Preparation method of AlN ceramic base plate for microelectronic packaging

A technology for microelectronic packaging and ceramic substrates, which is applied in the field of microelectronic packaging materials to achieve the effects of uniform composition, uniform grain size, and excellent thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

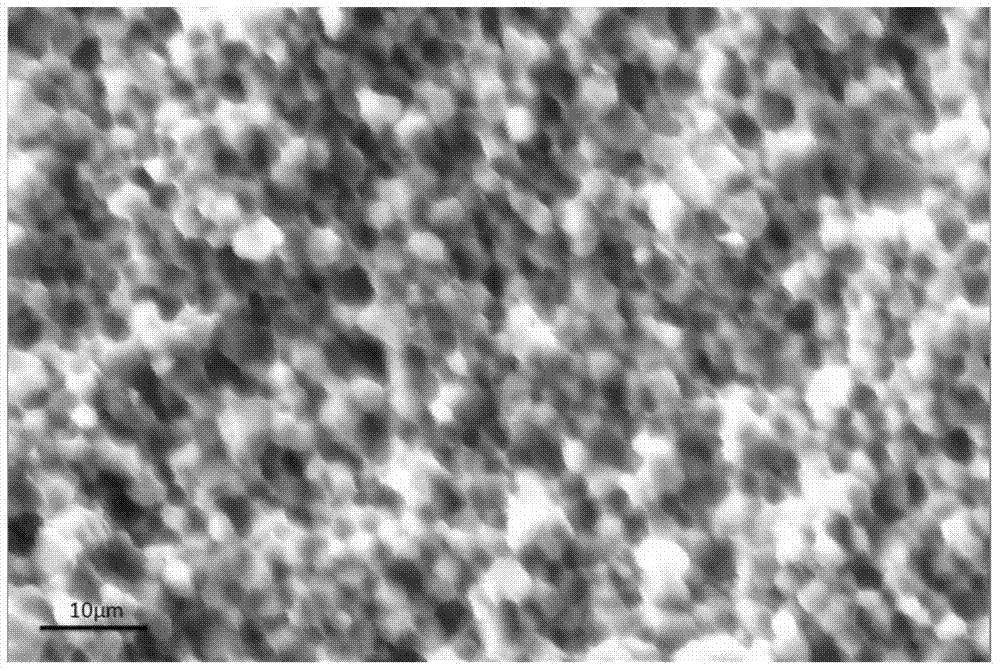

Embodiment 1

[0025] Firstly, the particle size is 1.2 μm and the specific surface area is 3.0 m 2 / g of high-purity AlN powder, the oxygen content is 1.2 wt%, and the components are: AlN 192.0 g, Y(NO 3 ) 3 ·6H 2 O 13.56g, Ca(NO 3 ) 2 4H 2 O 16.84 g;

[0026] Production process: Firstly, the aqueous nitrate is kept at 270°C for 30 minutes, and after dehydration treatment to remove the crystal water in the nitrate, put anhydrous nitrate and 100g alcohol into a ball mill tank, ball mill for 60 minutes, and then add 192.0g AlN powder Body, after ball milling for 180min. Dry in a constant temperature drying oven at 120°C for 2 hours, pass through a 60-mesh sieve; use a muffle furnace, heat the mixed powder at 670°C for 30 minutes for calcination, and pass the calcined powder through a 60-mesh sieve, add 18.5 g of solid paraffin, ℃ uniform heating in a water bath, stirring once every 3 minutes, and a total of 60 minutes in a water bath; after cooling to room temperature, pass through...

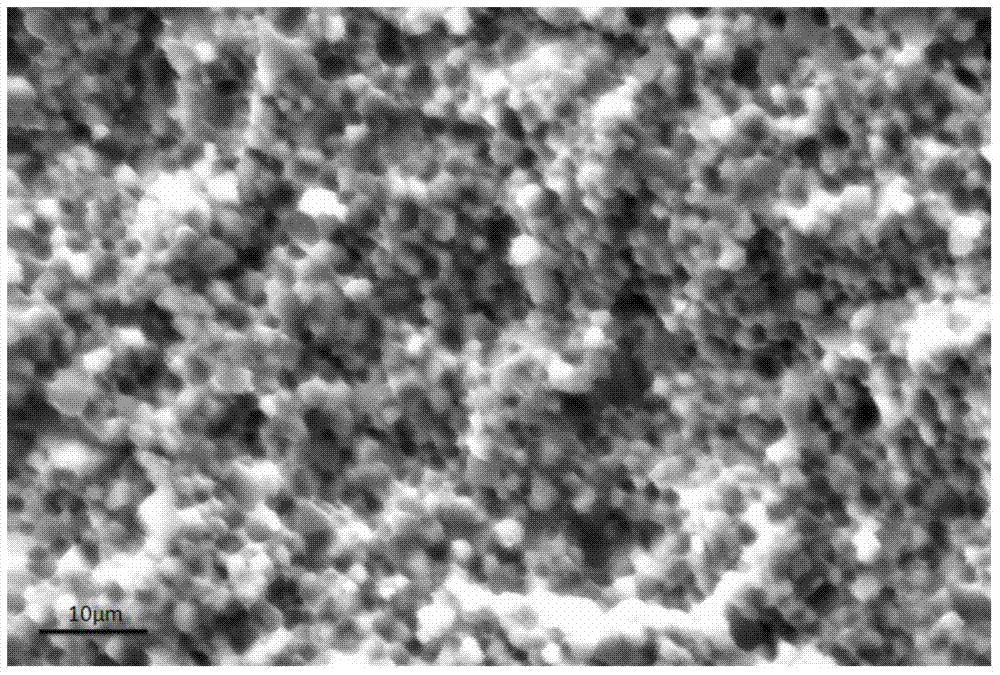

Embodiment 2

[0029] The preparation method of this example is the same as that of Example 1, except that the calcination temperature is 640°C and the sintering temperature is 1650°C.

[0030] Properties of prepared AlN ceramics: thermal conductivity is 114 W m -1 ·K -1 , and the three-point bending strength is 317 MPa.

[0031]

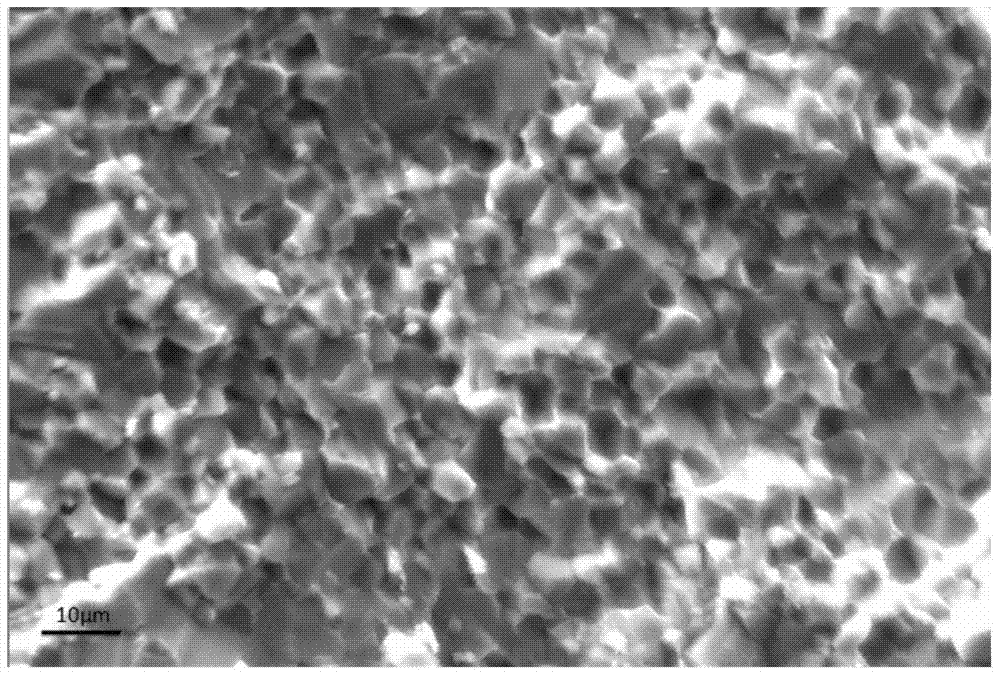

Embodiment 3

[0033] The preparation method of this example is the same as that of Example 1, except that the calcination temperature is 680°C and the sintering temperature is 1800°C.

[0034] Properties of prepared AlN ceramics: thermal conductivity is 109W·m -1 ·K -1 , The three-point bending strength is 328 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com