Multi-furnace casting method for aluminum ingot and chute assembly and casting equipment for implementing the method

A chute and assembly technology, which is applied to the multi-furnace casting of aluminum ingots and the field of implementing the chute assembly and casting equipment, can solve the problems of difficulty in meeting the needs of mixing furnaces to enter molten aluminum, affecting the production efficiency of aluminum ingots, and trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

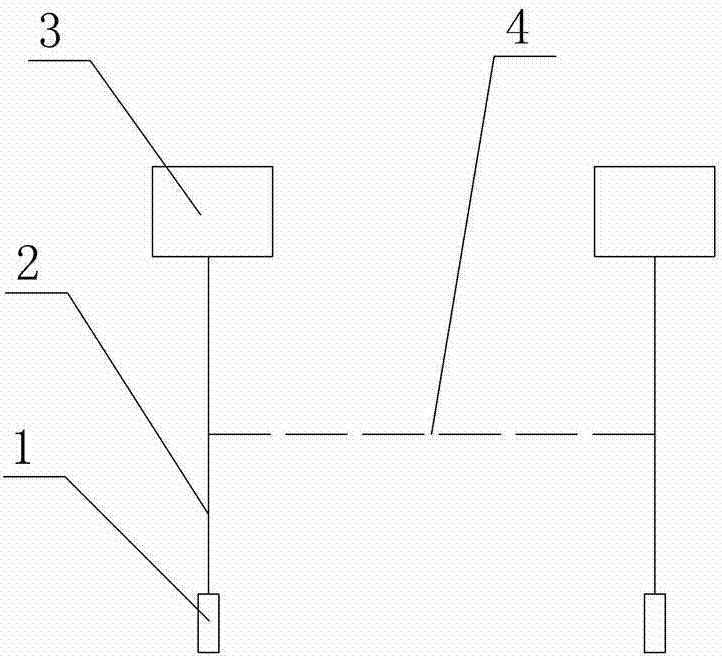

[0016] An embodiment of casting equipment of the present invention: as Figure 1-3 As shown, it includes a mixing furnace 3, a chute assembly and a casting production line 1, wherein there are two mixing furnaces 3 and two casting production lines 1 corresponding to each mixing furnace 3 one by one. The chute assembly includes the main chute 2 respectively connected between the furnace eye of the corresponding mixing furnace 3 and the casting production line 1, the branch chute 4 is connected between the two main chute 2, and the connection between the main chute 2 and the branch chute 4 is provided with The diversion structure, the diversion structure is the diversion refractory brick 5 fixed in the main chute 2; the bottom of the branch chute 4 is supported with support frames 6 arranged at intervals along the length direction of the branch chute, and the support frame is provided with adjustable self-height The adjustable support structure can adjust the slope of the branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com