Method for preparing Si/Ag/C composite negative material based on silver mirror reaction principle

A negative electrode material and silver mirror reaction technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low conductivity and unfavorable battery rate performance, and achieve uniform distribution, good rate performance and excellent cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

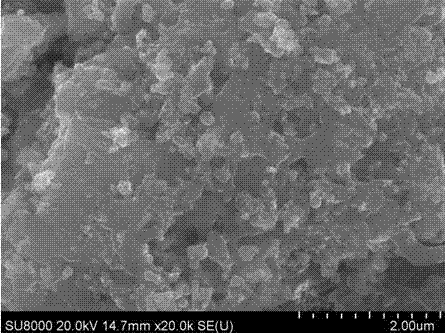

[0025] like figure 1 As shown, the concentration of 5% silver nitrate solution is dropped into the concentration of 20% ammonia solution to form a concentration of 2% silver ammonia solution; silicon powder with a size of 20nm is n Si : n Ag =50:1 ratio into the silver ammonia solution, adjust the pH value of the solution to 8; then the concentration is 25% glucose solution with n 葡萄糖 : n Ag =1:1 ratio slowly drop into the above solution, at 100 o C under magnetic stirring until the precursor body is formed; the precursor body is put into a tube furnace with argon gas for sintering, and the heating rate is controlled to be 10 o C / min, sintering temperature is 725 o C. The sintering time is 3 hours; finally, the temperature is lowered by cooling with the furnace, and the Si / Ag / C composite negative electrode material can be obtained.

Embodiment 2

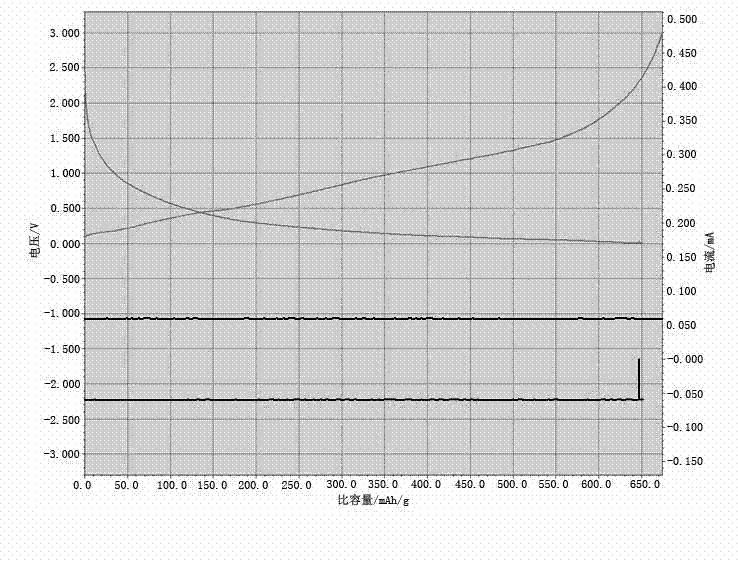

[0027] like figure 2 As shown, the concentration of 2% silver nitrate solution is dropped into the concentration of 32% ammonia solution to form a concentration of 5% silver ammonia solution; silicon powder with a size of 320nm is n Si : n Ag =62:1 ratio was added to the silver ammonia solution to adjust the pH value of the solution to 9.5; then the concentration was 38% glucose solution with n 葡萄糖 : n Ag =1.5:1 ratio slowly drop into the above solution, at 95 o C under magnetic stirring until the precursor body is formed; the precursor body is put into a tube furnace with argon gas for sintering, and the heating rate is controlled to be 20 o C / min, sintering temperature is 550 o C. The sintering time is 10 hours; finally, the temperature is lowered by cooling with the furnace, and the Si / Ag / C composite negative electrode material can be obtained.

Embodiment 3

[0029] Drop the concentration of 4% silver nitrate solution into the concentration of 10% ammonia solution to form a concentration of 11% silver ammonia solution; n Si : n Ag =80:1 ratio was added to the silver ammonia solution to adjust the pH value of the solution to 9; then the concentration was 45% of the glucose solution to n 葡萄糖 : n Ag =1.2:1 ratio slowly drop into the above solution, at 80 o C under magnetic stirring until the precursor body is formed; the precursor body is put into a tube furnace with argon gas for sintering, and the heating rate is controlled to be 15 o C / min, sintering temperature is 600 o C. The sintering time is 8 hours; finally, the temperature is lowered by cooling with the furnace, and the Si / Ag / C composite negative electrode material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com