Method for extracting angiotensin I invertase inhibitor from camellia sinensis fruit peel

An angiotensin and tea peel technology, which is applied in the field of extracting angiotensin Ⅰ converting enzyme inhibitors from tea peels, achieves a significant inhibitory effect and improves economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

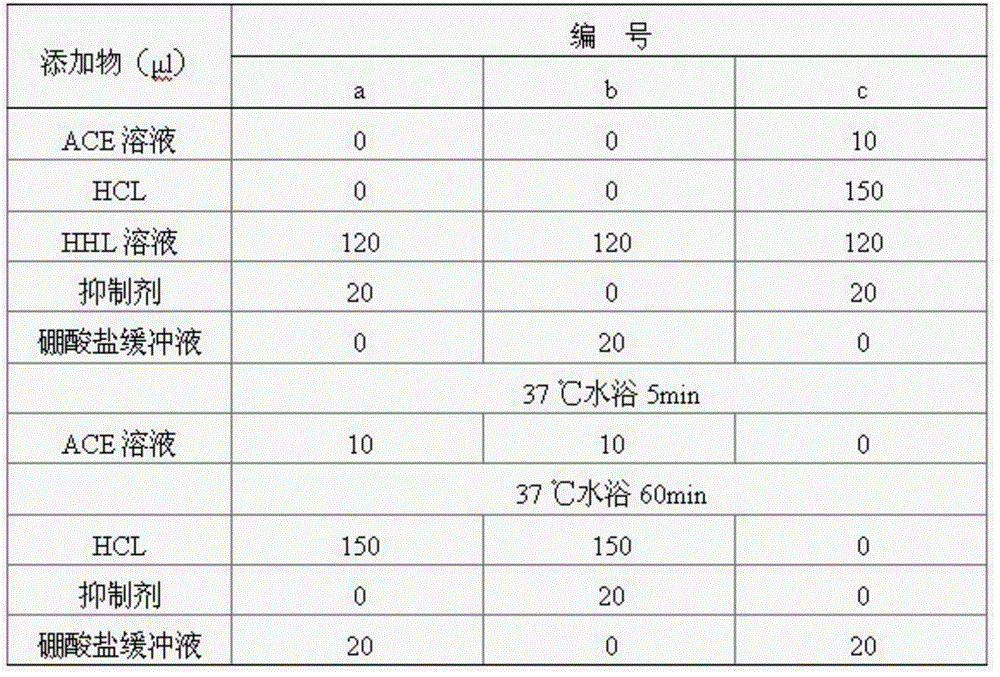

Method used

Image

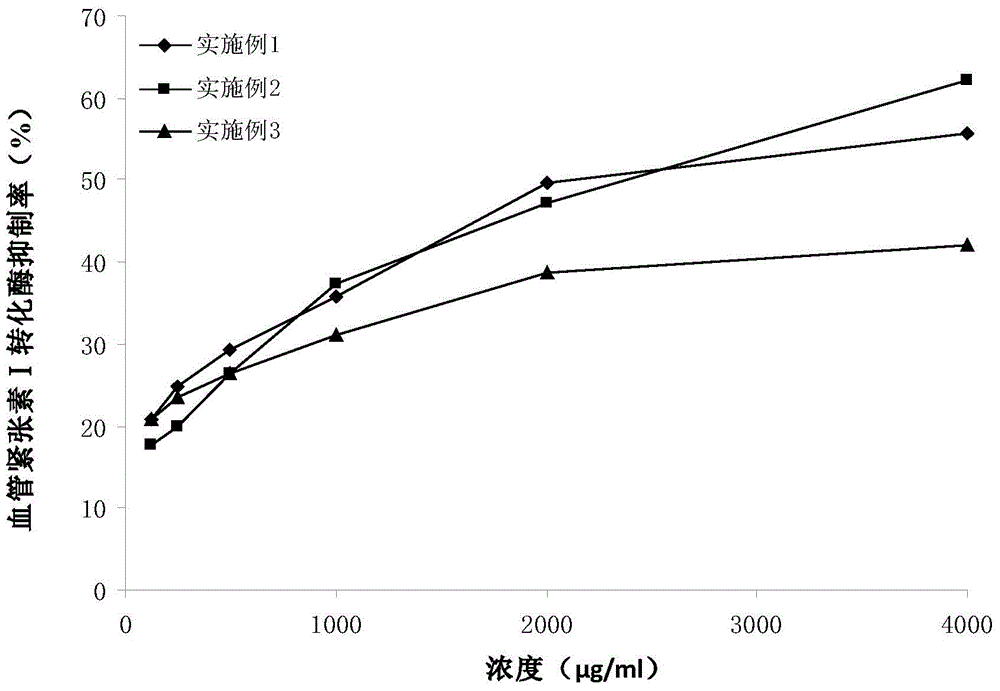

Examples

Embodiment 1

[0028] Step A: Weigh 20 g of the dried and pulverized tea peel, take the tea peel and acetone as a ratio of 1 g: 10 ml, add acetone to the tea peel, soak for 4 hours and then centrifuge to obtain the tea peel. The centrifugation condition is: 5000 rpm minutes, centrifuged for 10 minutes;

[0029] Step B: Add a buffer solution with a pH of 2 to the acetone-soaked tea peel obtained in step A at a ratio of 1 g: 15 ml to the tea peel and buffer solution, and perform ultrasonic extraction at a frequency of 200 W for 2 hours and then centrifuge to obtain the extracted solution; the buffer is preferably disodium hydrogen phosphate-citric acid buffer, and the centrifugation condition is: 5000 rpm, centrifuged for 10 minutes;

[0030] Step C: adding chloroform to the extract obtained in step B at a volume ratio of 1:1 between the extract obtained in step B and chloroform to obtain a raffinate;

[0031] Step D: Concentrating the raffinate obtained in step C and then freeze-drying to ob...

Embodiment 2

[0035] Step A: Weigh 20 g of the dried and pulverized tea peel, take the tea peel and acetone as the ratio of 1g:15ml, add acetone to the tea peel, soak for 3.5 hours and then centrifuge to obtain the tea peel. The centrifugation condition is: 5000 rpm minutes, centrifuged for 10 minutes;

[0036] Step B: Add a buffer solution with a pH of 2.5 to the acetone-soaked tea peel obtained in step A at a ratio of 1g:20ml to the tea peel and buffer solution, and perform ultrasonic extraction at a frequency of 250W for 1.5 hours and then centrifuge to obtain the extracted solution; the disodium hydrogen phosphate-citric acid buffer solution, the centrifugation condition is: 5000 rpm, centrifuged for 10 minutes;

[0037] Step C: adding chloroform to the extract obtained in step B at a volume ratio of 2:1 between the extract obtained in step B and chloroform to obtain a raffinate;

[0038] Step D: Concentrating the raffinate obtained in step C and then freeze-drying to obtain the primar...

Embodiment 3

[0042] Step A: Weigh 20 g of the dried and pulverized tea peel, take the tea peel and acetone as the ratio of 1g:20ml, add acetone to the tea peel, soak for 3 hours and then centrifuge to obtain the tea peel. The centrifugation condition is: 5000 rpm minutes, centrifuged for 10 minutes;

[0043] Step B: Add a buffer solution with a pH of 3 to the acetone-soaked tea peel obtained in step A at a ratio of 1 g: 25 ml to the tea peel and buffer solution, and perform ultrasonic extraction at a frequency of 300 W for 1 hour and then centrifuge to obtain the extracted solution; the buffer is preferably disodium hydrogen phosphate-citric acid buffer, and the centrifugation condition is: 5000 rpm, centrifuged for 10 minutes;

[0044] Step C: adding chloroform to the extract obtained in step B at a volume ratio of 3:1 between the extract obtained in step B and chloroform, and extracting to obtain a raffinate;

[0045]Step D: Concentrating the raffinate obtained in step C and then freeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com