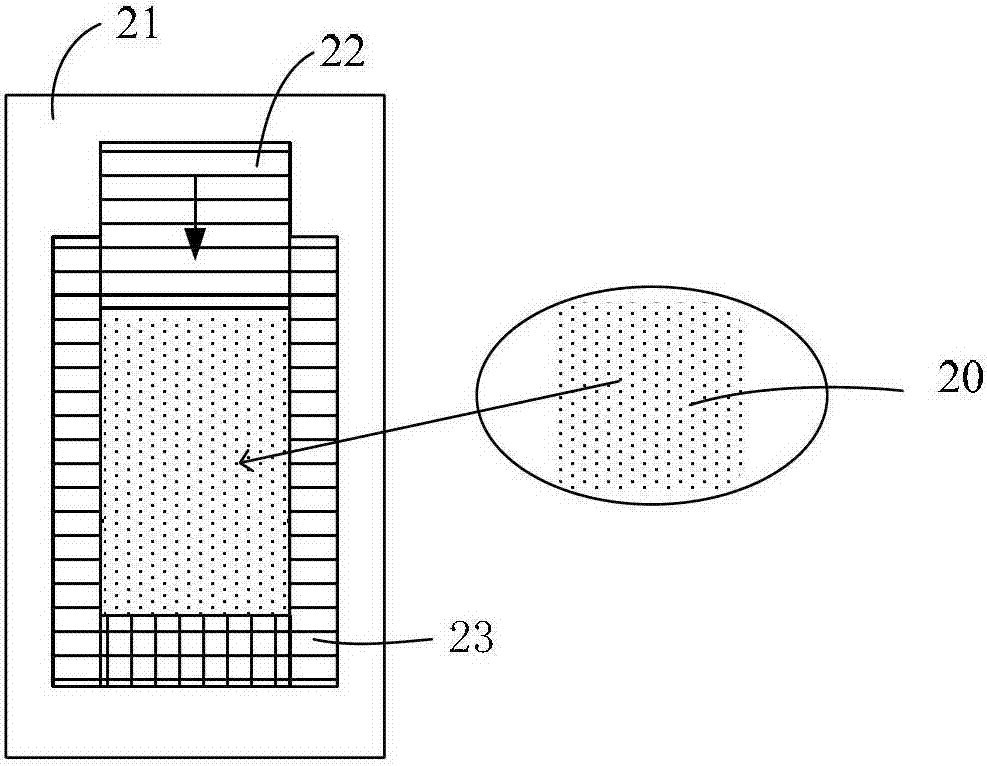

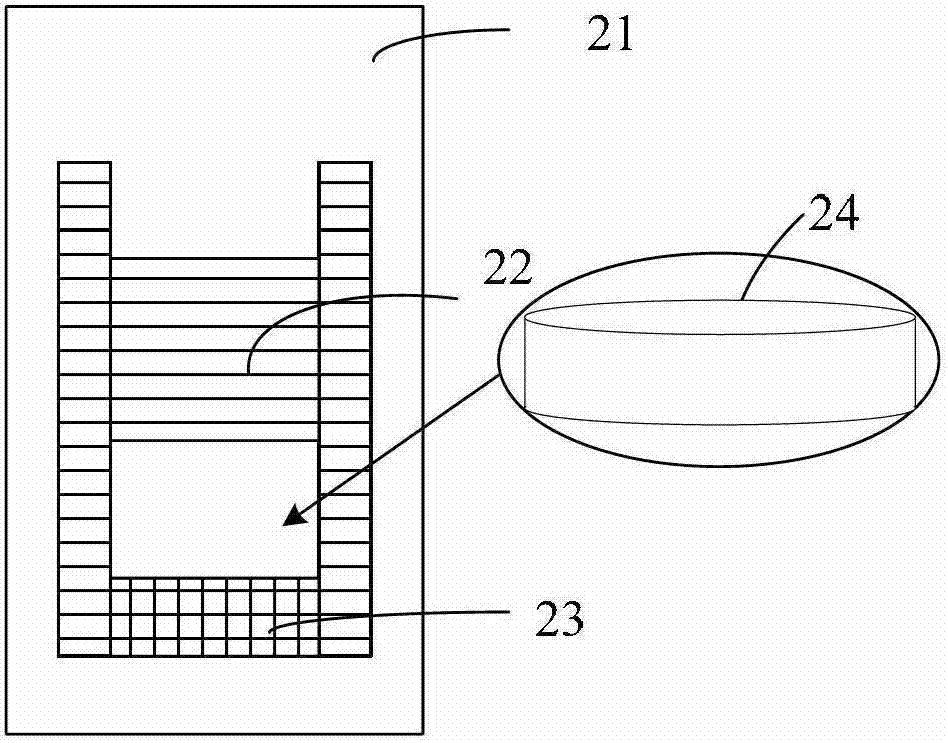

Embodiment Construction

[0057] The inventors have found and analyzed that the existing powder metallurgy process commonly used hot pressing process (HotPressing, HP). In the vacuum hot-press furnace, the powder is compacted first, then vacuumed to the set value, followed by increasing the temperature and pressurizing until both the pressure and temperature reach the set value, heat preservation and pressure for a period of time, then cool with the furnace and come out of the furnace.

[0058] Molybdenum has a high melting point of 2600°C. The hot pressing process is used to sinter the molybdenum powder to form a fully dense (more than 99% dense) molybdenum target. The required pressure is greater than or equal to 100MPa. The hot pressing process is one-way pressure. On the one hand, it will exceed the pressure limit of the graphite mold, on the other hand, the grains of the molybdenum powder will be unevenly stressed in all directions, and the internal structure of the molybdenum target formed is not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com