Stator winding, motor stator and motor

A technology of stator winding and phase winding, which is applied in the field of stator winding, motor stator and motor, can solve the problems of excessive heat dissipation of bridge wires, low motor power, high loop current, etc., and achieve reduction of bridge wires, high processing efficiency, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

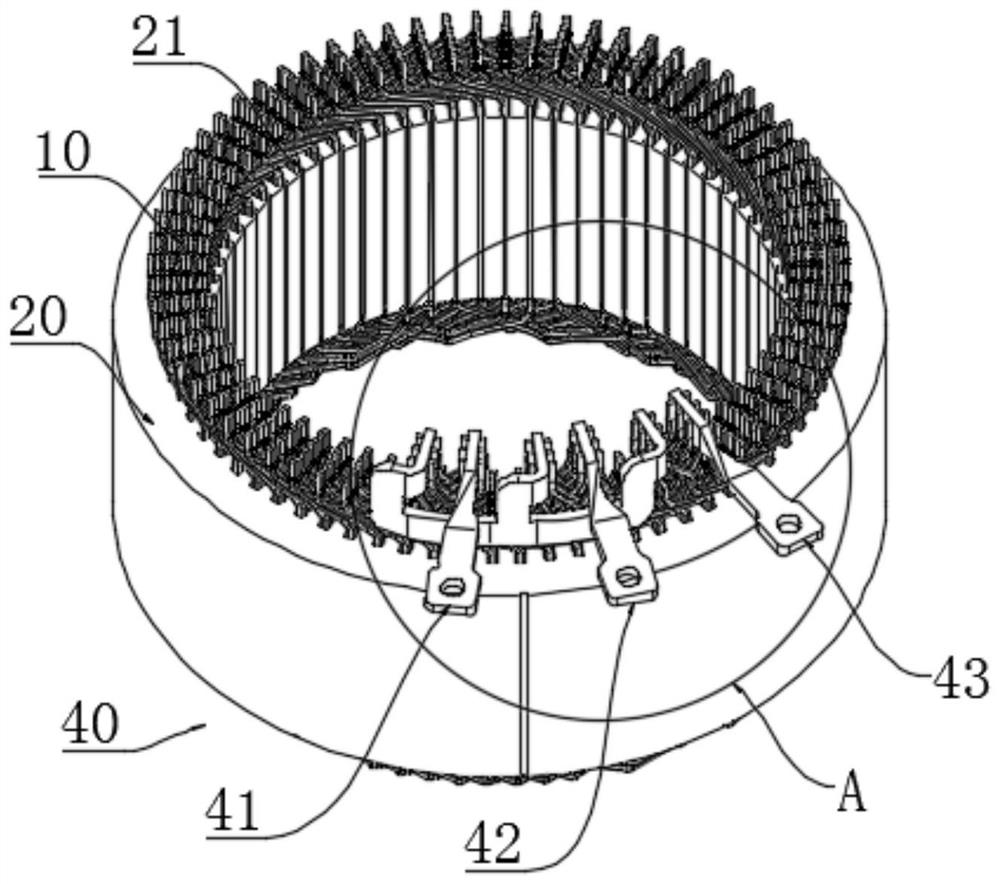

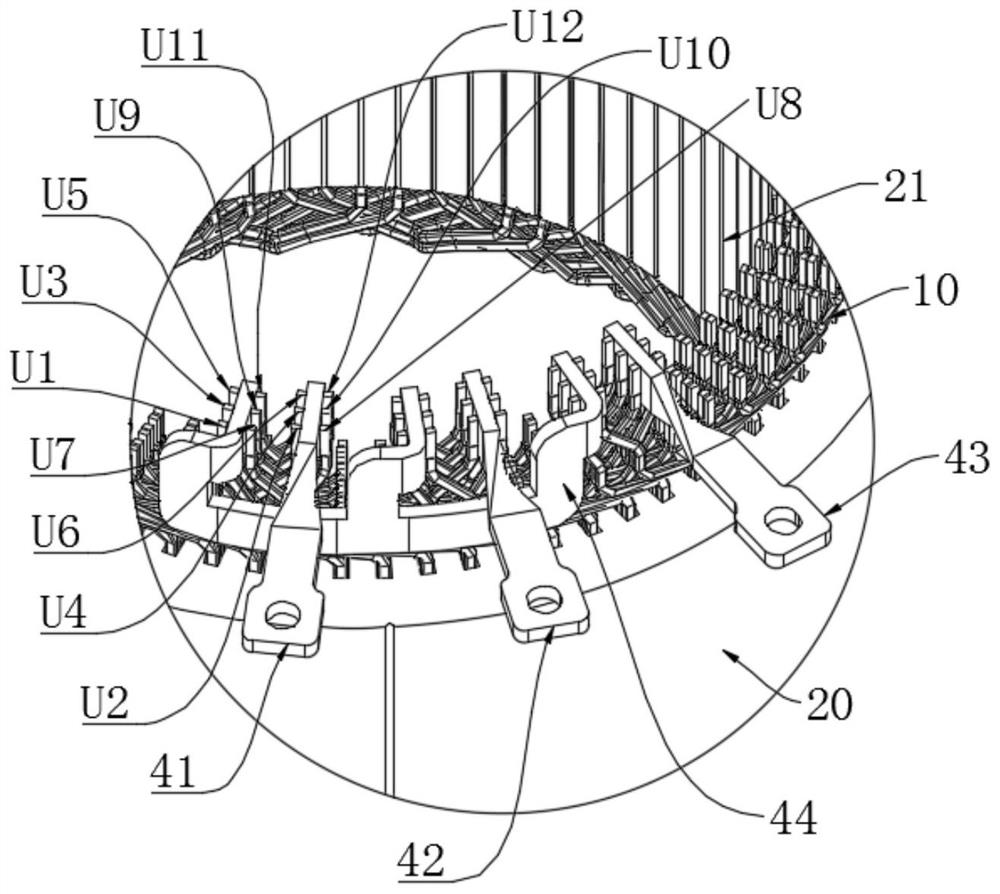

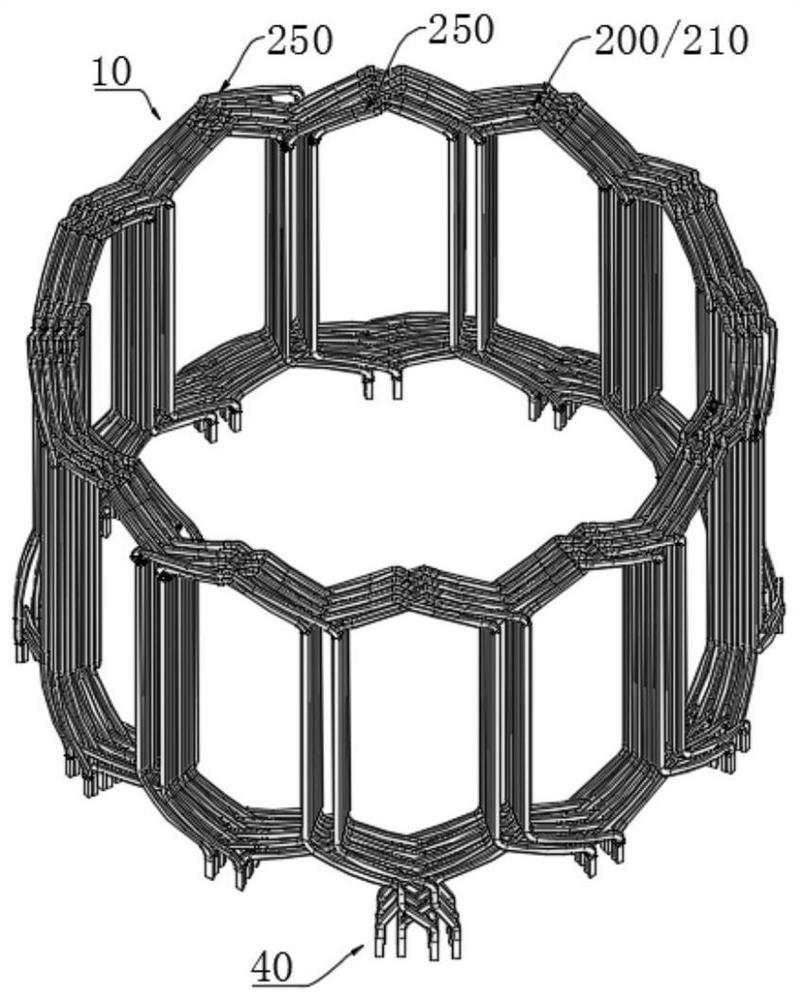

[0054] A stator winding 10 proposed in this embodiment, such as figure 1 , figure 2 with image 3 As shown, installed on the stator core 20, wherein the stator core 20 has a plurality of slots 21, the slots 21 are arranged on the radial inner surface of the stator core 20 and along the circumferential direction of the stator core 20 in a predetermined The slots are spaced apart; the stator winding 10 is U, V and W three-phase, and the hairpin coils in the stator winding 10 of each phase are connected in parallel with 6Y branches along the circumference of the stator core, and the number of slots per pole and phase is 2; and the three-phase Each branch in the winding is connected in parallel sequentially along the circumferential direction of the stator core, Y is an integer and ≥ 1. In this embodiment, if Y is selected as 1, then each pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com