Low-cost high-integrated flexible ultrathin ultralight supercapacitor

A supercapacitor, a low-cost technology, applied in the manufacture of hybrid capacitor separators, hybrid/electric double layer capacitors, etc., can solve the problems of degraded energy storage and cycle stability, complicated preparation process and process, and poor electrochemical performance , to achieve long life and work stability, clear appearance, and improve mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

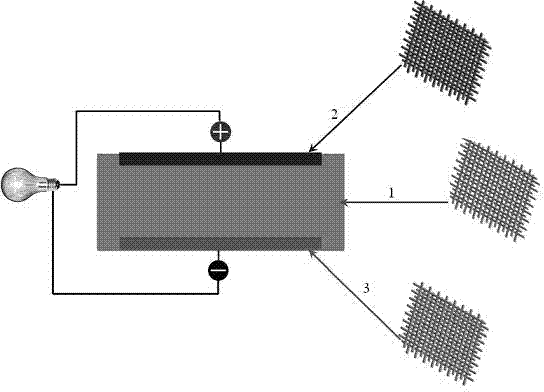

[0033] Example 1 The preparation method of this supercapacitor comprises the following steps:

[0034] (1) Preparation of polymer solution: Dissolve 1 g of polymer in 9 g of N, N dimethylformamide solvent and stir at room temperature for 2 hours to obtain a transparent and clear polymer solution.

[0035] Wherein: the polymer refers to polyacrylonitrile.

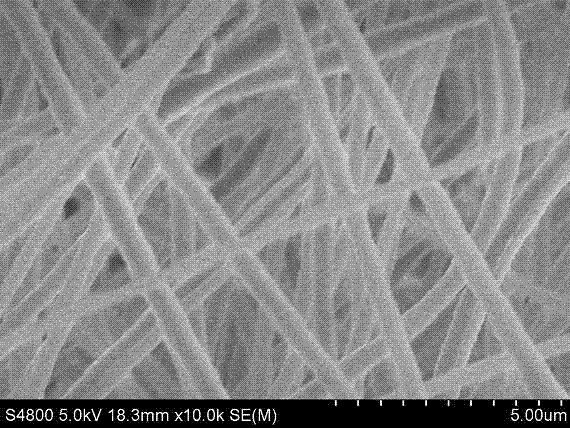

[0036] (2) Preparation of polymer nanofiber separator 1:

[0037] Put the polymer solution into a syringe with a spinneret, and form a strong electric field by applying a high voltage of 10~30kV between the spinneret and the collecting plate. At this time, the jet stream is accelerated and pulled under the action of the strong electric field. The continuous reduction is accompanied by the volatilization of the solvent and the solidification of the fibers, and finally a polymer nanofiber membrane 1 with a thickness of 40-150 μm is obtained on the collecting plate.

[0038] Wherein: the distance between the spinneret a...

Embodiment 2

[0043] Example 2 The preparation method of this supercapacitor comprises the following steps:

[0044] ⑴ Prepare the polymer solution with Example 1 . Wherein: polymer refers to polyacrylic acid.

[0045] ⑵Preparation of polymer nanofiber separator 1 with Example 1 .

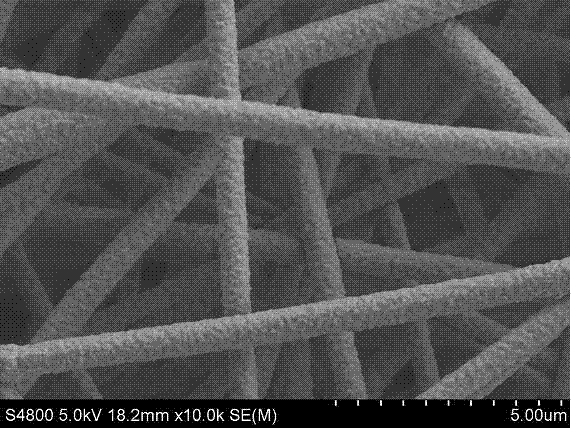

[0046] (3) Use the magnetron sputtering method to form a metal conductive layer with a thickness of 200-400nm on the positive and negative sides of the polymer nanofiber diaphragm 1 facing each other, and then immerse the polymer nanofiber diaphragm 1 at a concentration of The 0.02M aqueous solution or metal salt solution containing electroactive substances is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturated calomel is used as the reference electrode, and the electrochemical workstation is used to provide 0~1.0V between the working electrode and the counter electrode After depositing the electroactive material on the metal conductive layer to f...

Embodiment 3

[0050] Example 3 The preparation method of this supercapacitor comprises the following steps:

[0051] ⑴ Prepare the polymer solution with Example 1 . Wherein: polymer refers to polyethylene glycol.

[0052] ⑵Preparation of polymer nanofiber separator 1 with Example 1 .

[0053] (3) Use the method of magnetron sputtering to form a metal conductive layer with a thickness of 400-600 nm on the positive and negative sides of the polymer nanofiber diaphragm 1 facing each other, and then immerse the polymer nanofiber diaphragm 1 at a concentration of The 0.03M aqueous solution or metal salt solution containing electroactive substances is used as the working electrode, the platinum electrode is used as the counter electrode, and saturated calomel is used as the reference electrode, and the electrochemical workstation is used to provide 0~1.0V between the working electrode and the counter electrode After depositing the electroactive material on the metal conductive layer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com