Explosion-proof treatment method of bared conductor of sodium cyanide cracking furnace

A processing method and technology for exposed conductors, applied in the directions of metal cyanide, simple alkali metal cyanide, etc., can solve the problems of human life and enterprise property safety threats, hidden dangers, explosions, etc., to ensure enterprise property safety, prevent explosions, The effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below according to accompanying drawing:

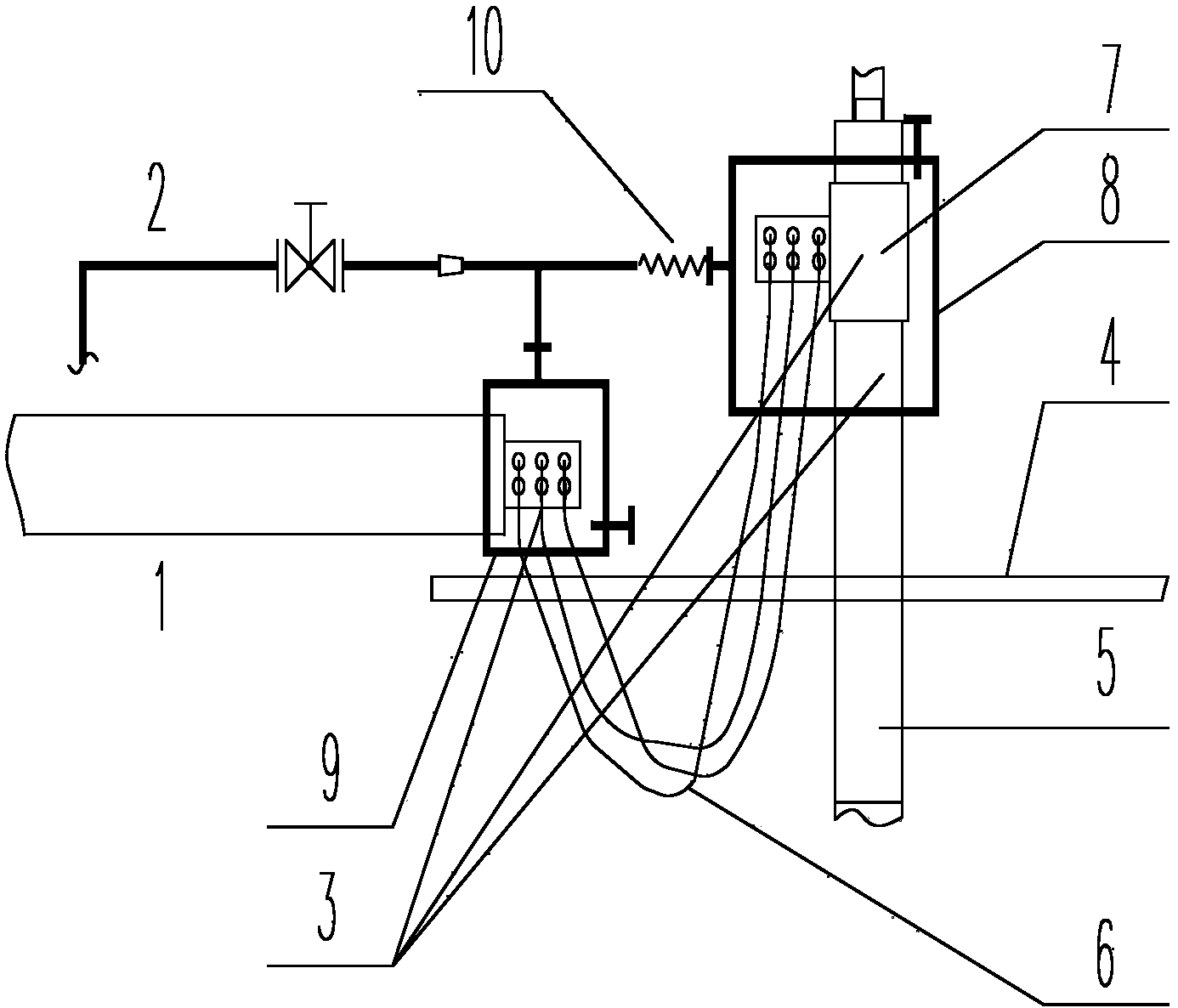

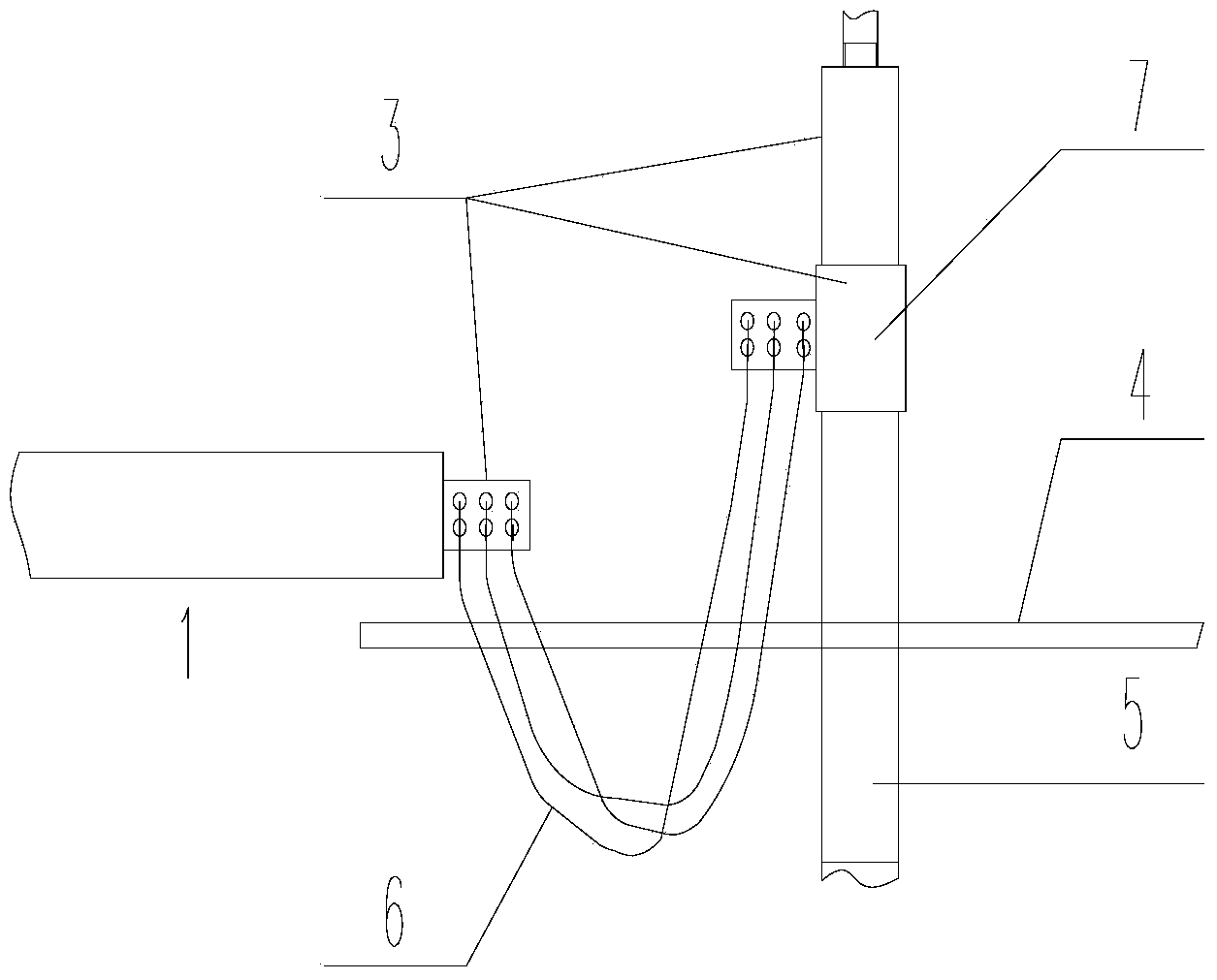

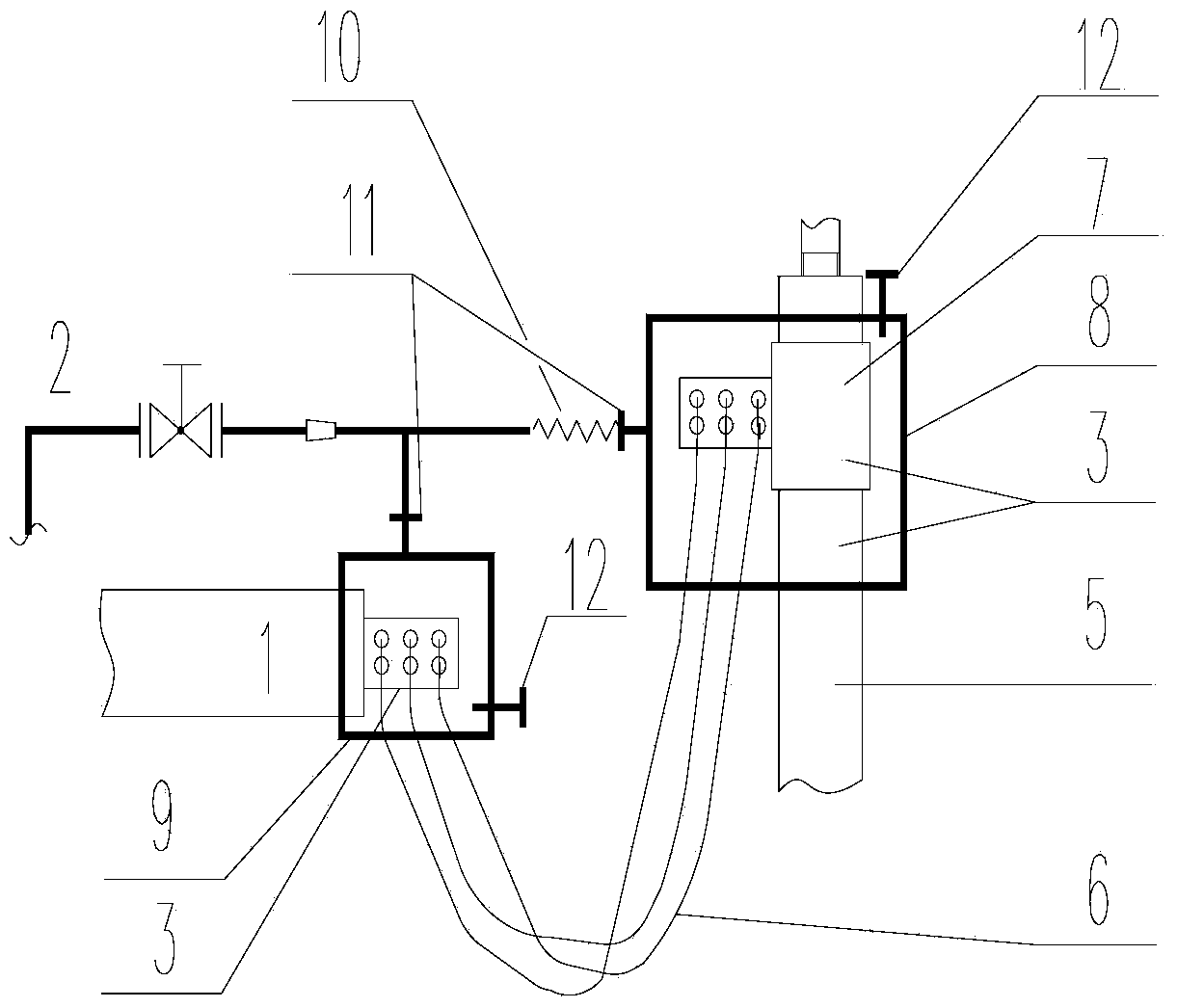

[0021] as attached figure 2 As shown, in the production process of sodium cyanide by the light oil cracking method, the light oil cracking furnace and its related facilities are located in the explosion-proof area. The exposed live conductors 3, such as the connection between the cable and the electrode conductive hoop, and the junction of the electrode hoop and the electrode rod, are extremely dangerous if no measures are taken. as attached figure 1 , attached image 3 As shown, the present invention intends to use non-metallic insulating materials to make two protective boxes (8 and 9) for protection, and then pass nitrogen gas into the protective box through the nitrogen main pipe 2: the pressure of the nitrogen gas source is 0.05-0.15MPaG, and the pipe diameter of the main pipe is 15mm to 32mm, and the pipe diameter becomes smaller near the blowing point to incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com