Fault Diagnosis System of Rail Grinding Car

A fault diagnosis system and technology for rail grinding cars, which are applied in electrical testing/monitoring and other directions, can solve the problems of inability to remotely monitor the operating status of rail grinding cars in real time and low efficiency, so as to achieve remote monitoring and diagnosis, improve efficiency and ensure accuracy. Effects of Sex and Integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

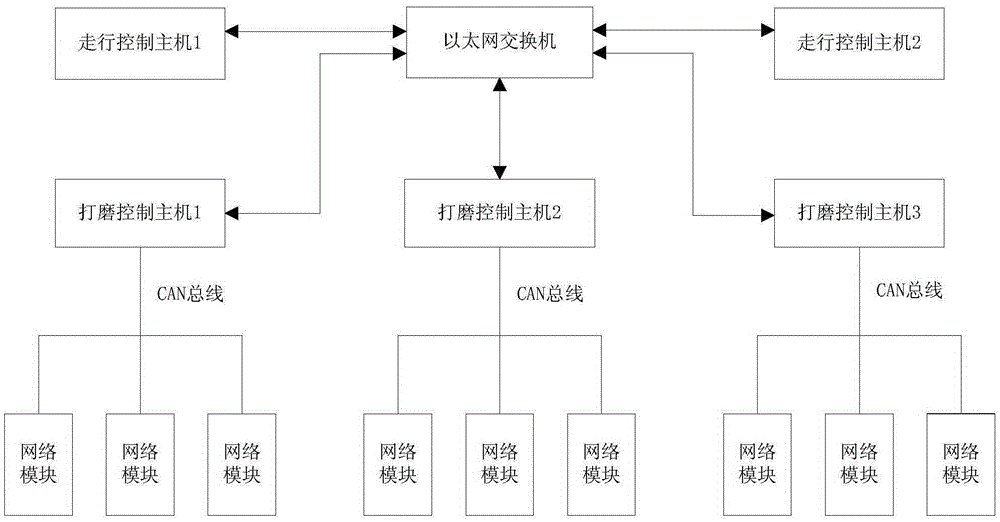

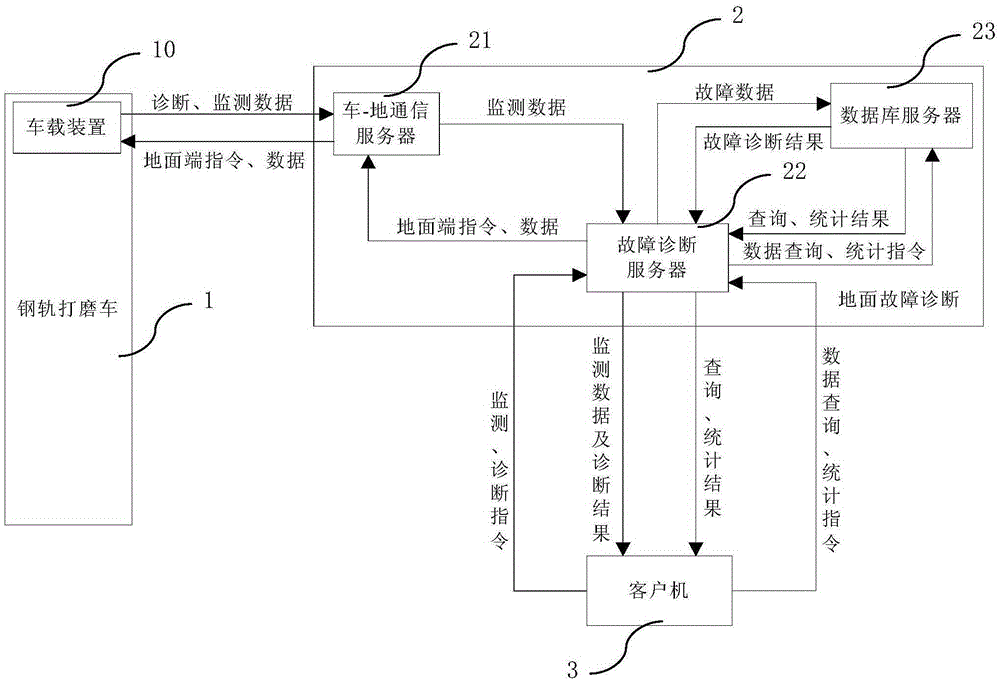

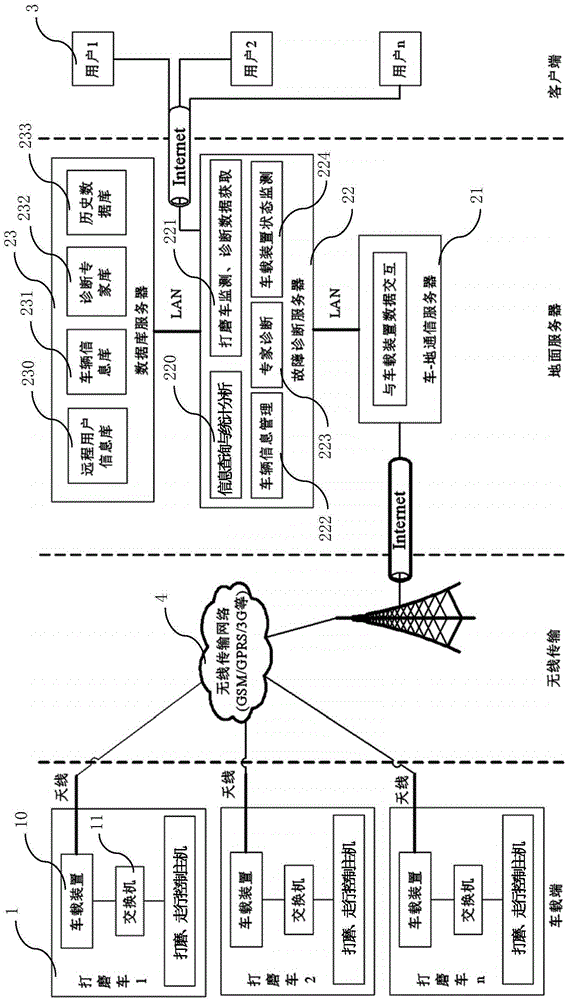

[0059] Embodiment 1: as attached figure 2 And attached image 3 As shown, a specific embodiment of a fault diagnosis system for a rail grinding vehicle includes: a vehicle-mounted device 10 and a ground server 2 , and the vehicle-mounted device 10 is arranged on the rail grinding vehicle 1 . The rail grinding vehicle 1 also includes a switch 11, a network system, a grinding control host 12 and a travel control host 13, and the vehicle-mounted device 10, the switch 11, the grinding control host 12 and the travel control host 13 are connected through a network system, and the ground server 2 includes Vehicle-ground communication server 21, fault diagnosis server 22 and database server 23. The vehicle-mounted device 10 obtains the monitoring and / or diagnosis information of the grinding control host 12 and the running control host 13 through the switch 11, and performs fault analysis to obtain fault phenomenon and fault type information, including fault phenomenon, fault type in...

Embodiment 2

[0063] Embodiment 2: as attached image 3 As shown, on the basis of Embodiment 1, the ground server 2 also includes a database server 23, and the database server 23 adopts the Oracle database system to store various data, and the data is mainly divided into three categories:

[0064] (1) Management data, including vehicle information, user information, unit information, etc.;

[0065] (2) Historical data, including vehicle failure records, vehicle maintenance records, etc. Users can query, analyze and make statistics on fault information through historical data, understand the occurrence rate of various faults, fault distribution and other information, as a reference for vehicle repair and maintenance;

[0066] (3) Diagnosis expert database, including various causes of failures, various failure phenomena, and various failure solutions, etc., is a support library for fault diagnosis.

[0067] The database server 23 further includes a user information database 230 , a vehicle ...

Embodiment 3

[0075] Embodiment 3: If the rail grinding car 1 has multiple different models, then in order to realize the fault diagnosis of the rail grinding car 1, it is first necessary to analyze the Ethernet communication protocols of various types of rail grinding cars 1, and determine the Ethernet communication protocol in the Ethernet data packet. The corresponding relationship between the data and each parameter, so as to extract the required monitoring and diagnosis data. Secondly, analyze the definition of the fault information of the rail grinding car 1, and judge the type and information of the fault occurring at this time according to the extracted diagnostic data. as attached Figure 4 And attached Figure 5 As shown, on the basis of the foregoing embodiments, the vehicle-mounted device 10 is connected to the Ethernet of the rail grinding vehicle 1 through the switch 11, listens to the data sent by the grinding control host 12 and the running control host 13 to the network, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com