Four-freedom-degree three-finger operating parallel mechanism

A technology of degrees of freedom and fingers, applied in the field of robotics, can solve the problems of increasing the working space and dexterity of finger operating positions, and achieve the effect of large operating force, less degrees of freedom, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

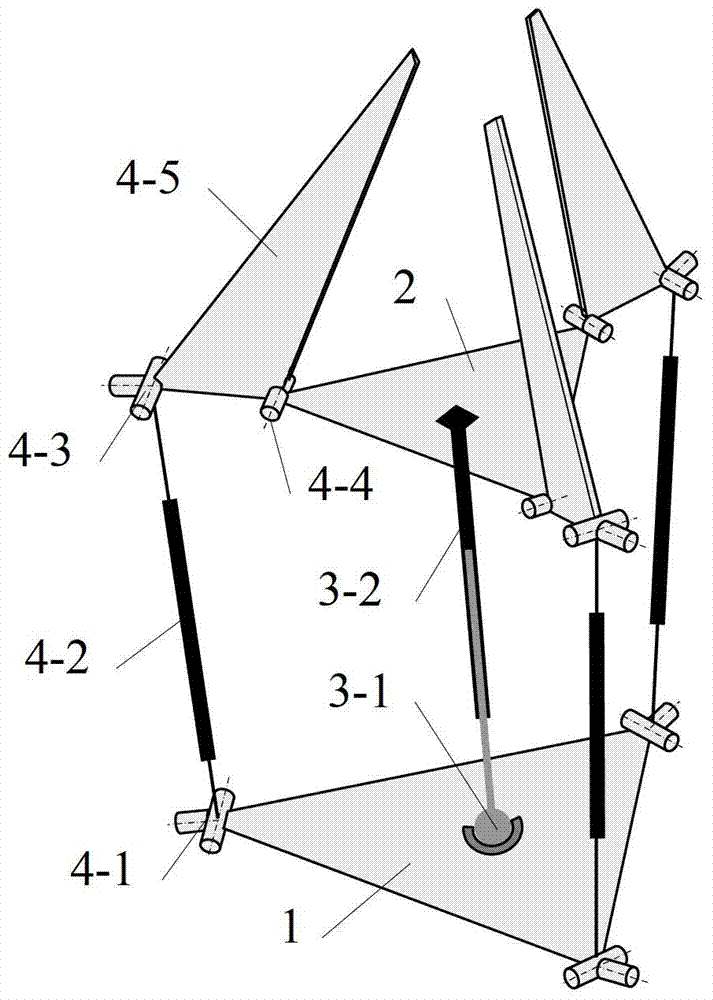

[0013] exist figure 1 In the schematic diagram of a four-degree-of-freedom three-finger operation parallel mechanism shown, one end of the SP-type linear drive branch is connected to the center of the base 1 through the ball pair 3-1, and the other end is connected to the center of the moving platform 2 through the moving pair 3-2. Vertical fixed connection; three UPUR-type finger drive branches with the same structure are uniformly distributed on the circumference between the machine base and the moving platform; one end of the linear drive rod 4-2 in each finger drive branch passes through the universal joint 4-1 and The base is connected, the other end of which is connected with one end of the finger link 4-5 through the universal joint 4-3, the middle part of the finger link is connected with the moving platform through the rotating pair 4-4, and the other end of the finger link is At the free end, the swing surface of each finger link is perpendicular to the moving platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com