Welding method for multistage circular welds of medium and thin wall variable-diameter aluminum alloy shell

A welding method and technology of aluminum alloy, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as failure to meet product use requirements, low quality of shell welds, overall deformation of the shell, etc., to reduce welding defects The probability of occurrence, the effect of improving preheating and welding efficiency, reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

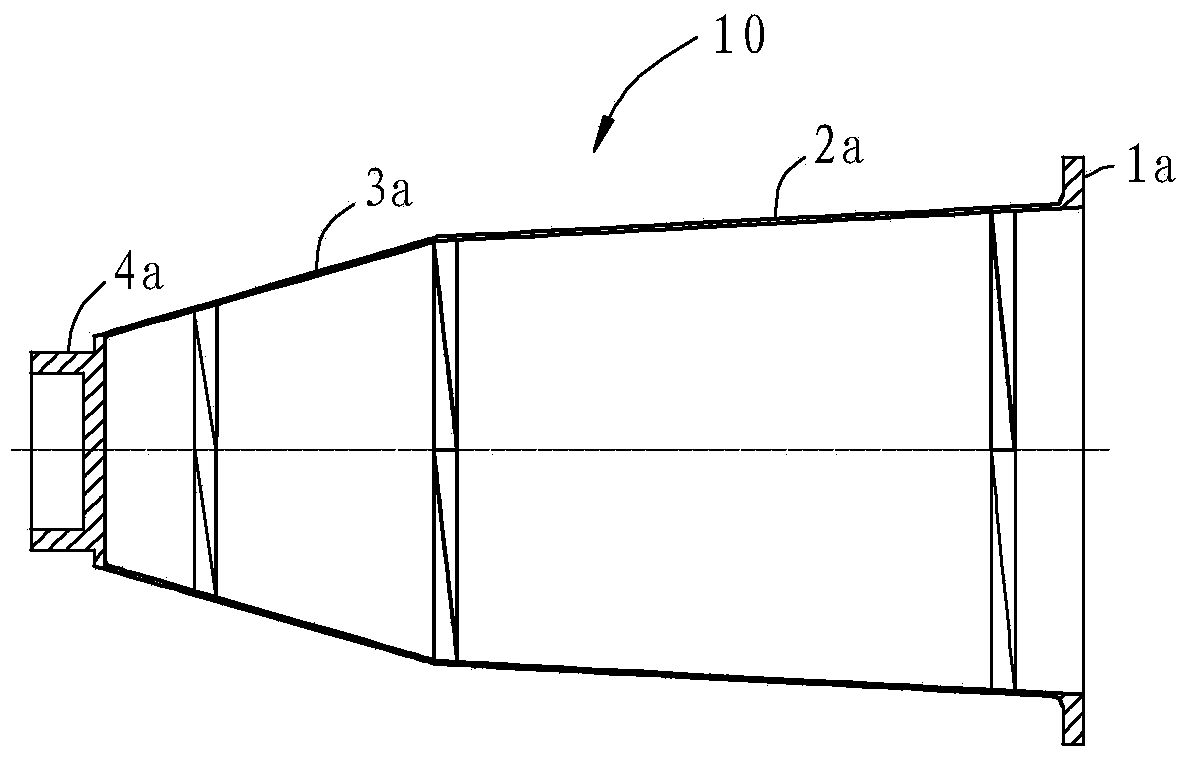

[0041] Example 1, such as figure 1 As shown, the aluminum alloy shell in this embodiment includes a first sleeve 2a and a second sleeve 3a welded to each other in sequence, the inner diameter of the first sleeve 2a is larger than the inner diameter of the second sleeve 3a, and the outer diameter of the first sleeve 2a The end is welded with a large flange 1a, and the outer end of the second sleeve 3a is welded with a small flange 4a.

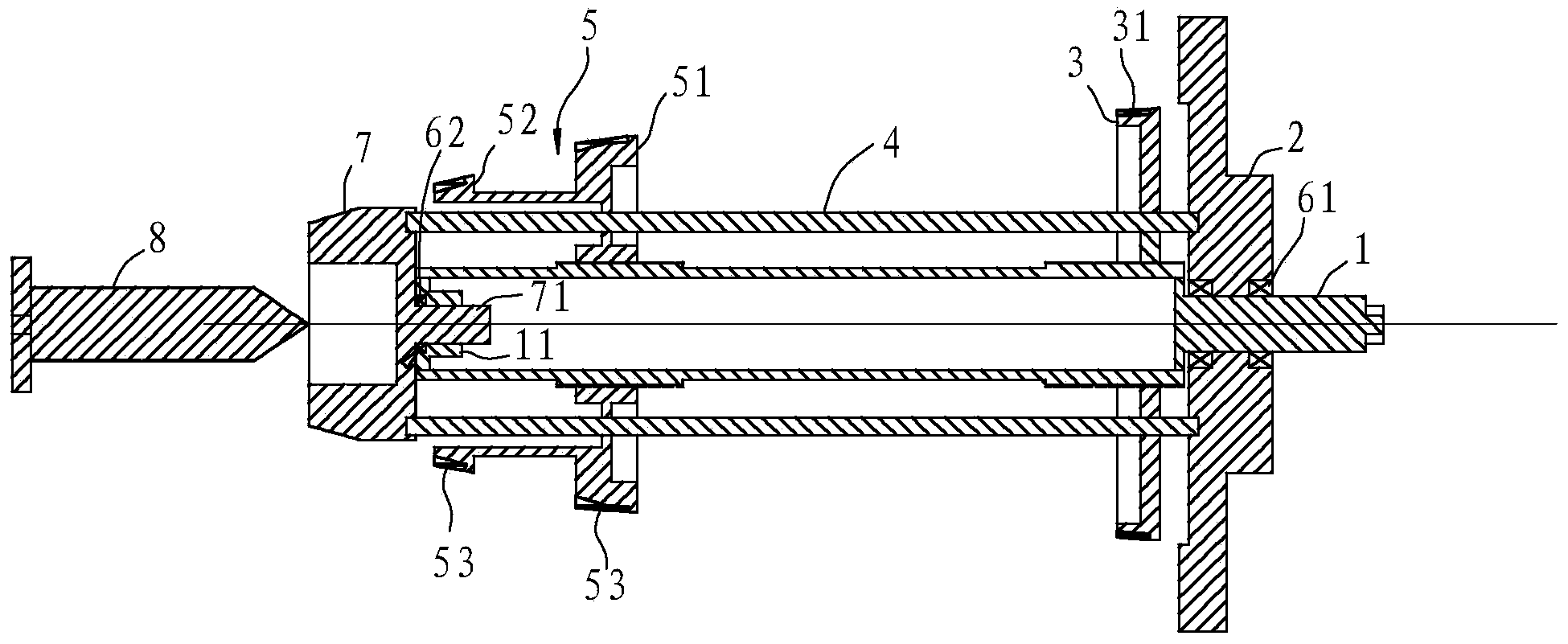

[0042] Such as figure 2 As shown, the welding tool in this embodiment includes a mandrel 1 , a first positioning seat 2 , a second positioning seat 7 , a tie rod 4 , a large-end support seat 3 , a middle-end support seat 5 and a clamping block 8 .

[0043] The first positioning seat 2 is arranged on the mandrel and can rotate around the mandrel 1, and is used for positioning the large flange 1a, and the second positioning seat 7 is arranged at intervals with the first positioning seat 2, and is used for positioning the small flange 4a; the pul...

Embodiment 2

[0054] Embodiment 2. In this embodiment, a 7A05 aluminum alloy variable-diameter shell with a wall thickness of 4.0 mm and four-stage girth welds is welded. It includes the following steps:

[0055] (1) Welding joint design and welding method design: Welding joints are determined not to open grooves, and single-sided welding and double-sided forming are adopted by welding processes such as variable polarity. The welding seam assembly gap is set to 0mm, the welding gun does not move, and the shell rotates. (2) Cleaning: acid-base cleaning of large, medium, small tubes and flanges of aluminum alloy shells that need to be welded; (3) Assembly: place the porcelain lining blocks on the four-stage mobile support Seat, then assemble and position the shell parts on the special welding tool at one time, and adjust the mandrel to support the shell from the inside; (4) Secondary cleaning: use dry compressed air to blow the four-stage weld to be welded before welding (5) Preheating: no p...

Embodiment 3

[0056] Embodiment 3. In this embodiment, a 5A06 aluminum alloy variable-diameter shell with a wall thickness of 12.0 mm and three-stage girth welds is welded. It includes the following steps:

[0057] (1) Welding joint design and welding method design: Welding joints are determined to open a 30° groove, adopt welding processes such as polarity change, single-sided welding and double-sided molding, set the welding seam assembly gap to 0mm ~ 1.0mm, and the welding torch does not move. Preheating and welding of the shell rotation; (2) Cleaning: acid-base cleaning of the large and small aluminum alloy shells and flanges that need to be welded; (3) Assembly: place the porcelain lining blocks on the three-stage mobile support Seat, then assemble and position the shell parts on the special welding tool at one time, and adjust the mandrel to prop up the shell from the inside; (4) Secondary cleaning: before welding, use dry compressed air to blow the tertiary weld to be welded ; (5) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com