Process of directly forming and utilizing coal slime of coal cleaning plant

A coal washing plant and coal slime technology, which is applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of increasing the economic benefits of the enterprise and changing the product structure of the enterprise, so as to solve the problem of coal slime stacking, save energy consumption, and avoid coal slime occupation Land and Pollution Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

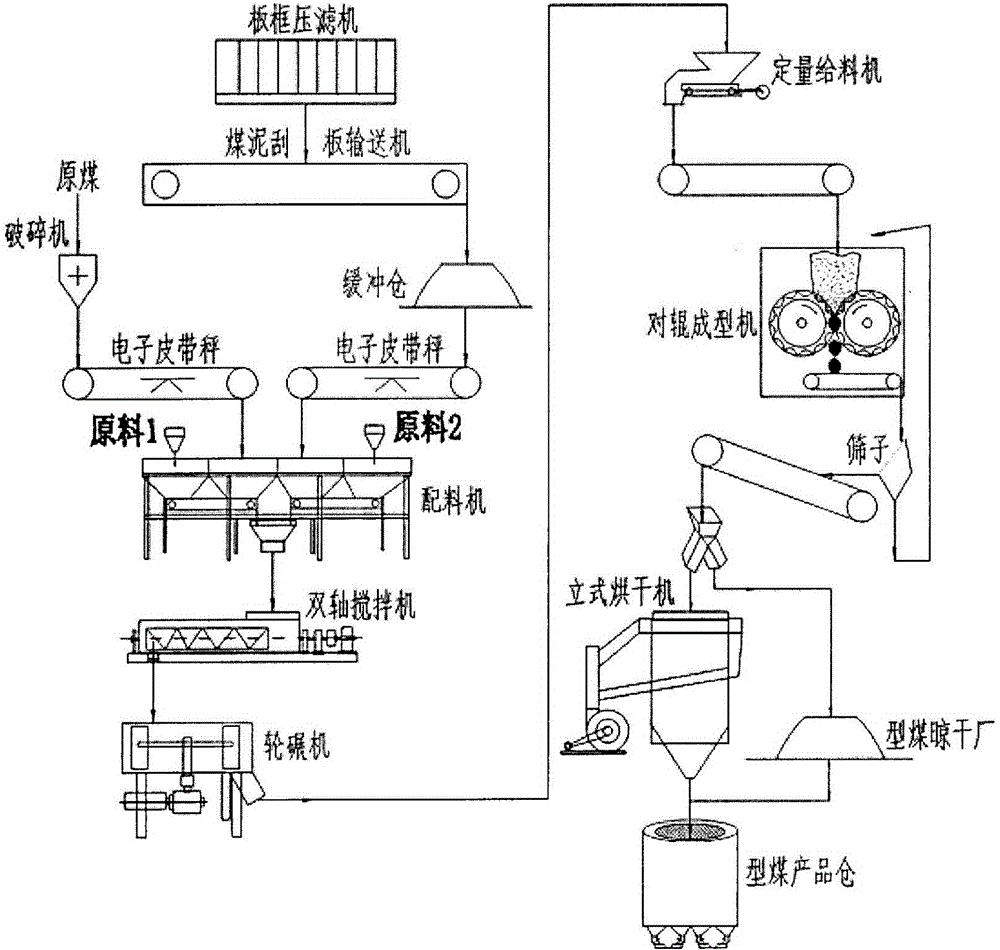

Embodiment 1

[0020] It is measured that the moisture content of the coal slime filter cake coming out of the filter press workshop of the coal washing plant is 28%, the moisture content of the raw coal (broken to below 6mm) is 10.4%, and the moisture content of the feed material of the forming machine is preferably ≤17%. Calculation formula: It can be obtained that the proportion of raw coal needs to be ≥62.5%, the amount of binder mixed is small, and its moisture content can be ignored. The press filter coal slime is directly transported to the batching machine through the scraper conveyor, and is batched with 65% raw coal and 5% Portland cement according to the weight percentage, and the materials are fully stirred and mixed evenly with a mixer and a wheel mill, and then Roll molding or extrusion molding is carried out, and the briquette product is dried naturally. The measured cold compressive strength is 482 N / ball, hot strength is 221 N / ball, drop strength is 93%, and calorific value...

Embodiment 2

[0022] It is measured that the moisture content of the coal slime filter cake coming out of the filter press workshop of the coal washing plant is 28%, the moisture content of the raw coal (broken to below 6mm) is 11.3%, and the feed moisture of the forming machine is preferably ≤17%. Calculation formula: It can be obtained that the proportion of raw coal needs to be ≥66%, the amount of binder mixed is small, and its moisture content can be ignored. The pressure filter coal slime is directly transported to the batching machine through the scraper conveyor, and is mixed with 65% raw coal, 6% sodium humate and bentonite by weight percentage (the mass percentages of sodium humate and bentonite are respectively: 67 %, 33%) for batching, using a mixer and a wheel mill to fully stir and mix the materials evenly, and then carry out roll forming or extrusion molding, and the briquette products are dried. The measured cold compressive strength is 418 N / ball , heat strength 232 N / bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| drop strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com