Microgel and method for preparing same, and water-soluble paint composition

A water-soluble paint and microgel technology, applied in the field of microgel and its preparation, can solve the problems of slow drying time, effect pigment flow, mottling, etc., and achieve the effect of improving interaction, viscosity and pseudoplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

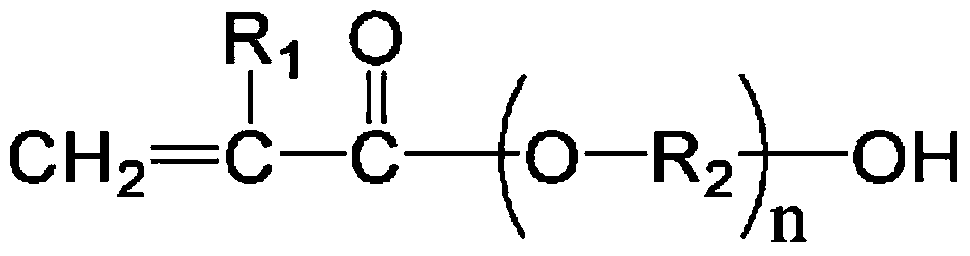

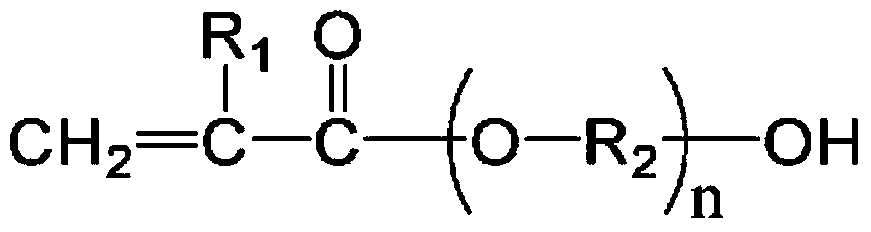

[0022] The preparation method of the microgel in the present invention comprises: the step of preparing a core; the step of forming a first shell on the core; and the step of forming a second shell on the first shell. At this time, the acid-containing unsaturated monomer reacts with the unsaturated monomer having a polyalkylene glycol and containing a hydroxyl group to form a second shell.

[0023] First, according to Example 1 of the present invention, the preparation method of the microgel is described in detail.

[0024] In the step of preparing the core, the acid-free or acid-containing unsaturated monomer, polymerization initiator, emulsifier and ion water are added to the seed crystal to react to form the core. In the step of forming the first shell, an acid-free or acid-containing unsaturated monomer, a hydroxyl-free or hydroxyl-containing unsaturated monomer, a polymerization initiator, an emulsifier and ionized water are added to react to form the first shell. In the...

preparation example 1

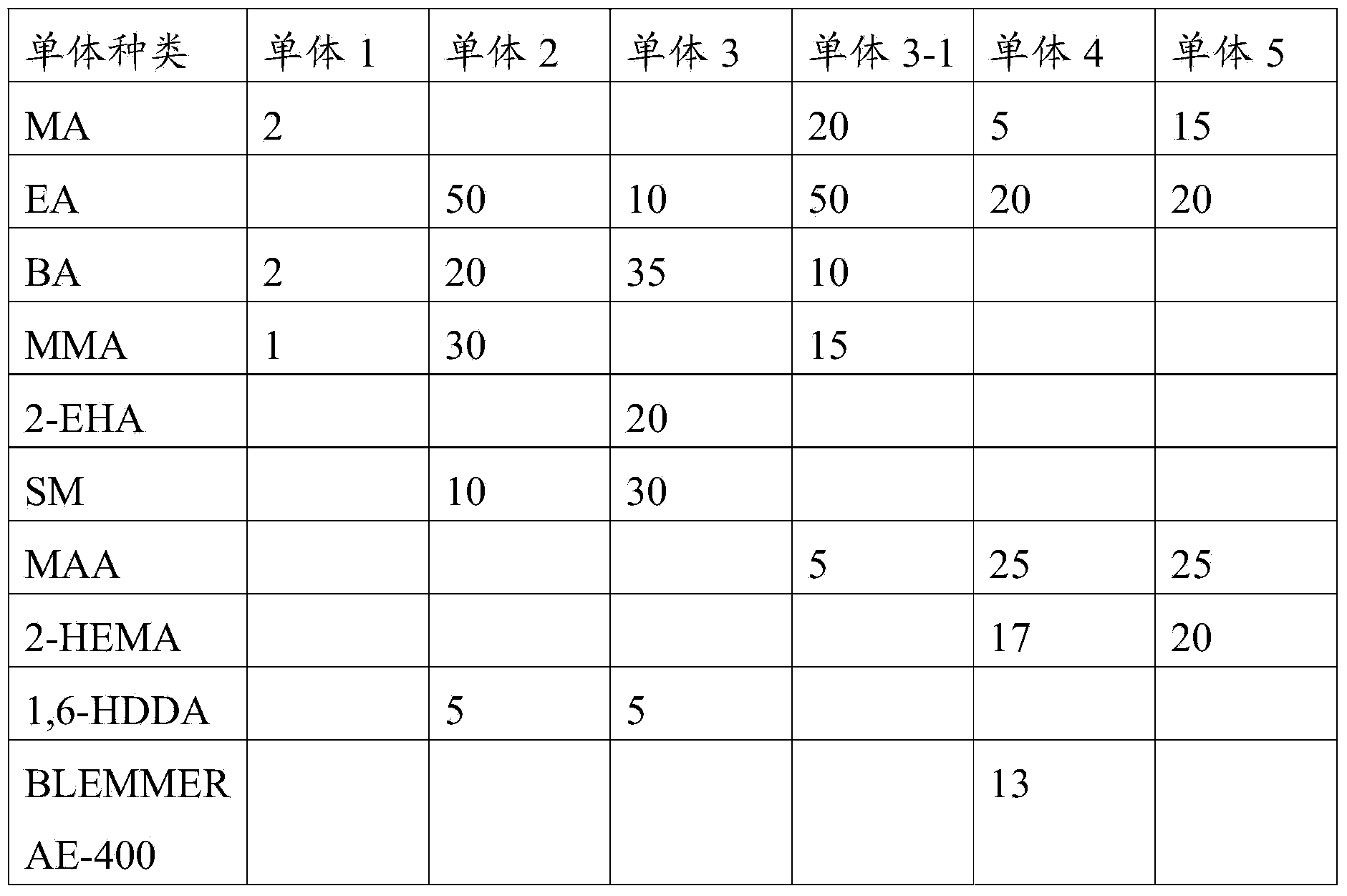

[0090] 140 g of DIW as ionized water, 1 g of CO-436 as an emulsifier, and monomer 1 in Table 1 as a monomer were charged into a 5-liter 4-neck flask equipped with a thermometer, and the temperature was raised to 80°C. Nitrogen was injected for 5 minutes while maintaining the temperature at 80° C., and nitrogen was removed after making the reaction part a nitrogen atmosphere. 3 g of APS as a polymerization initiator was melted in 10 g of DIW, injected into the reactor, and aged for 30 minutes to form seed crystals.

[0091] A preemulsion prepared by mixing monomer 2 of Table 1 and 2.5 g of CO-436 in 100 g of DIW and a polymerization initiator solution obtained by melting 0.5 g of APS in 50 g of DIW were simultaneously dropped for one hour, This was held for one hour to form the core.

[0092] A preemulsion prepared by mixing monomer 3 in Table 1 and 2.5 g of CO-436 in 100 g of DIW and a polymerization initiator solution obtained by melting 0.5 g of APS in 50 g of DIW were simu...

preparation example 2

[0096] 140 g of DIW, 0.5 g of CO-436, and monomer 1 in Table 1 as monomers were charged into a 5-liter four-necked flask equipped with a thermometer, and the temperature was raised to 80°C. Nitrogen was injected for 5 minutes while maintaining the temperature at 80° C., and nitrogen was removed after making the reaction part a nitrogen atmosphere.

[0097] Here, a pre-emulsion with an acid value of 32.6 prepared by mixing monomer 3-1 in Table 1 and 1.25 g of CO-436 in 100 g of DIW was polymerized by melting 0.5 g of APS in 50 g of DIW. The initiator solution was dripped at the same time for one hour, and then maintained for one hour to form the core.

[0098] Here, an aqueous solution obtained by dissolving 20 g of DMEA in 40 g of DIW was added dropwise for neutralization, and after maintaining it for 10 minutes, mixed monomer 2 in Table 1 and 2.5 g of CO-436 in 100 g of DIW. The prepared preemulsion and the polymerization initiator solution obtained by melting 0.5 g of APS i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com