A manufacturing process of an air filter intake pipe

An air filter and manufacturing process technology, applied in the direction of combustion air/combustion-air treatment, machine/engine, engine components, etc., can solve the problems of many processes, long production cycle, complex process, etc., to improve work efficiency, The effect of reducing production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

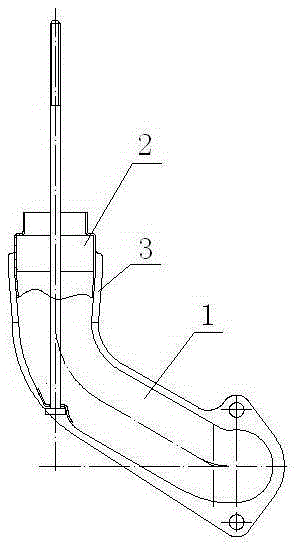

[0016] This embodiment provides an air filter intake pipe, including an intake elbow 1 and a sleeve 2, the sleeve 2 is arranged at the connection end between the intake elbow 1 and the air filter, the sleeve 2 and The intake elbow 1 is integral, and the sleeve 2 is the stamped and stretched part 3 of the intake elbow 1 .

[0017] This embodiment also provides a manufacturing process of an air filter intake pipe, including the following steps.

[0018] 1) Step 1: Cut the 0.8~1.5mm thick cold-rolled steel plate to the required size.

[0019] 2) Step 2, place the cut cold-rolled steel plate in the mould, and position it with positioning pins. The mold includes a punch and a die that cooperate with each other. The forming area of the corresponding groove has a groove, and a movable ejector pin is set in the groove; the extrusion surface of the punch has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com