Improved energy-storage impact-type pneumatic wrench

An impact-type, air-trigger technology, applied in power tools, manufacturing tools, etc., can solve the problems of affecting the impact kinetic energy, weakening the output torque of the gas trigger, and reducing the output power of the pneumatic motor, so as to improve the impact energy and output torque, and improve labor. Productivity, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

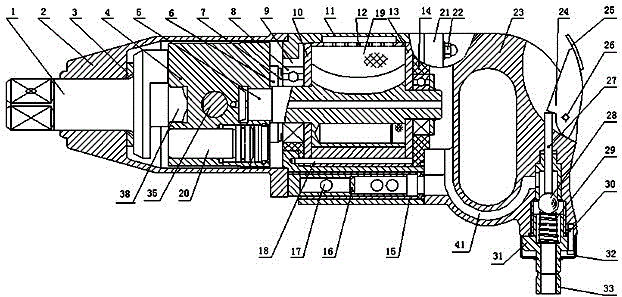

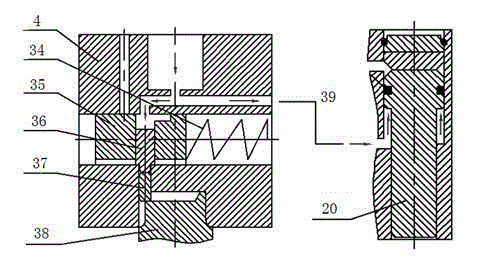

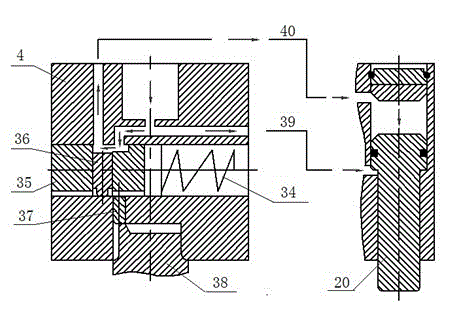

[0021] Embodiment 1: as attached figure 1 As shown, the air inlet joint 33 is installed on the tail end of the handle 23 through the air valve 31, and the anti-loosening lock pin 30 parallel to the air intake direction is installed on the periphery connecting the air valve 31 and the tail end of the handle 23, and the middle shell 11 is installed in front of the handle 23 , the cylinder 12 is installed in the middle shell 11, the rotor 5 of the central axis and the blade 19 on its outer edge are installed in the cylinder 12, and the direction control valve 15 is installed inside the side wall of the middle shell 11; the handle 23 has an air guide The cavity 41 communicates with the air valve 31, the direction control valve 15 and the inner hole of the central shaft of the rotor 5; at the same time, the front of the middle shell 11 is connected to the front shell 2, and the hammer body 4 is installed in the rear of the front shell 2, and the centrifugal valve 35 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com