Mushroom bed feeder

A material machine and mushroom bed technology, which is applied in the field of mushroom bed material machine, can solve the problems of time-consuming and labor-consuming, uneven loading, complicated loading process, etc., so as to facilitate growth, increase the feeding speed of mushroom bed, and flexibly control convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

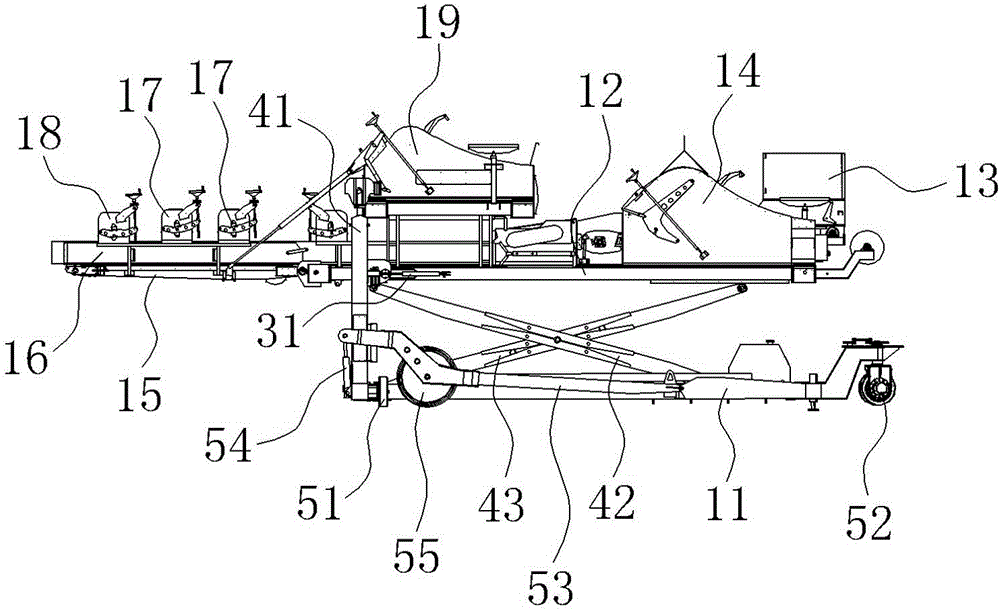

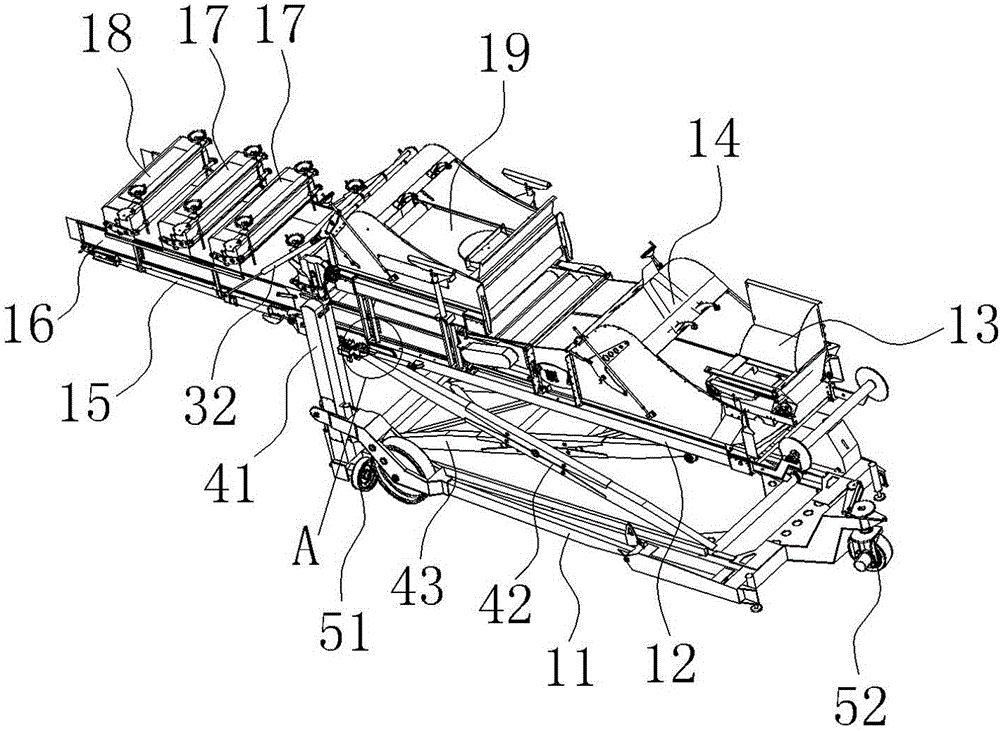

[0026] Such as figure 1 and figure 2 The mushroom bed feeder shown includes a mobile frame 11, a workbench 12 located above the mobile frame 11, and a lifting structure for driving the workbench 12 to lift between the mobile frame 11 and the workbench 12. The workbench 12 is provided with a conveyor belt, and the workbench 12 is sequentially provided with an upper hopper 13 and a leveling unit 14 located above the conveyor belt along the conveying direction of the conveyor belt.

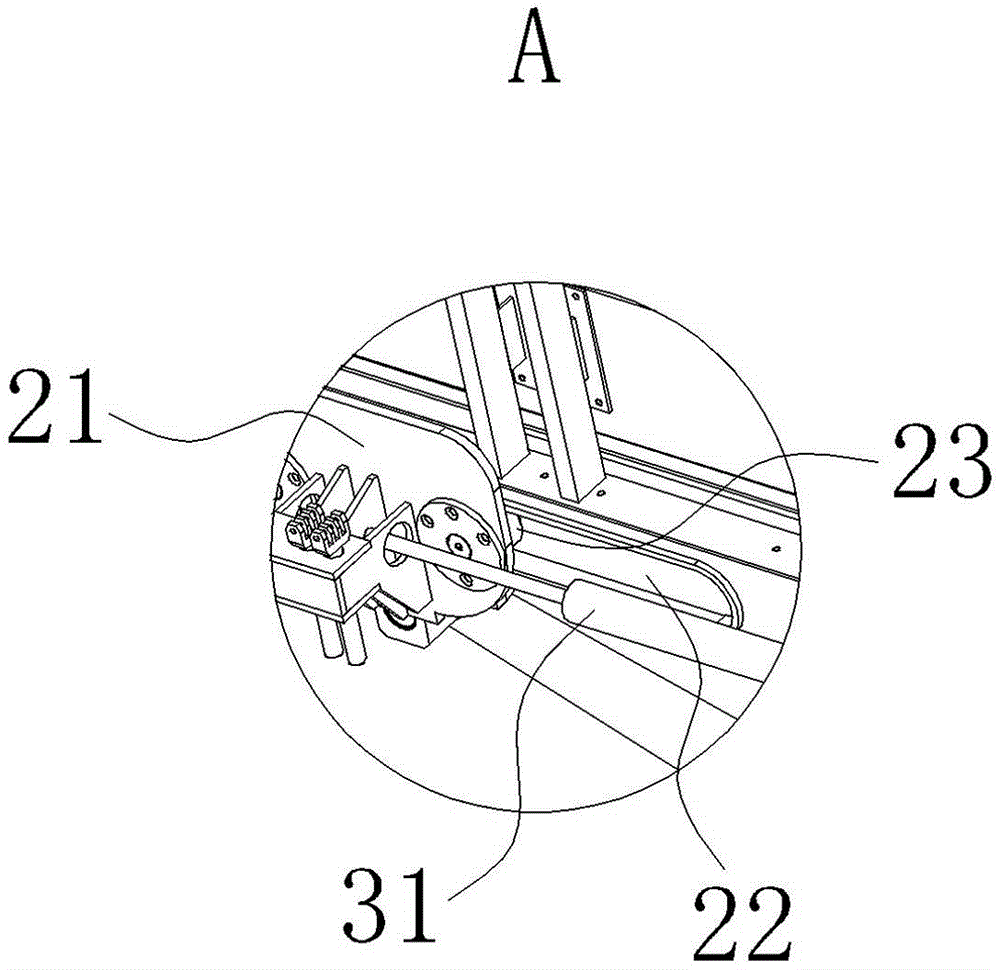

[0027] Specifically, such as figure 1 As shown, the lifting structure includes a jacking cylinder 41 vertically arranged on the mobile frame 11 , and the piston rod of the jacking cylinder 41 is fixedly connected with the workbench 12 . Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com