High-frequency small-load mechanical hydraulic compound transmission press machine

A mechanical hydraulic and compound transmission technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of ineffective acceleration of hydraulic cylinders, increased costs of pipelines and connectors, and inability to achieve various processing techniques. To achieve the effects of compact structure, low manufacturing and maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

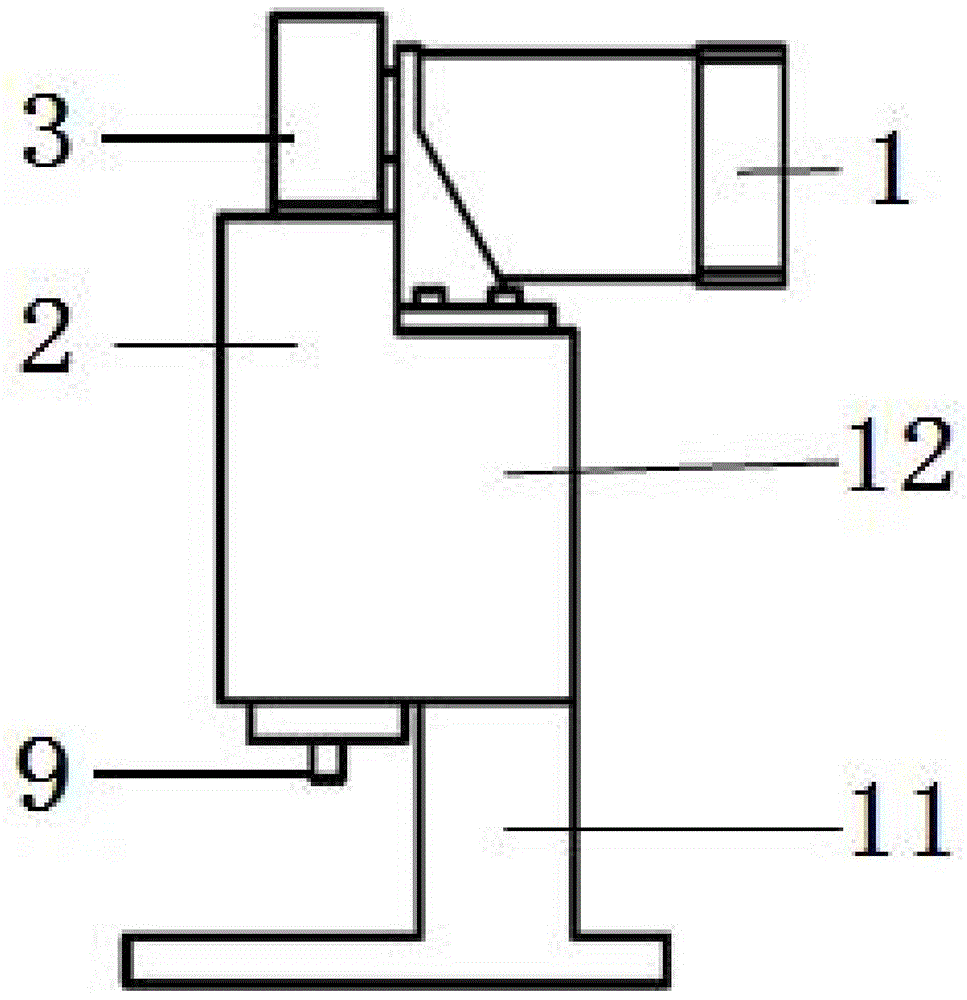

[0021] Example: Combined Figure 1~Figure 4 As shown, the high-frequency and small-load mechanical-hydraulic compound transmission press provided by the present invention consists of a servo rotary motor 1, a hydraulic cylinder 2, a form-closed eccentric mechanism 3, a piston 8, a return spring (not visible in the figure), Piston rod 9, machine tool base 11 and machine tool support frame 12 are jointly formed.

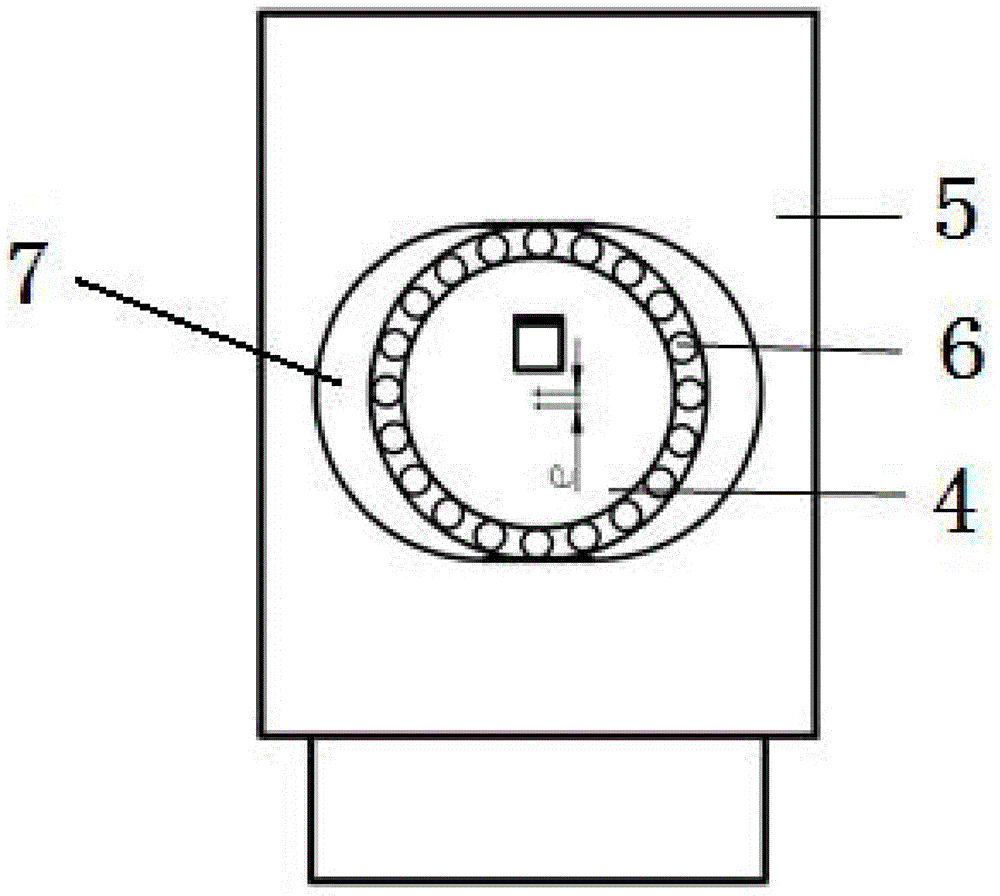

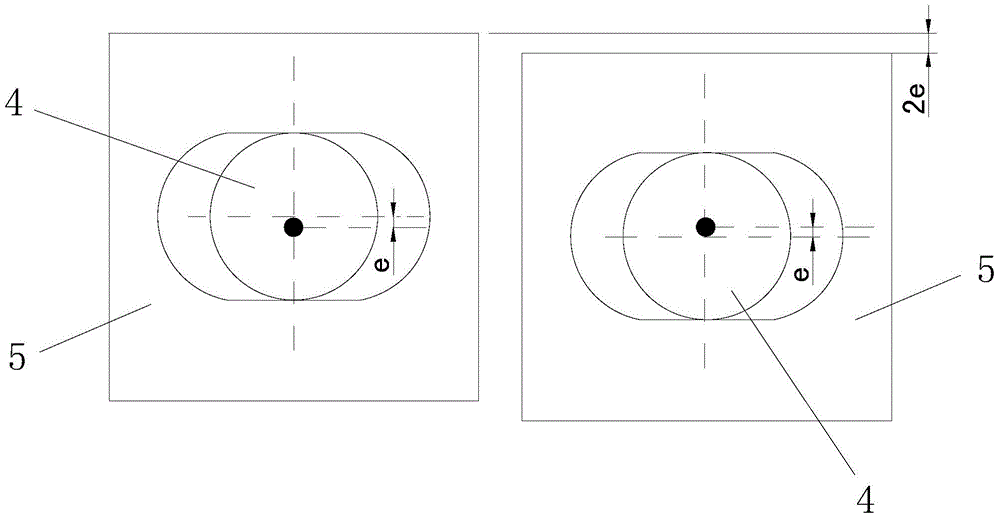

[0022] In this embodiment, the machine tool support frame 12 is fixed on the machine tool base 11 , the servo rotary motor 1 is fixed on the machine tool support frame 12 , and the hydraulic cylinder 2 is integrally connected to one side of the machine tool support frame 12 . The mechanism in this embodiment is composed of an eccentric rotating member 4 , a form closure 5 and a bearing 6 . The eccentric rotating member 4 in this embodiment is an eccentric bushing, which is sleeved and fixed on the output shaft (not shown in the figure) of the servo rotary motor 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com