AC permanent magnet gain transformation device and voltage regulating and control method thereof

A transformer device, permanent magnet technology, applied in the direction of transformer, AC power input conversion to AC power output, fixed transformer, etc., can solve the problems of loss, power transfer efficiency reduction, etc. The effect of improving power transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

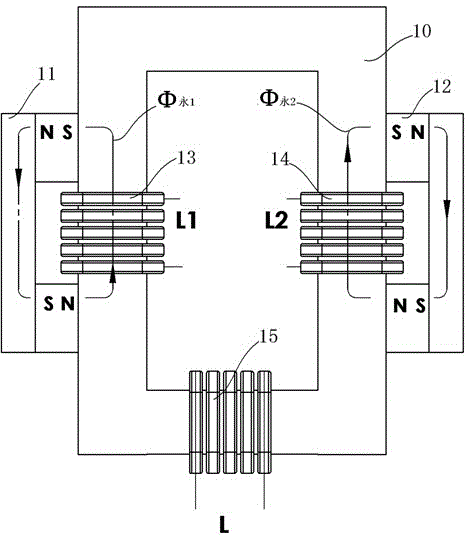

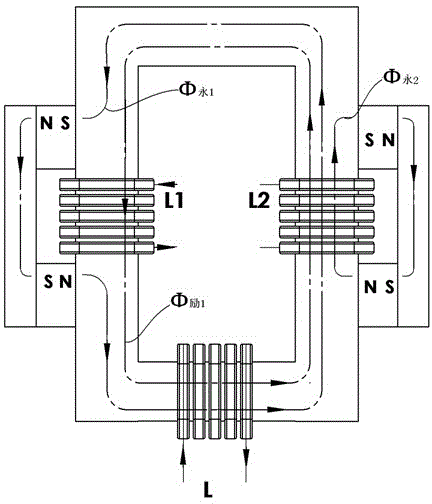

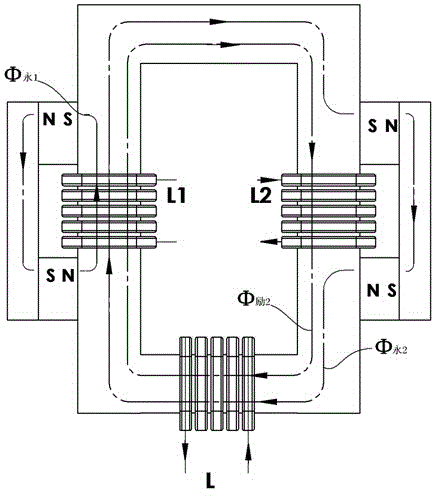

[0033] This embodiment is a transformer with a rectangular closed-loop laminated iron core, and its structure is as follows: figure 1 , 2 , 3 shown.

[0034] The shape of the laminated core 10 in this embodiment is a rectangular closed loop. The primary windings are divided into two groups L1 and L2 and are independent of each other. L1 is wound on the vertical frame on the left side of the rectangular closed loop. The winding method of the primary winding L1 will lead to a unidirectional The direction of the electric excitation magnetic field generated by the pulse current is the same as the direction of the magnetic field generated by the permanent magnet assembly across the primary winding L1, that is, when the current is applied to L1, the laminated iron core above the L1 winding presents S magnetic polarity, and the L1 winding The laminated iron core below presents N magnetic polarity; L2 is wound on the vertical frame on the right side of the rectangular closed loop. Th...

Embodiment 2

[0043] This embodiment is another kind of transformer with a rectangular closed-loop laminated iron core, and its structure is as follows: Figure 4 with 5 shown.

[0044] In this embodiment, the structural forms of the rectangular closed-loop laminated iron core, primary winding, secondary winding, and permanent magnet assembly are the same as in Embodiment 1, the only difference is that the primary windings L1 and L2 are connected in series, and the winding methods of the primary windings L1 and L2 are The following conditions must be met: when the primary windings L1 and L2 input positive pulse currents, the excitation flux Φ generated by L1 and L2 in the overall magnetic circuit of the laminated iron core 励1 and Φ 励2 It is superimposed in the same direction. When the primary winding L1 and L2 input the reverse pulse current, the excitation flux Φ generated by L1 and L2 in the overall magnetic circuit of the superimposed sheet iron core 励1 and Φ 励2 It is also superimpos...

Embodiment 3

[0050] This embodiment is a transformer with a circular closed-loop laminated iron core, and its structure is as follows: Figure 6-12 shown.

[0051] The laminated iron core 21 of this embodiment is made by laminating several layers of iron-based nano-alloy soft magnetic materials with a thickness of 0.003 mm, and the laminated surface of the laminated iron core is perpendicular to the paper surface. as attached Image 6 As shown, two permanent magnets 20, 26 are respectively arranged at the gaps directly above and directly below the laminated iron core. The N magnetic pole of the upper permanent magnet 20 is close to the clockwise laminated iron core. The S magnetic pole is close to the laminated iron core in the counterclockwise direction, and there is an air gap 27 between the inner surface of the upper permanent magnet 20 and the laminated iron core, while the N magnetic pole of the lower permanent magnet 26 is closely connected to the laminated iron core in the counterc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com