Drill rod buffer positioning device of hydraulic rock drill

A technology of hydraulic rock drill and buffer device, which is applied to the driving device of rotary combined drilling, impact drilling, reciprocating drilling rig, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

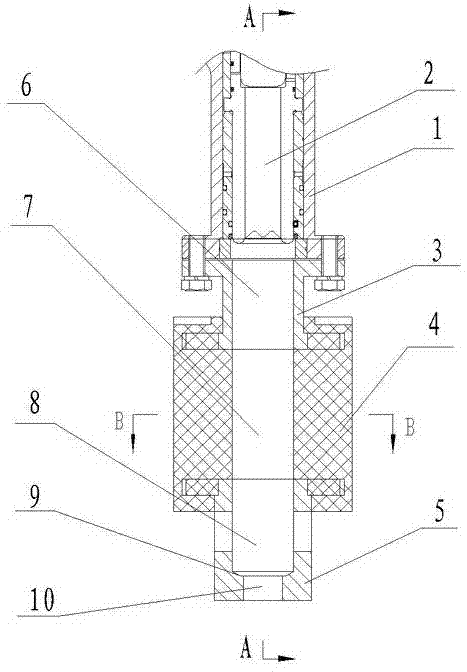

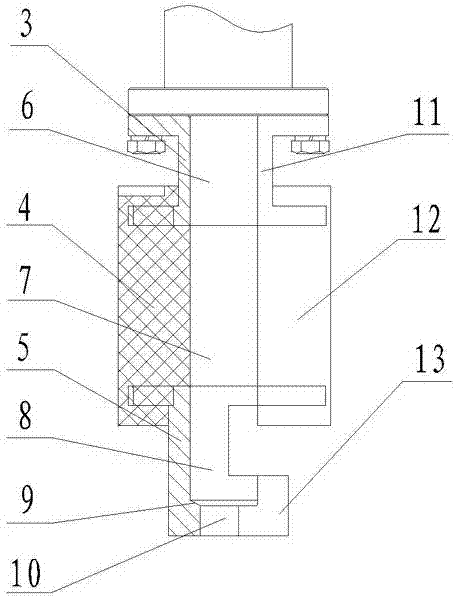

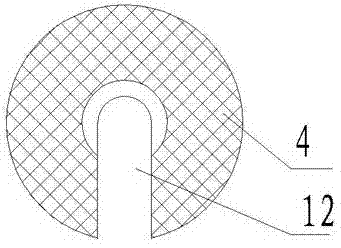

[0012] exist figure 1 Among them, a drill rod buffer device for a hydraulic rock drill, which includes a head body 1 of the rock drill and a shank 2 installed in the head body 1 for installing a drill rod.

[0013] Such as figure 1 As shown, the cross-section of the inner cavity of the shank 2 is a hexagon that coincides with the tail of the drill rod.

[0014] exist figure 1 Among them, a drill rod buffer device for a hydraulic rock drill, which also includes an upper coupling plate 3 , a buffer body 4 and a lower coupling plate 5 . The upper coupling disc 3 and the lower coupling disc 5 are made of metal materials, and the buffer body 4 is made of rubber or other elastic materials.

[0015] Such as figure 1 As shown, the upper end of the upper coupling disc 3 is connected to the end flange of the head body 1, the lower end of the upper coupling disc 3 is fixedly connected to one end of the buffer body 4, and the upper end of the lower coupling disc 5 is fixed to the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com