Tobacco leaf modulating and stalk-removing method and cutter

A technology for tobacco leaves and tobacco stems, which is applied in the field of tobacco leaf modulation and destemming treatment methods and knives, can solve the problems of cumbersome manual destemming operations, time-consuming and labor-intensive, and reduced production efficiency, achieves bright appearance, overcomes technical bottlenecks, and is easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Harvest the flue-cured tobacco leaves suitable for ripening in the field, align the base ends or petiole ends of about 50 tobacco leaves, and use a common guillotine with a length of about 60 cm to cut off the leaf base ends accounting for 1 / 3 of the leaf length to remove the leaf bases; per person per hour It can handle 500-1000kg of tobacco leaves; put the tobacco leaves with the leaf base removed into a professional smoke box or rack, push the smoke box or rack full of leaf base tobacco leaves into the intensive curing room, and complete the process by referring to the intensive baking process of loose leaves In the brewing process, the temperature in the dry gluten stage is lowered by 5-15°C compared with the conventional process, the brewing time in the dry gluten stage is shortened by 12-25 hours, and the overall brewing time is shortened by 20-40 hours; the brewing energy consumption is reduced by about 45%.

Embodiment 2

[0042] Harvest the flue-cured tobacco leaves suitable for ripening in the field, align the base ends of about 10 to 20 tobacco leaves into a handle, and insert the base ends of the tobacco leaves into the feed port of the ordinary rotary cutter-type automatic cutting machine, and cut off the base ends of about The base of the leaf is 1 / 3 of the length of the leaf, and the rotating speed of the cutter head is 500-2000 rpm; each person can process 1000-2000 kg of tobacco leaves per hour; The tobacco boxes or racks of leaf-based tobacco leaves are pushed into the intensive curing room, and the modulation process is completed by referring to the intensive baking process of loose leaves.

Embodiment 3

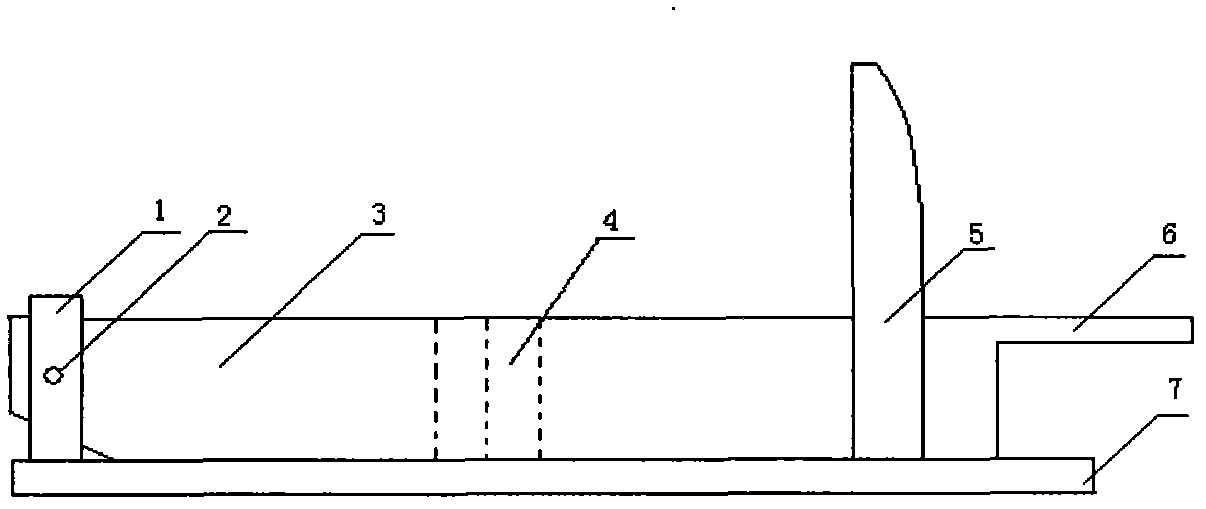

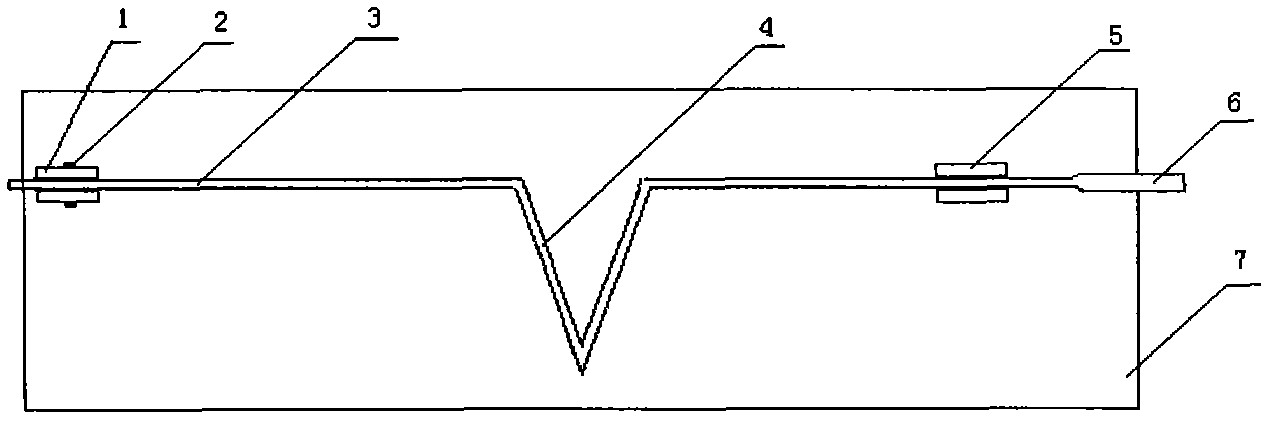

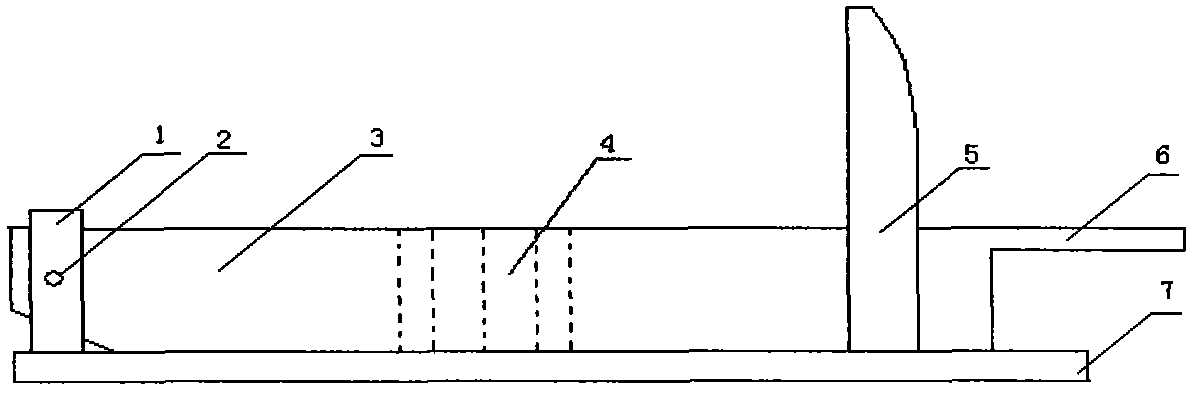

[0044] like figure 1 and figure 2 The shown tobacco leaf destemming guillotine of the present invention is composed of a knife seat 7, a knife body 3, a knife handle 6, a knife head fixing frame 1, a knife shaft 2 and a stabilizing frame 5; the middle section of the knife body 3 has a "V" Glyph bending position 4, and bending position 4 knife surface folding lines are perpendicular to knife holder 7 horizontal planes; Knife body 3 is hingedly installed on the cutter head holder 1 by cutter shaft 2 on the cutter head holder 1; The middle part of the knife body 3 is a "V" shaped knife groove; the angle between the two knife faces of the "V" shaped bending part 4 is 35°; the length of the two knife faces is equal, both are 15cm, and the width of the knife face is 10cm. Knife back thickness 0.3cm; Stabilizer 5 is installed near knife handle 6 ends of cutter body 3, and stabilizer 5 can keep cutter body 3 to freely rotate up and down in the chute of stabilizer 5 around cutter sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com