Crushing pair with superfine crushing function and implementation method of superfine crushing function thereof

An ultra-fine crushing and functional technology, applied in the field of crushing, can solve the problem of low crushing efficiency in the crushing cavity, and achieve the effect of increasing jaw crushing capacity, reducing wear and improving crushing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

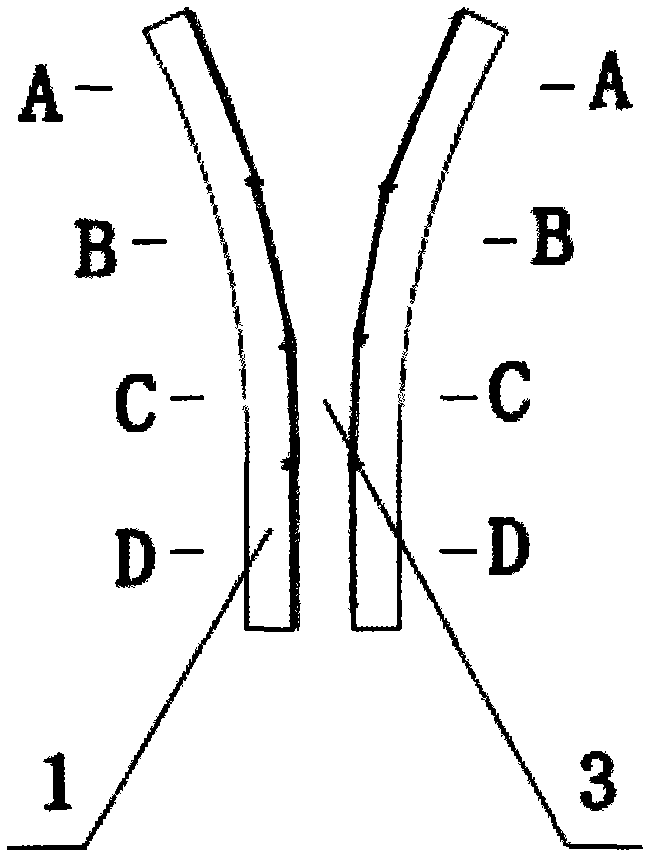

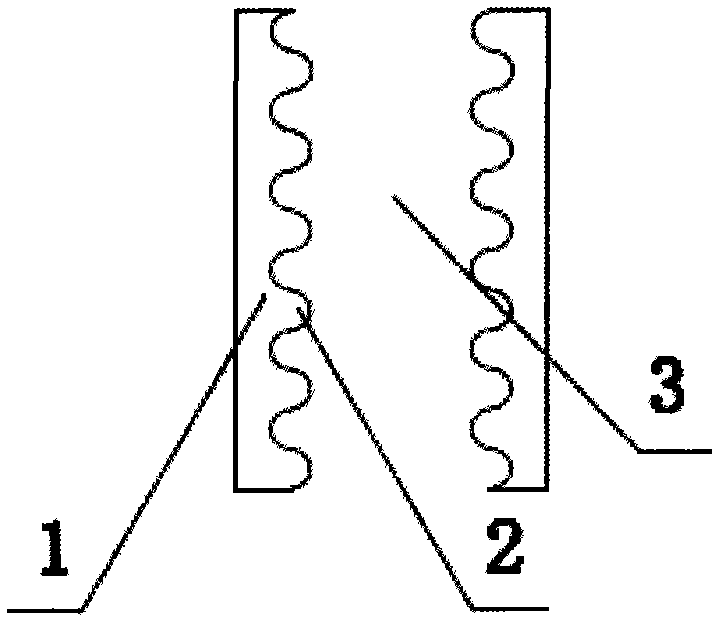

[0119] Embodiment 1: as figure 1 , image 3 , Figure 4 , Figure 5 with Image 6 As shown in the figure, a jaw plate with ultra-fine crushing function of the jaw crushing chamber includes two jaw plates 1 facing each other to form at least two stepped structure crushing chambers, and tooth-shaped structures 2 are arranged on the working surfaces of the two jaw plates; the stepped structure crushing chamber 3 The angle formed by the confrontation between the two jaw plates of the working face gradually decreases from top to bottom, forming an angle ladder structure; the tooth structure 2 on the two jaw plate working faces of the stepped structure crushing chamber 3 also moves from top to bottom according to the The stages gradually become smaller, that is, the tooth height gradually becomes lower, the tooth width gradually narrows, and the tooth spacing gradually becomes smaller, showing a tooth-shaped ladder structure.

[0120] In the stepped crushing chamber 3, the worki...

Embodiment 2

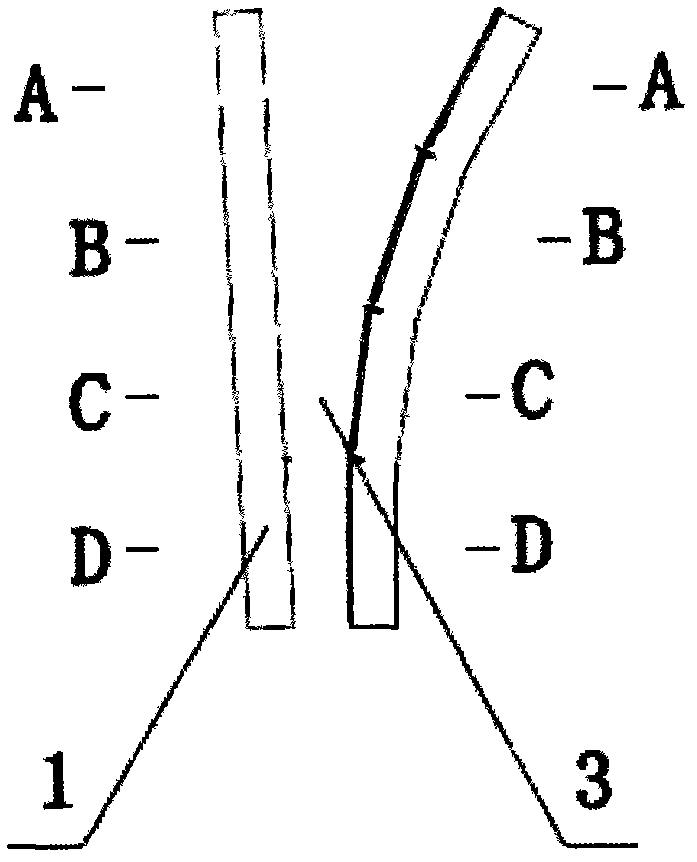

[0123] Embodiment 2: as figure 2 As shown, in the stepped crushing chamber 3, the working faces of the two jaw plates 1 located at the bottom of the final stage of the crushing chamber are narrow and long, and the angle range formed by the confrontation between the two jaw plates 1 working faces is +3 degrees; forming a long and narrow structure The length of the working surfaces of the two jaw plates is 550mm, and one of the working surfaces of the two jaw plates 1 forming a long and narrow structure is a flat light plate structure.

[0124] The stepped crushing chamber 3 has a four-level stepped structure. The two jaws of the stepped crushing chamber 3 are spliced separately.

[0125] In the stepped crushing chamber, the shape of each stage of the crushing chamber is a trapezoidal structure with a left-right asymmetrical top and a bottom.

[0126] All the other are with embodiment 1.

Embodiment 3

[0127] Example 3: In the stepped crushing chamber 3, the working faces of the two jaws 1 located at the bottom and the last stage of the crushing chamber are narrow and long, and the length of the two jaws forming the long and narrow structure is 300mm.

[0128] All the other are with embodiment 1.

[0129] A method for realizing a crushing pair with an ultra-fine crushing function is characterized in that it includes the following content:

[0130] 1. The structural design of the long and narrow crushing cavity (located at the bottom of the crushing cavity of the whole crusher);

[0131] The jaw crusher is characterized by periodic cycle work, that is, it takes each revolution of the eccentric shaft as a cycle. Since the feeding speed of the jaw crusher is the free fall speed, as long as the speed of each crusher is determined, the material drop (that is, the distance the material is pushed) in each cycle of the crusher is a definite value. At this time, the cavity width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com