Casting piece steel for railway vehicle swing bolster side frame and preparation method thereof

A technology for railway vehicles and castings, which is applied in the field of casting steel for railway vehicle bolster side frames and its preparation, and can solve the problems of long heat treatment time, affecting the grain size of bolster side frames, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

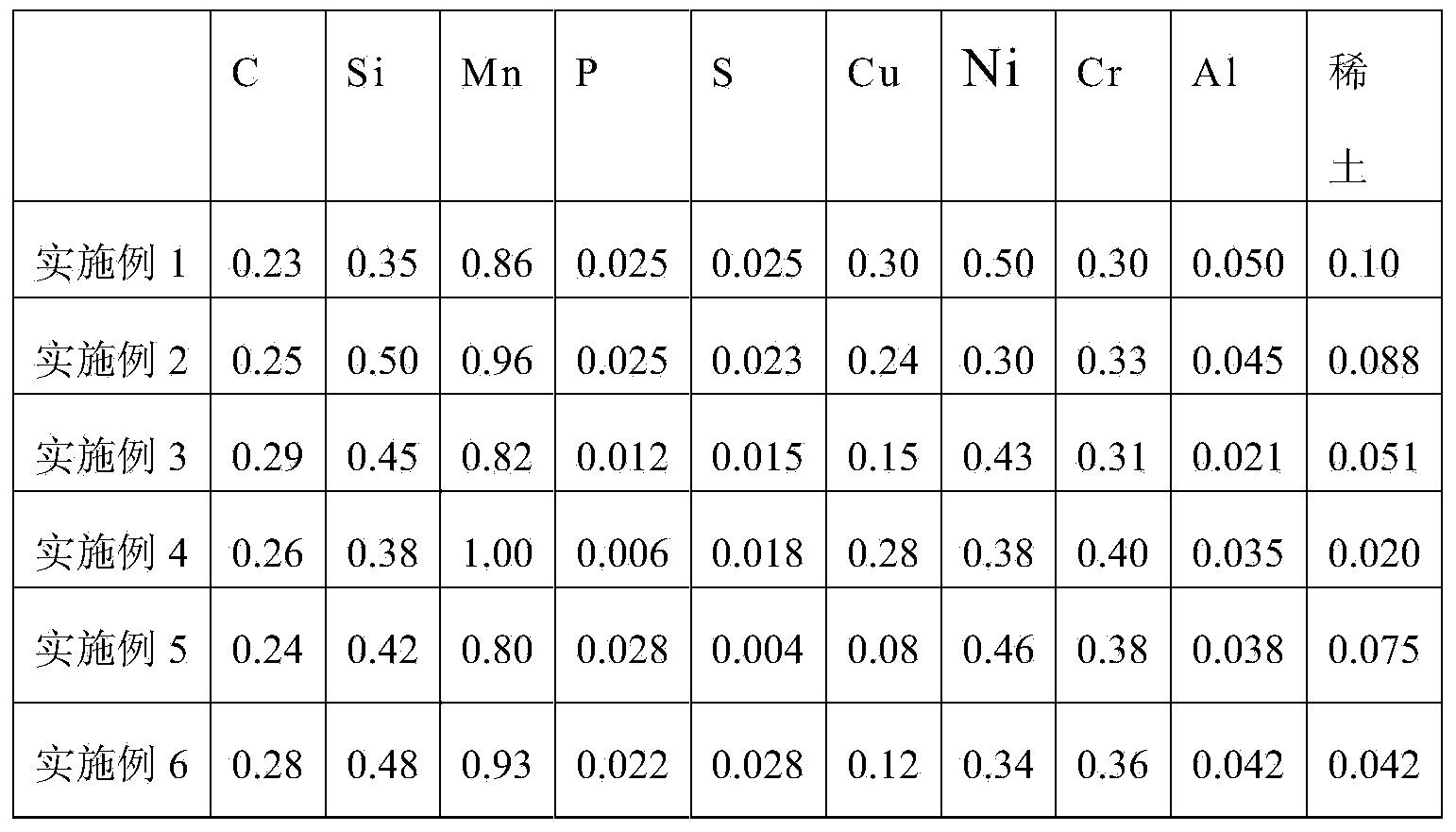

[0025] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

[0026] A casting steel for preparing bolster side frames, the chemical composition of the casting steel is: C: 0.23-0.29%, Si: 0.30-0.50%, Mn: 0.80-1.00%, P≤0.030%, S ≤0.030%, Cu≤0.30%, Ni: 0.20~0.50%, Cr: 0.30~0.40%, Al: 0.020~0.050%, rare earth ≤0.10%, the balance is Fe, wherein, La≤30% in the rare earth , Ce≤70%.

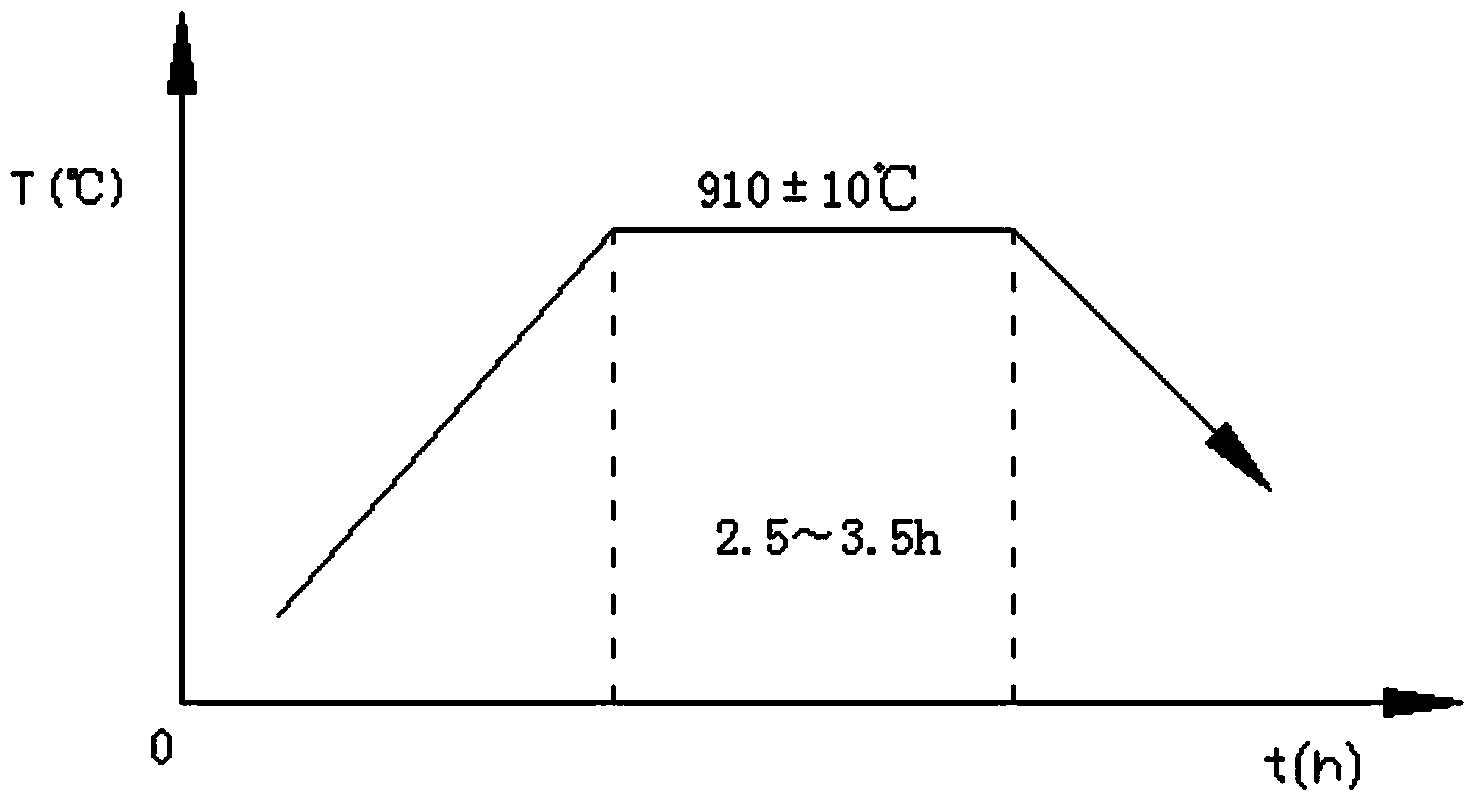

[0027] A method for preparing cast steel, comprising the steps of:

[0028] 1) Weigh according to the above weight percentage: C, Si, Mn, P, S, Cu, Ni, Cr, Al, rare earth corresponding raw materials, set aside;

[0029] 2) Put the raw materials corresponding to C, P, S, Cu and Ni into the eccentric bottom electric arc furnace to melt into molten steel, add 7-9kg of recarburizer per ton of molten steel, and control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com