Method for treating low- roxarsone waste water by efficient adsorption treatment

An adsorption treatment and low-concentration technology, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of small particle size of "alum flower", difficult to quickly separate, and consumption Large and other problems, to achieve the effect of simple preparation method, easy-to-obtain raw materials, and low-consumption treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

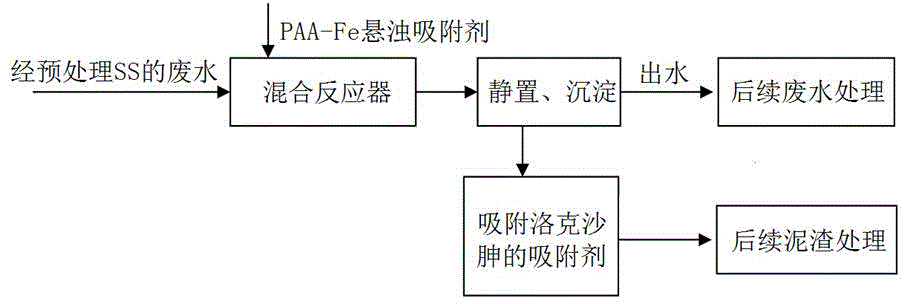

[0028] Combine figure 1 In this embodiment, a method for high-efficiency adsorption treatment of low-concentration roxarsone wastewater contains the following steps:

[0029] Step 1. Preparation of polyacrylic acid iron (Ⅲ) complex suspension adsorbent:

[0030] In the 0.2mol / L ferric nitrate (Ⅲ) solution, while stirring, add dropwise a sodium polyacrylate solution with a mass percentage concentration of 1%, where the average relative molecular weight of sodium polyacrylate contained in the sodium polyacrylate solution is greater than 10,000 Since sodium polyacrylate with a small molecular mass is easy to dissolve, this embodiment uses sodium polyacrylate with an average molecular weight greater than 10,000, which is beneficial to the formation of large-particle flocs. In this embodiment, the dropping rate of the sodium polyacrylate solution is 10 drops per minute, and the stirring speed is 300 rpm. After the complexation reaction at a temperature of 50℃ for 8h, let it stand, dis...

Embodiment 2

[0036] In this embodiment, a method for high-efficiency adsorption treatment of low-concentration roxarsone wastewater contains the following steps:

[0037] Step 1. Preparation of polyacrylic acid iron (Ⅲ) complex suspension adsorbent:

[0038] In the 0.05mol / L ferric sulfate (Ⅲ) solution, add 1% sodium polyacrylate solution with mass percentage concentration while stirring, where the average relative molecular weight of sodium polyacrylate contained in the sodium polyacrylate solution is greater than 10,000 Since sodium polyacrylate with a small molecular mass is easy to dissolve, this embodiment uses sodium polyacrylate with an average molecular weight greater than 10,000, which is beneficial to the formation of large-particle flocs. In this embodiment, the dropping rate of the sodium polyacrylate solution is 15 drops per minute, and the stirring speed is 320 rpm. After the complexation reaction at 70℃ for 6h, let it stand, discard the supernatant, wash the precipitate with dei...

Embodiment 3

[0044] In this embodiment, a method for high-efficiency adsorption treatment of low-concentration roxarsone wastewater contains the following steps:

[0045] Step 1. Preparation of polyacrylic acid iron (Ⅲ) complex suspension adsorbent:

[0046] In the 0.1mol / L ferric chloride (Ⅲ) solution, while stirring, add dropwise a sodium polyacrylate solution with a mass percentage concentration of 1%, where the average molecular weight of sodium polyacrylate contained in the sodium polyacrylate solution is greater than 10,000. Since sodium polyacrylate with a small molecular mass is easy to dissolve, this embodiment uses sodium polyacrylate with an average relative molecular mass greater than 10,000, which is conducive to the formation of large-particle flocs. In this embodiment, the dropping rate of the sodium polyacrylate solution is 20 drops per minute, and the stirring speed is 330 rpm. After the complexation reaction at 80℃ for 4 hours, let it stand, discard the supernatant, wash the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com