Desulfurization method for rectified MTBE (methyl tertiary butyl ethers)

A technology of methyl tert-butyl ether and rectification, which is used in ether preparation, ether separation/purification, etc., can solve problems such as high energy consumption and increase production costs, and achieve low energy consumption, complete desulfurization, and less waste discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

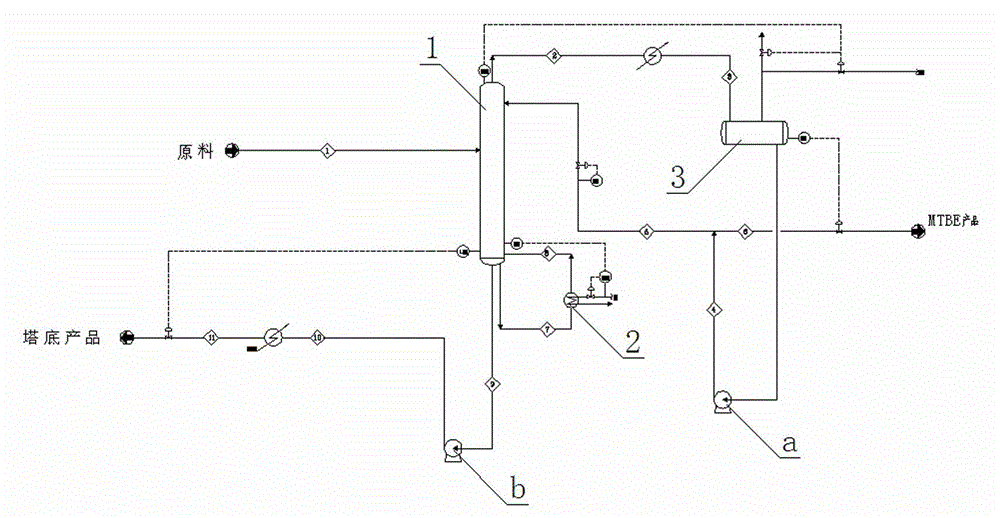

[0014] Below in conjunction with accompanying drawing, the present invention will be further described:

[0015] Rectification methyl tert-butyl ether desulfurization method, described method comprises the following steps:

[0016] The crude MTBE whose components are 98.45%~98.55% of MTBE, 0.37%~0.39% of butene, 0.38%~0.40% of carbon octane, 0.39%~0.41% of tertiary butanol and 0.02%~0.04% of sulfur compound is sent to Desulfurization tower 1, the gas phase at the top of the tower is condensed by the desulfurization tower condenser 2 and then enters the desulfurization tower reflux tank 3, and the condensate produced after condensation is boosted by pump a, and part of it is extracted as refined MTBE after the boost, and the other part is sent to the desulfurization tower The top is used as reflux; the heavy components at the bottom of the tower are taken out intermittently, boosted by pump b and cooled to 38°C~42°C as products and transported to the tank area.

[0017] The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com