Curing agent for curing meat product and method for curing preserved meat

A technology for pickling preparations and meat products, which is applied in the field of pickling preparations for cured bacon and cured meat products. It can solve the problems of fat oxidation, hygiene and toxin residues, and extensive operation methods, so as to achieve safe shelf life and improve moisture content. The effect of simple content and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

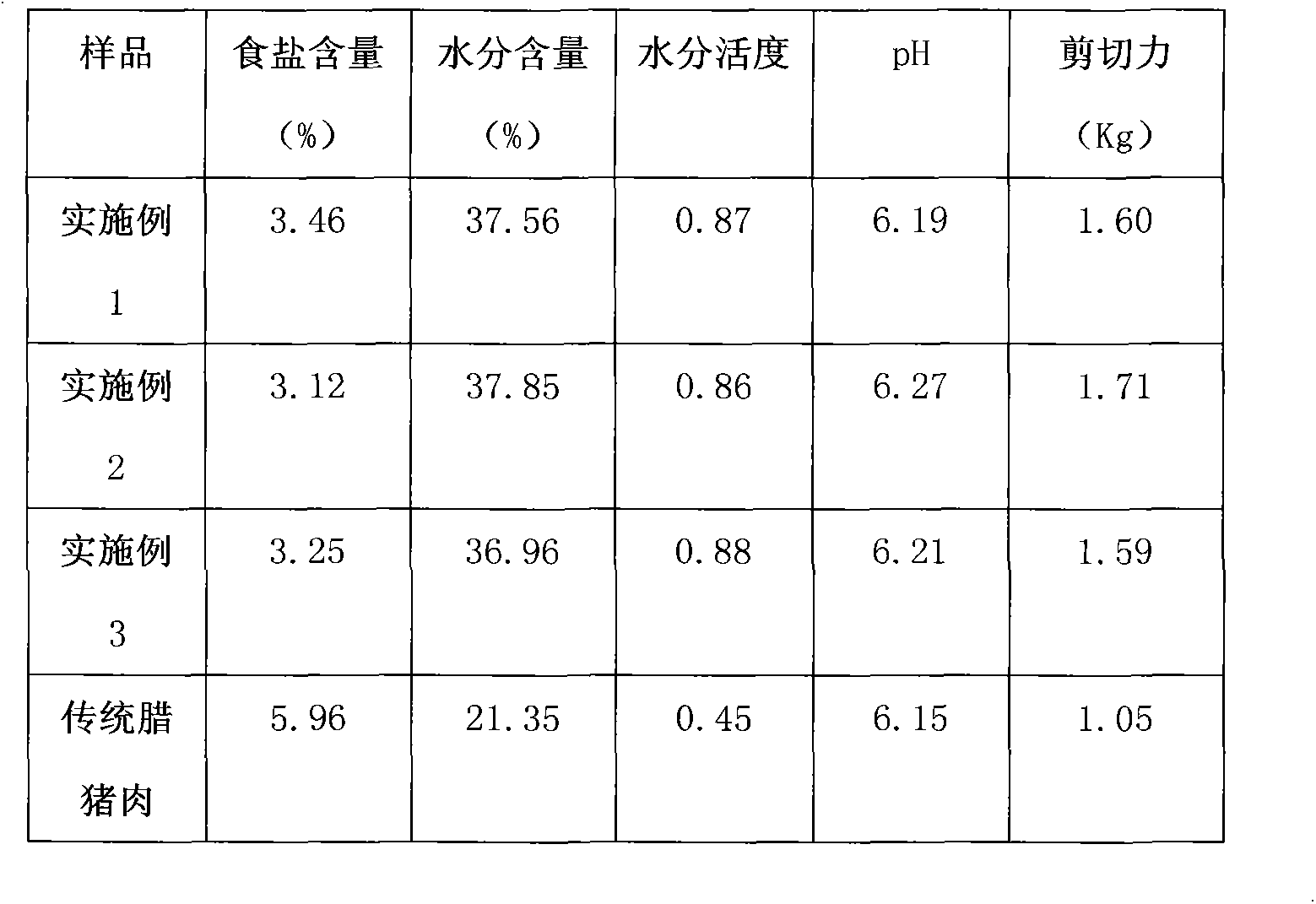

Examples

Embodiment 1

[0086] Marinade Recipe 1

[0087] 2.5kg of table salt, 3.5kg of white sugar, 2kg of koji wine, 3kg of colorless soy sauce, 0.5kg of compound phosphate, 0.03kg of tea polyphenols, 0.006kg of sodium nitrite, 0.05kg of sodium erythorbate, 50g of Ni sin, 1000ml of potassium lactate, spices 400g.

[0088] Each raw material is weighed in the pickling preparation formula 1, is used for pickling raw pork 100kg.

[0089] Process 1: Raw meat→cut into strips of about 25×10cm→weigh (200g)→add marinade→tumble and marinate in a tumbler (4°C 50min)→place in a marinating tank for marinating Preparation (marinated at 4°C for 72 hours)→washing in water at 40°C (removing surface oil and sundries, etc.)→drying the surface moisture at room temperature→baking and drying in a drying room (baking at 50°C for 30h)→smoke (Smoking at 60°C for 4 hours)→Close the flue→Dry to finished product→Shut down and cool down→Cool→Vacuum pack with PE / Ny composite packaging film (35cm×15cm).

Embodiment 2

[0091] Marinade Recipe 2

[0092] Salt 2.0kg, white sugar 2.5kg, koji wine 1kg, colorless soy sauce 4kg, compound phosphate 0.2kg, tea polyphenols 0.01kg, sodium nitrite 0.01kg, sodium erythorbate 0.025kg, Nisin 25g, potassium lactate 500ml, spices 800g .

[0093] Each raw material in the marinade formula 2 is weighed, and is used for marinating raw beef 100kg.

[0094] Process 2: Raw meat → cut into strips of about 25×10cm → weigh (200g) → add pickling agent → knead and marinate in a tumbler (4°C 35min) → place in a marinating tank for marinating Preparing (marinating at 4°C for 70 hours) → washing in water at 40°C (removing surface oil and sundries, etc.) → drying surface moisture at room temperature → drying in a drying room (baking at 52°C for 28 hours) → smoking (Smoking at 60°C for 2 hours)→Close the flue→Dry to finished product→Shut down and cool down→Cool→Vacuum pack with PE / Ny composite packaging film (35cm×15cm).

Embodiment 3

[0096] Marinade Recipe 3

[0097] Salt 3.0kg, white sugar 4.5kg, koji wine 3kg, colorless soy sauce 1kg, compound phosphate 0.3kg, tea polyphenols 0.05kg, sodium nitrite 0.012kg, sodium erythorbate 0.01kg, Ni sin 10g, potassium lactate 1200ml, spices 200g.

[0098] Each raw material in the marinade formula 2 is weighed, and is used for marinating raw chicken 100kg.

[0099] Process 3: Raw meat→cut into strips of about 25×10cm→weigh (200g)→add marinade→tumble and marinate in a tumbler (4°C 65min)→place in a marinating tank for marinating Preparation (marinate at 4°C for 74h) → wash in water at 40°C (remove surface oil, sundries, etc.) → dry the surface moisture at room temperature → bake and dry in a drying room (bake at 54°C for 32h) → smoke (Smoking at 60°C for 6 hours)→Close the flue→Dry to finished product→Shut down and cool down→Cool→Vacuum pack with PE / Ny composite packaging film (35cm×15cm).

[0100] In the above example:

[0101] Table salt (first grade): Refined sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com